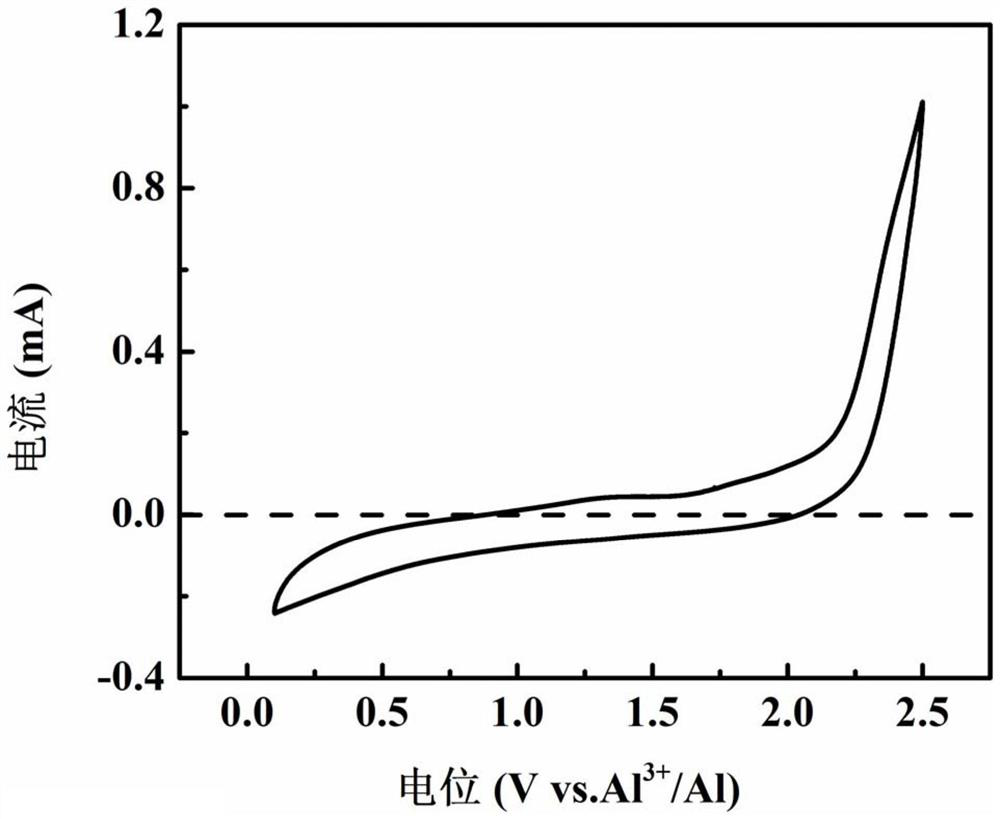

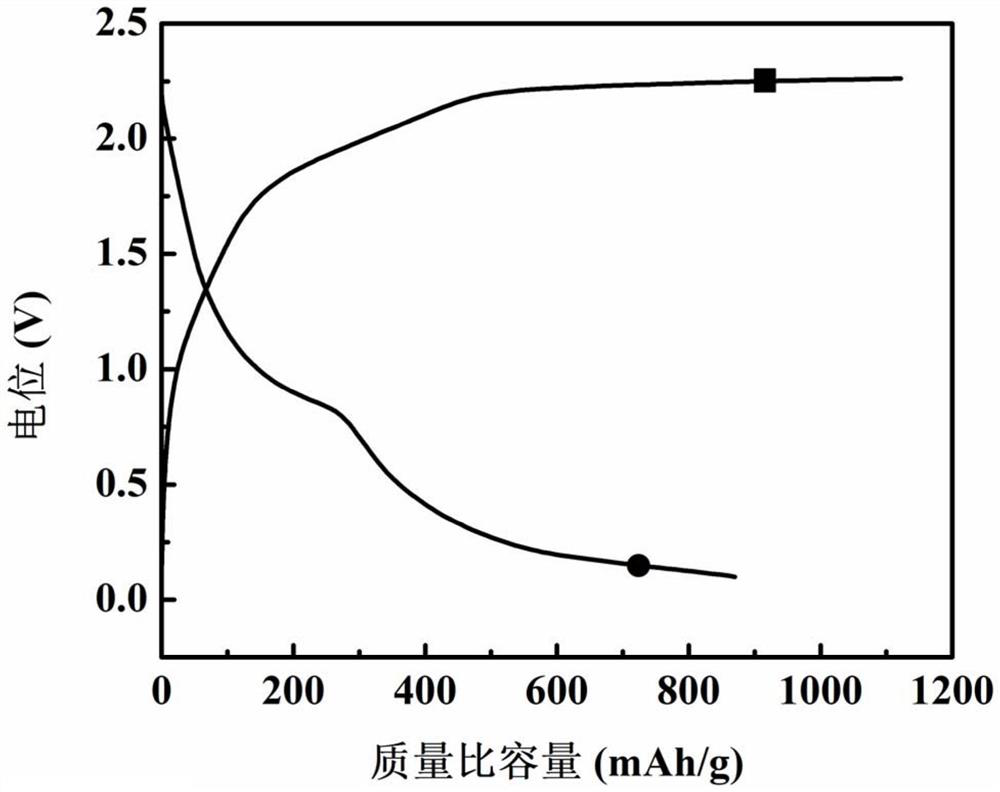

Preparation method and application method of positive electrode material for high-capacity aluminum battery

A technology for positive electrode materials and aluminum batteries, applied in battery electrodes, secondary batteries, battery components, etc., can solve problems such as limited theoretical capacity, complicated process flow, and obstacles to application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] Using the drop casting method, graphene oxide-carbon fiber film is made with graphene oxide aqueous phase dispersion and carbon fiber, the carbon fiber is placed on the cellulose filter membrane, and the graphene oxide aqueous phase dispersion is added dropwise on the carbon fiber, and the graphite oxide Graphene and carbon fiber composite; the concentration of graphene oxide aqueous dispersion is 1mg / mL, and the diameter of carbon fiber is ≤10μm; the dosage ratio of graphene oxide aqueous dispersion and carbon fiber is 1:1 according to the mass ratio of graphene oxide and carbon fiber ;

[0052] Dry the graphene oxide-carbon fiber film at room temperature for 60 minutes, and then dry it at 120°C for 24 hours under vacuum to make a dry film;

[0053] Immerse the dried film in hydroiodic acid solution, reduce it at 40°C for 24h, then wash off the acid solution on the surface with deionized water, then wash off the moisture on the surface with absolute ethanol, and finall...

Embodiment 2

[0059] The preparation method of the positive electrode material for high-capacity aluminum batteries is the same as in Example 1, the difference is that:

[0060] (1) Adopt vacuum filtration method, make graphene oxide-carbon fiber film with graphene oxide aqueous phase dispersion liquid and carbon fiber, place carbon fiber on the cellulose filter membrane, then place in the funnel, add graphene oxide aqueous phase to disperse After liquid, graphene oxide and carbon fiber composite, while part of the water is separated by suction filtration; the concentration of graphene oxide aqueous phase dispersion is 2mg / mL; the dosage ratio of graphene oxide aqueous phase dispersion and carbon fiber The mass ratio is 2:1;

[0061] (2) Dry the graphene oxide-carbon fiber film at room temperature for 55 minutes, and then dry it at 130°C and vacuum for 22 hours;

[0062] (3) Reduction at 80°C for 10h, washing with water and alcohol and drying at 150°C under vacuum for 18h; the mass concent...

Embodiment 3

[0068] The preparation method of the positive electrode material for high-capacity aluminum batteries is the same as in Example 1, the difference is that:

[0069] (1) The concentration of graphene oxide aqueous phase dispersion is 2mg / mL; The consumption ratio of graphene oxide aqueous phase dispersion and carbon fiber is 3:1 by the mass ratio of graphene oxide and carbon fiber;

[0070] (2) Dry the graphene oxide-carbon fiber film at room temperature for 50 minutes, and then dry it at 140°C and vacuum for 20 hours;

[0071] (3) Reduction at 100°C for 1h, washing with water and alcohol and drying at 200°C under vacuum for 12h; the mass concentration of HI in the hydroiodic acid solution is 55%;

[0072] (4) Microwave treatment for 10s;

[0073] Using method is the same as embodiment 1, and difference is:

[0074] (1) The electrolyte used in the assembly of aluminum batteries is AlCl 3 - Urea; AlCl in electrolyte 3 The molar percentage of the electrolyte is 57%; the electr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com