Polyethylene glycol wood powder composite phase change material (PCM) and preparation method and applications thereof

A polyethylene glycol and composite phase change technology, applied in heat exchange materials, chemical instruments and methods, etc., can solve the problems of increasing thermal resistance, reducing PEG phase change enthalpy, high injection molding processing temperature, etc., to achieve the goal of reducing usage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

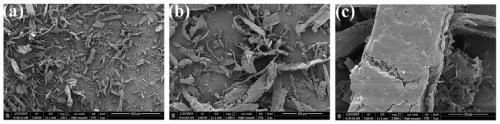

Embodiment 1

[0027] Heat polyethylene glycol with an average molecular weight of 15,000 to 80°C to melt, then add wood powder to the melted polyethylene glycol under vigorous stirring at a speed of 3,000r / min, and stir for 60 minutes under heating at 80°C to mix evenly. Finally, the sample was placed in a vacuum oven with a temperature of 80°C and a pressure of -85KPa for vacuum adsorption for 24 hours to obtain a polyethylene glycol wood powder composite phase change energy storage material. Wherein the wood powder is superfine pine wood powder with an average particle size of 16 μm and a mass content of 35% in the phase change material.

Embodiment 2

[0029] Heat polyethylene glycol with an average molecular mass of 10,000 to 85°C to melt, then add wood powder to the melted polyethylene glycol under vigorous stirring at a speed of 2,000r / min, and stir for 30 minutes under heating at 85°C to mix evenly. Finally, the sample was placed in a vacuum oven with a temperature of 85° C. and a pressure of -85 KPa for vacuum adsorption for 23 hours to obtain a polyethylene glycol wood powder composite phase change energy storage material. Wherein the wood powder is pine wood powder fiber with an average particle size of 10 μm and a mass content of 30% in the phase change material.

Embodiment 3

[0031] Heat polyethylene glycol with an average molecular weight of 8000 to 80°C to melt, then add wood powder to the melted polyethylene glycol under vigorous stirring at a speed of 3000r / min, stir for 45 minutes under heating at 85°C, and mix well. Finally, the sample was placed in a vacuum oven with a temperature of 85°C and a pressure of -85KPa for vacuum adsorption for 22 hours to obtain a polyethylene glycol wood powder composite phase change energy storage material. Wherein the wood powder is superfine poplar wood powder with an average particle size of 15 μm and a mass content of 25% in the phase change material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com