Method for preparing in-situ transmission electron microscope sample based on heated chip

A technology for TEM samples and heating chips, applied in the preparation of test samples, metal processing equipment, electron beam welding equipment, etc., can solve problems such as sample damage, improve yield, increase sample preparation efficiency, and ensure sample quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

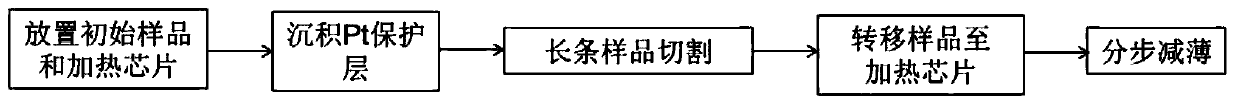

[0048] figure 1 A flow chart showing a heating chip-based in-situ transmission electron microscope sample preparation method according to an exemplary embodiment of the present invention, as figure 1 As shown, according to an exemplary embodiment of the present invention, the heating chip-based in-situ TEM sample preparation method mainly includes the following steps.

[0049] Step A:

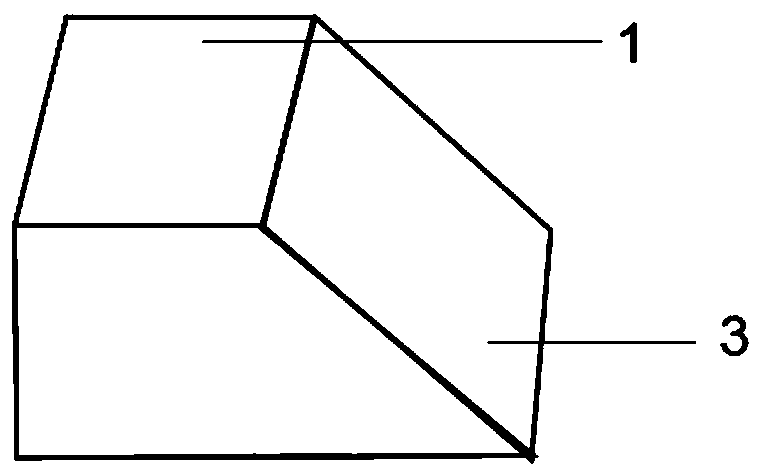

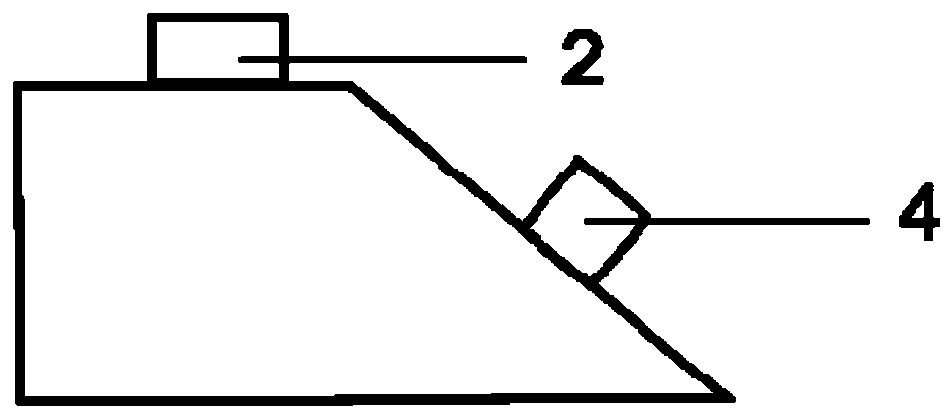

[0050] The initial sample 2 and the heating chip 4 are respectively fixed on the adjacent plane 1 and slope 2 on the prefabricated sample stage 11, and then the prefabricated sample stage 11 is transferred to the FIB-SEM dual-beam system and vacuumized.

[0051] Figure 2a It shows a schematic structural view of the prefabricated sample stage in the in-situ transmission electron microscope sample preparation method based on the heating chip according to an exemplary embodiment of the present invention, Figure 2b A schematic diagram showing the position of the initial sample and the heating ...

Embodiment 1

[0087] Figure 7a Showing the microscopic topography figure of depositing the Pt protection layer on the initial sample in embodiment 1, Figure 7b It shows the microscopic topography diagram of etching a deep groove at one end edge of the Pt protective layer of the initial sample deposited with the Pt protective layer in Example 1, Figure 7c Shown in embodiment 1 in the initial sample that is deposited with Pt protection layer, the microcosmic topography figure of one side etching cutting of strip sample is carried out on one side edge of Pt protection layer, Figure 7d It shows the microscopic topography diagram of etching and cutting the other side of the strip sample at the edge of the other side of the Pt protective layer of the initial sample deposited with the Pt protective layer in Example 1, Figure 7e Shown in embodiment 1 is adjusted the microscopic topography figure that the strip sample surface is perpendicular to the ion beam direction, Figure 7f Showing the...

Embodiment 2

[0102] Figure 10a A microscopic topography diagram of etching a deep groove at one end edge of the Pt protective layer of the initial sample deposited with the Pt protective layer in Example 2 is shown, Figure 10b Shown in embodiment 2 is deposited on the Pt protective layer side edge of the initial sample of Pt protective layer and carries out the microscopic topography figure of one side etching cutting of strip sample, Figure 10c Shown in embodiment 2 in the other side edge of the Pt protective layer of the initial sample deposited with the Pt protective layer, the microscopic topography of the other edge of the strip sample is etched and cut, Figure 10d The microscopic topography diagram of adjusting the surface of the strip sample perpendicular to the direction of the ion beam in Example 2 is shown.

[0103] In this embodiment, aluminum (Al) thin film is selected as the material for preparing the sample, and the in-situ heating TEM sample is prepared based on the in-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Etching depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com