Finishing technology for efficiently improving wet-state tearing strength of viscose-type fabric

A technology of tearing strength and viscose, applied in fiber processing, plant fibers, textiles and papermaking, etc., can solve problems such as poor wet strength, improve wet tearing strength, improve wet tearing strength, and feel soft. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 Fabric: 29153 viscose crepe cloth Weight: 112g / m 2

[0024] (1) Resin finishing: enter water into the rolling groove of the sizing machine, mix polypolycarboxylic acid and water to form a resin finishing solution, the mass percentage content of polypolycarboxylic acid is 15%, and the viscose fabric is pad-rolled through the rolling groove of the sizing machine Finishing liquid, the rolling rate is kept at 70%, and then the setting machine is dried at a drying temperature of 170°C and a drying time of 100s, and the fabric is wound;

[0025] (2) Soft finishing: mix amino silicone oil Topsoft EP 1218 and water to form a soft finishing solution and add it to the tank of the sizing machine, wherein the mass percentage content of the softener is 2%, and the viscose fabric is rolled by the sizing machine to pad the finishing solution , The excess rolling rate is kept at 70%, and then the setting machine is dried at a drying temperature of 130°C and a drying time ...

Embodiment 2

[0029] Example 2 Fabric: 23336 viscose crepe cloth Weight: 124g / m 2

[0030] (1) Resin softening and finishing in the same bath: enter water into the rolling groove of the sizing machine, mix epoxy resin, smoothing agent Megasoft CEC and water to form a resin finishing solution, wherein the mass percentage content of epoxy resin is 15%, and the content of softening agent The mass percentage content is 2%, the viscose fabric is passed through the sizing machine to pad the finishing solution, and the excess rate is kept at 70%, and then the sizing machine is dried at a drying temperature of 170°C and a drying time of 100s. , inspect, pack and ship.

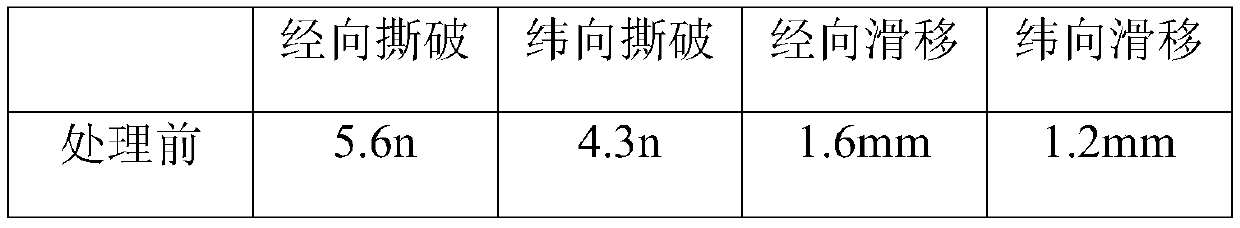

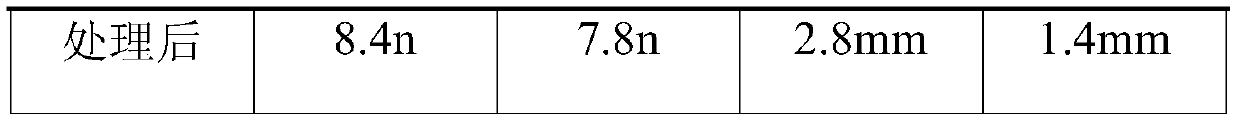

[0031] (2) Comparison of wet tear strength of fabrics before and after treatment:

[0032]

[0033] Note: Test strength test standard JIS L 1096D (wet state), slip test standard: JIS L 1096B (fixed load 49n).

Embodiment 3

[0034] Example 3 Fabric: 015 viscose crepe cloth Weight: 116g / ㎡

[0035] (1) Resin finishing: enter water into the rolling groove of the sizing machine, mix the thiourea resin and water to form a resin finishing solution, the mass percentage content of the thiourea resin is 12%, and the viscose fabric is soaked in the finishing solution through the rolling groove of the sizing machine , the excess rolling rate is kept at 70%, and then the setting machine is dried, the drying temperature is 175°C, the drying time is 120s, and the fabric is wound;

[0036] (2) Soft finishing: mix the silicone oil TWSOFT PM for hemp and water to form a softening finishing liquid and add it to the tank body of the sizing machine, wherein the mass percentage content of the softening agent is 2%, and the viscose fabric is rolled by the sizing machine to pad the finishing liquid , the excess rolling rate is maintained at 70%, and then the setting machine is dried at a drying temperature of 120°C and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com