Polyester film heddle

A polyester film and heald technology, applied in the field of plastic healds, can solve the problems of heavy weight, affect the performance of finished products, low stiffness, etc., and achieve the effects of light weight, easy recycling and good comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

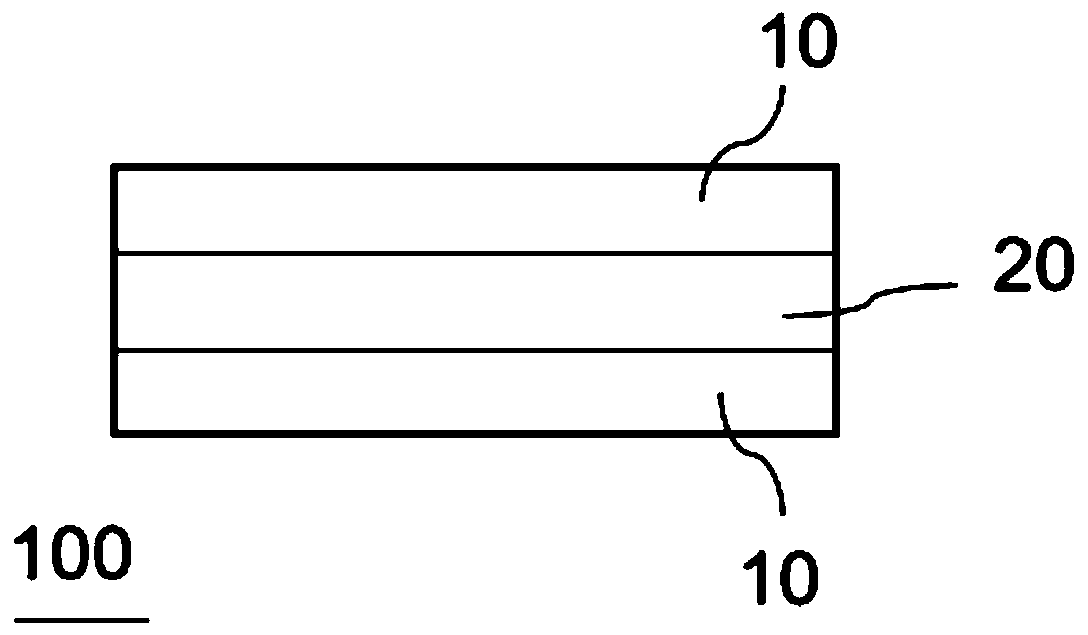

[0041] Polyester film heddle 100 comprises coextruded two surface layers 10 and the core layer 20 between two surface layers 10, and the component of described surface layer 10 comprises: PETG, 189.7kg; Anti-blocking masterbatch, 32.5kg; Color masterbatch , 2.8kg; The components of the core layer 20 include: semi-dull polyester chips, 2115kg; color masterbatch, 120kg; softening agent, 15kg; the color masterbatch in the surface layer 10 and the core layer 20 Comprising polyester chips and pigments, the semi-dull polyester chips of the core layer 20 contain titanium dioxide.

[0042] The surface layer 10 and the core layer 20 form a composite slab, and the composite slab is cast, biaxially stretched, heat-set and rolled to obtain the polyester film with a thickness of 350 μm. After testing, the dynamic friction The coefficient is 0.22.

Embodiment 2

[0044]Polyester film heddle 100 comprises coextruded two surface layers 10 and the core layer 20 between two surface layers 10, and the component of described surface layer 10 comprises: PETG, 180.1kg; Anti-blocking masterbatch, 20.2kg; Color masterbatch , 1.7kg; PTT fiber, 1.4kg; the components of the core layer 20 include: semi-dull polyester chips, 1910kg; color masterbatch, 135kg; softening agent, 13kg; modified PET elastic agent, 41.2kg; The softening agent is polypropylene, the color masterbatch in the surface layer 10 and the core layer 20 includes polyester chips and pigments, and the semi-dull polyester chips in the core layer 20 contain titanium dioxide.

[0045] The surface layer 10 and the core layer 20 form a composite slab, and the composite slab is cast, biaxially stretched, heat-set and rolled to obtain the polyester film with a thickness of 400 μm. After testing, the dynamic friction The coefficient is 0.29.

[0046] All in all, the polyester film heald 100 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com