Programmable multi-core optical fiber low-light hand

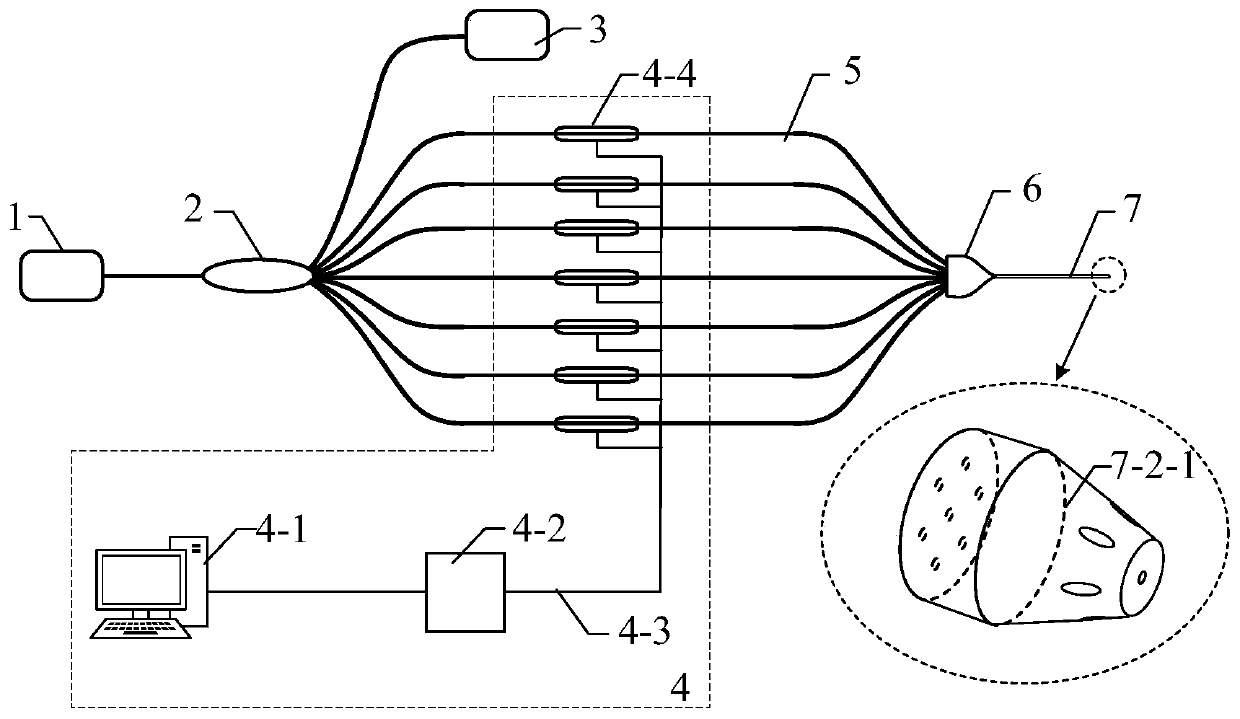

A multi-core fiber, low-light technology, applied in cladding fiber, optical waveguide light guide, nuclear engineering, etc., can solve the problem of single particle manipulation technology, and achieve the effect of good operation flexibility, reduced size, and high integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

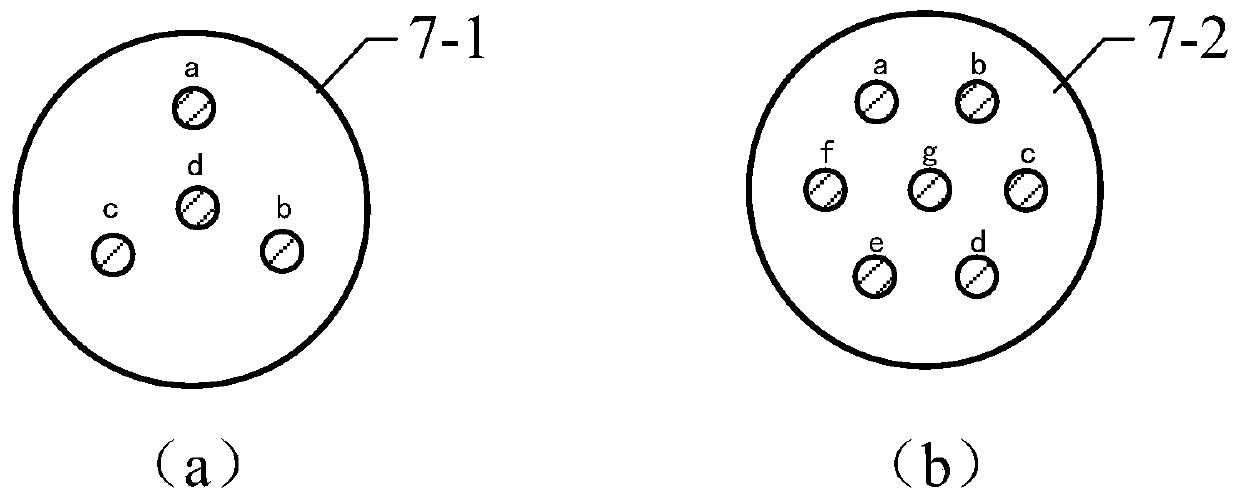

[0025] Example 1: Stable capture of particles.

[0026] Such as Figure 4 , Figure 5 and Figure 6 As shown in (a) and (b), through the programmable module, the stable capture of particles 8 can be realized by controlling the light transmission conditions in the cores a-f of the seven-core fiber micro-light hand 7 annular distribution. Whether it is Figure 4 All the six cores a-f in (a) and (b) pass through the light, or Figure 5 The three cores a, c, and e in (a) and (b) pass through the light, or Figure 6 The four cores a, b, d, and e in (a) and (b) are light-passing. As long as the outgoing converged light field is symmetrical, stable capture of particles 8 can be achieved.

Embodiment 2

[0027] Example 2: Particle directional ejection.

[0028] Such as Figure 4 As shown, (a) (b) represents the stable capture of particles 8, (c) (d) represents the principle of particle directional ejection, and (e) represents the change of light passing through each core with time.

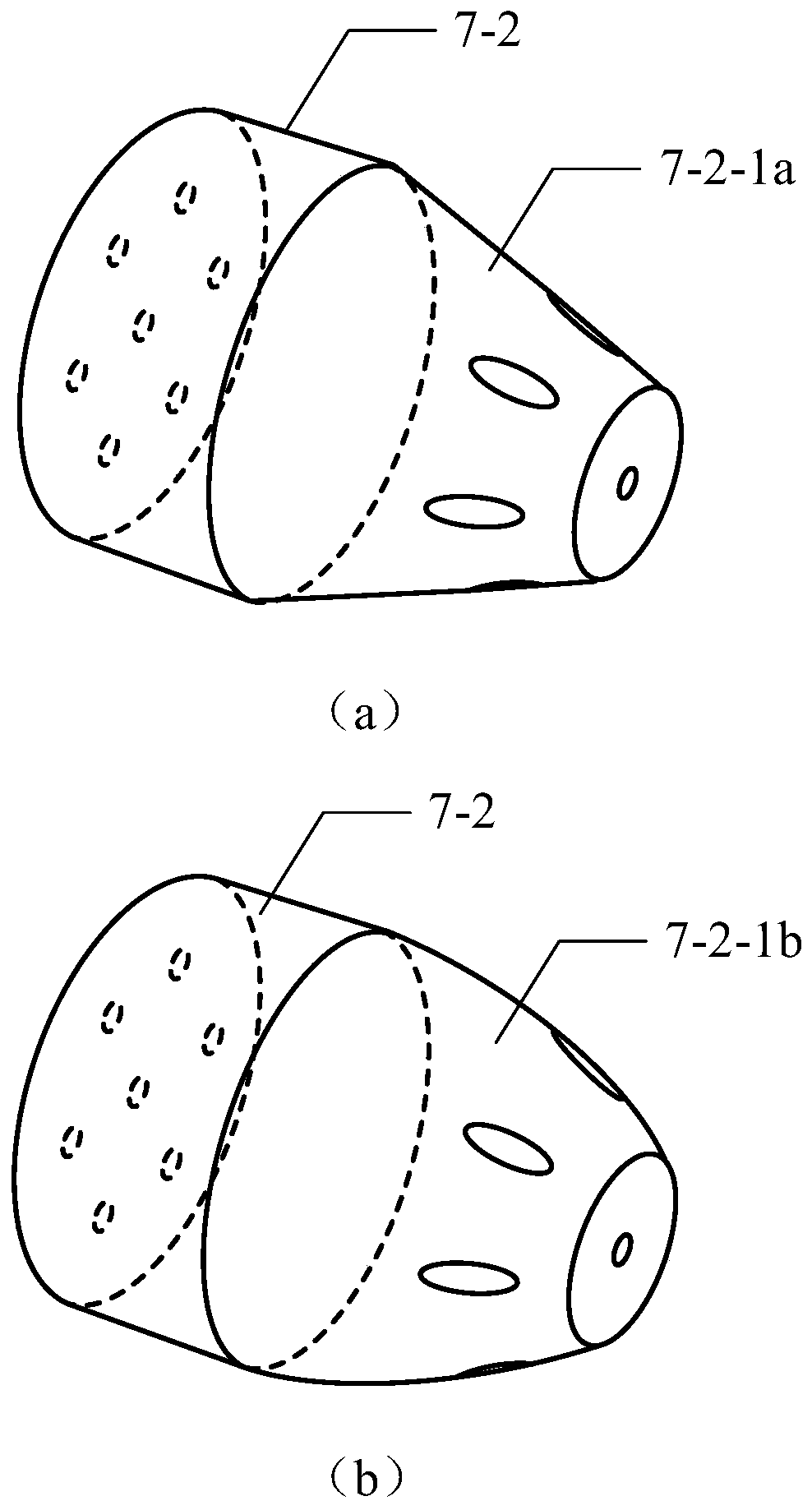

[0029] Firstly, the programmable control module 4 controls the core channels a-f to pass into the light beam 7-2-2 of equal power, and the light beam is reflected and focused by the rotationally symmetrical frustum structure 7-2-1 on the end face to form a stable trapping potential well for particle 8 for stable capture. At this time, the middle fiber core channel g is blocked from light. Next, adjust the position and direction of the optical fiber micro-light hand 7-2, and aim at the direction where the particles are to be ejected. Finally, through the programmable control module 4, the intermediate core channel g passes through a relatively high-power beam 7-2-3, as shown in Figure (c)(d), the ...

Embodiment 3

[0030] Example 3: Rotation of particles.

[0031] Such as Figure 5 , where (a) (b) represents the stable trapping of particles, (c) (d) represents the principle of particle rotation operation, and (e) represents the change of light passing through each core with time.

[0032] Firstly, the control module 4 controls the fiber core channels a, c, e to pass in light beams 7-2-2 of equal power, and the other fiber core channels are not connected to light. The light beam is reflected and focused by the rotationally symmetrical truncated cone structure 7-2-1 on the end face, forming a stable trapping potential well, and stably trapping the particle 8 . Then the control module 4 controls the core channels a, c, e to pass through the continuous stable beam 7-2-2, and the core channels b, d, f to pass through the sequence pulsed light 7-2-3 in turn, as shown in figure (e). Each beam of pulsed light can give a transverse momentum to the stably trapped particle 8, so the sequence puls...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com