A lead-free double perovskite single crystal ultraviolet light detector and its preparation method

A lead-free double perovskite and double perovskite technology, which is applied in semiconductor/solid-state device manufacturing, photovoltaic power generation, electric solid-state devices, etc., can solve problems such as instability and high lead toxicity, and achieve good performance and excellent performance. Effects of photoelectric properties and rapid UV response

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

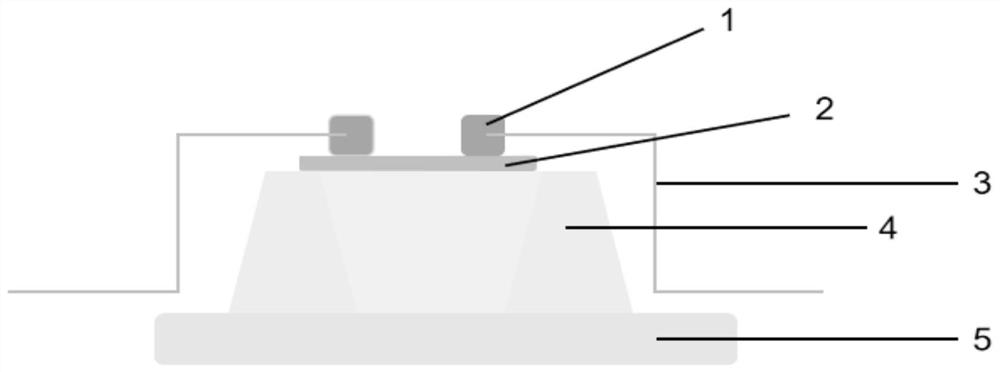

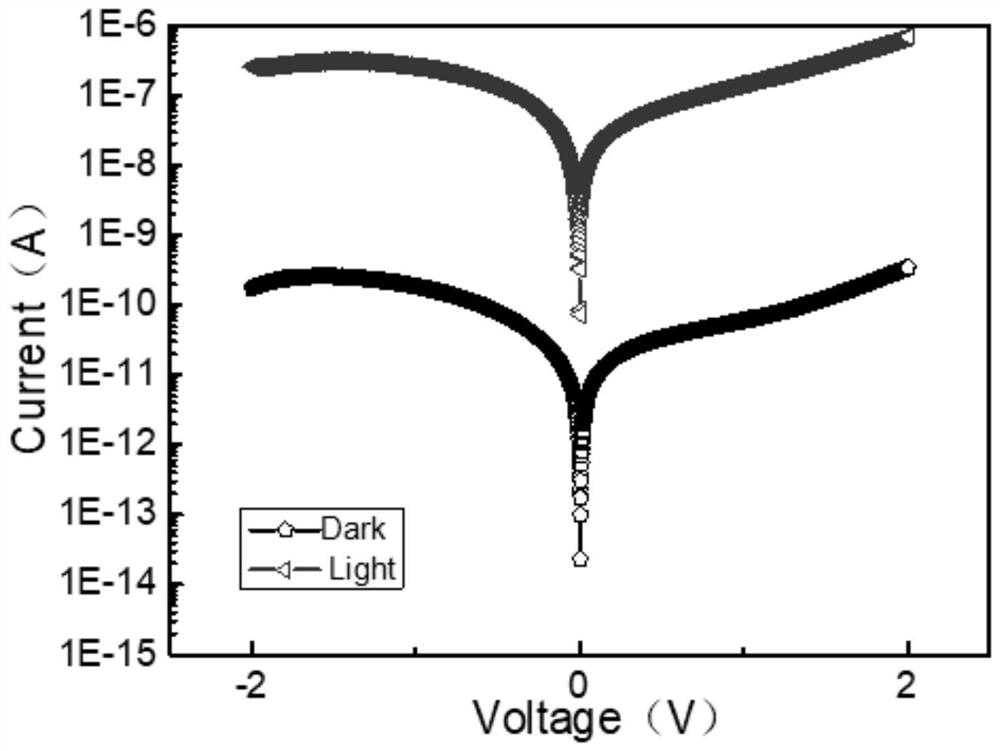

[0038] Embodiment 1, preparation Cs 2 AgInCl 6 Single-crystal double perovskite ultraviolet photodetectors

[0039] 1) Configure Cs 2 AgInCl 6 Precursor solution

[0040] Weigh 0.0674g CsCl, 0.0443g InCl 3 Mix with 0.0287g AgCl and dissolve in 4.8mL of hydrochloric acid, heat at 140°C-160°C for 5h until the solution is clear and completely dissolved.

[0041] 2) Preparation of Cs 2 AgInCl 6 single crystal

[0042] The specific steps are: the above Cs 2 AgInCl 6 The precursor solution was cooled and crystallized three times. In the first stage, the temperature was reduced to 110°C at a rate of 2°C / h, and in the second stage, the temperature was reduced to 60°C at a rate of 1°C / h, and then heated at 60°C for 5 hours. Finally, in the third stage, the temperature is rapidly lowered to room temperature at a rate of 5 °C / h until a lead-free perovskite single crystal with a size of about 3 mm is produced.

[0043] 3) Cs 2 AgInCl 6 Fabrication of Single Crystal Devices

...

Embodiment 2

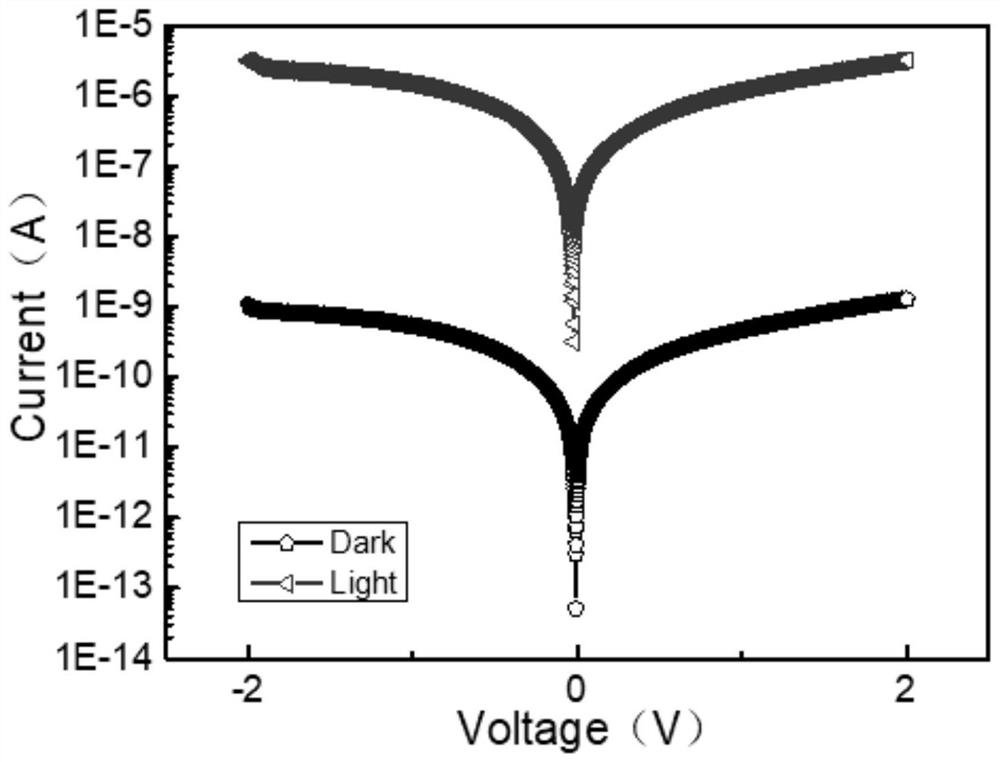

[0048] Embodiment 2, preparation Cs 2 NaInCl 6 Single-crystal double perovskite ultraviolet photodetectors

[0049] 1) Configure Cs 2 NaInCl 6 Precursor solution

[0050] Weigh 0.0674gCsCl, 0.0443gInCl 3 Mix with 0.0117g NaCl and dissolve in 3mL of hydrochloric acid, heat at 140°C-160°C for 5h until the solution is clear and completely dissolved.

[0051] 2) Preparation of Cs 2 NaInCl 6 single crystal

[0052] The specific steps are: the Cs 2 NaInCl 6 The precursor solution was cooled and crystallized three times. In the first stage, the temperature was reduced to 110°C at a rate of 2°C / h, and in the second stage, the temperature was reduced to 60°C at a rate of 1°C / h, and then heated at 60°C for 5 hours. Finally, in the third stage, the temperature is rapidly lowered to room temperature at a rate of 5 °C / h until a lead-free perovskite single crystal with a size of about 3 mm is produced.

[0053] 3) Cs 2 NaInCl 6 Fabrication of Single Crystal Devices

[0054] Cl...

Embodiment 3

[0058] Embodiment 3, prepare MA 2 AgBiI 6 Crystal double perovskite ultraviolet photodetectors

[0059] 1) Configure MA 2 AgBiI 6 Precursor solution

[0060] Weigh 0.0790g MAI, 0.2950g BiI 3 Mix with 0.1175AgI and dissolve in 2mL of hydroiodic acid, heat at 140°C-160°C for 5h until the solution is clear and completely dissolved.

[0061] 2) Preparation of MA 2 AgBiI 6 single crystal

[0062] The specific steps are: put the MA 2 AgBiI 6 The precursor solution was crystallized by cooling down three times. In the first stage, the temperature was lowered to 110°C at a rate of 2°C / h, and in the second stage, the temperature was lowered to 60°C at a rate of 1°C / h, followed by continuous heating at 60°C for 5 hours. , and finally the third stage rapidly lowers to room temperature at a rate of 5 °C / h until a lead-free perovskite single crystal with a size of about 3 mm is produced.

[0063] 3) MA 2 AgBiI 6 Fabrication of Single Crystal Devices

[0064] Clean the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com