Preparation method and application of three-dimensional honeycomb-shaped nano Si

A honeycomb and nanotechnology, applied in electrical components, battery electrodes, circuits, etc., can solve problems affecting battery cycle performance, damage to battery motor structure, electrolyte consumption, etc., to achieve excellent cycle performance, high Coulombic efficiency, and production low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

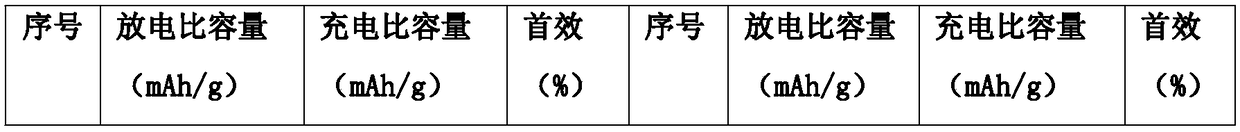

[0020] Example 1: Weigh 10 g of micron-sized Si particle powder with a size d50 of 0.8 μm and add it to the NOˉ electrolyte solution containing Ag ions, emulsify and disperse evenly for 30 minutes, and perform solid-liquid separation by high-speed centrifugation to obtain a relatively dry particle powder , 10g of asphalt powder with the same size d50 and about 1 μm, mixed uniformly by a multi-dimensional high-efficiency ball mill for 30 minutes, put it into a quartz material boat, entered a vacuum horizontal heating furnace, and carried out carbonization coating under the protection of Ar gas, and the carbonization temperature was set at 1100 ℃, constant temperature for 2 hours, naturally cooled to room temperature and taken out to obtain a composite material with 17g of carbon coated on the surface of micron-sized Si particles. The internal Si is etched, drilled and cut synchronously, and the time is controlled within 3 to 5 minutes, followed by rapid solid-liquid separation, ...

Embodiment 2

[0023] Mix the silicon-carbon coated composite material obtained in Example 1 with the existing conventional artificial graphite negative electrode material in a ratio of 1:4 using a high-efficiency multidimensional ball mill for 20 minutes, and make CR2025 button battery pole pieces in the same way as in Example 1 The 28-week cycle was measured by the same cycle method as in Example 1. See Table 2 for details. The first discharge specific capacity is 607.7128mAh / g, the charge specific capacity is 556.7529mAh / g, and the first Coulombic efficiency reaches 91.5%. Charge after 28 cycles The specific capacity retention rate is 98.72%, with little attenuation.

Embodiment 3

[0025] Weigh 10 g of micron-sized Si particle powder with a d50 of 1.3 μm, and add it to Cu-containing SO 4 2-In the ion solution, the concentration of the solution after adding Si particle powder is 0.01mol / L, emulsify and disperse evenly for 30 minutes, and disperse the solid-liquid by high-speed centrifugation to obtain relatively dry powder particles, and then add the graphene oxide solution with a concentration of 0.2wt / g , stirred for 1.5 hours, dried, put into a quartz boat, and entered a vacuum horizontal heating furnace. Under the protection of Ar gas, the temperature was raised to 900°C for carbonization coating, and the temperature was kept at a constant temperature for 2 hours. The temperature was naturally lowered to room temperature and taken out to obtain 10.8g The graphene carbon layer is coated on the composite material of the surface of micron-sized Si particles, and then the composite material is added to deionized water to disperse evenly for 30 minutes, an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| current efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com