Device and method of DIR-SOFC (Direct internal reforming-solid oxide fuel cell) with support of heat pipe

A solid oxide and fuel cell technology, applied in the direction of solid electrolyte fuel cells, fuel cells, fuel cell additives, etc., can solve the problems of reducing the temperature gradient and thermal stress of fuel cells, and achieve the effect of improving performance and life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

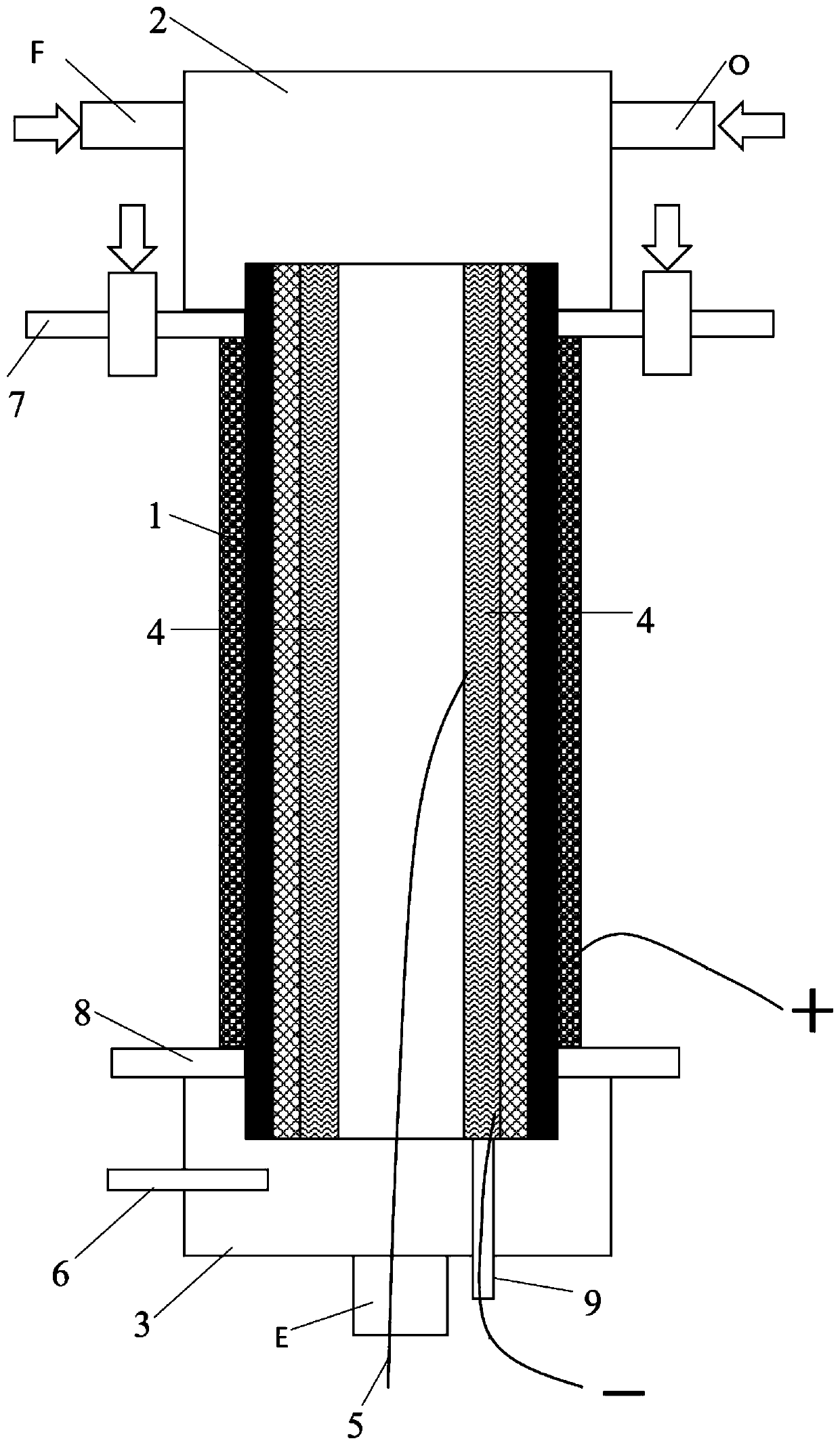

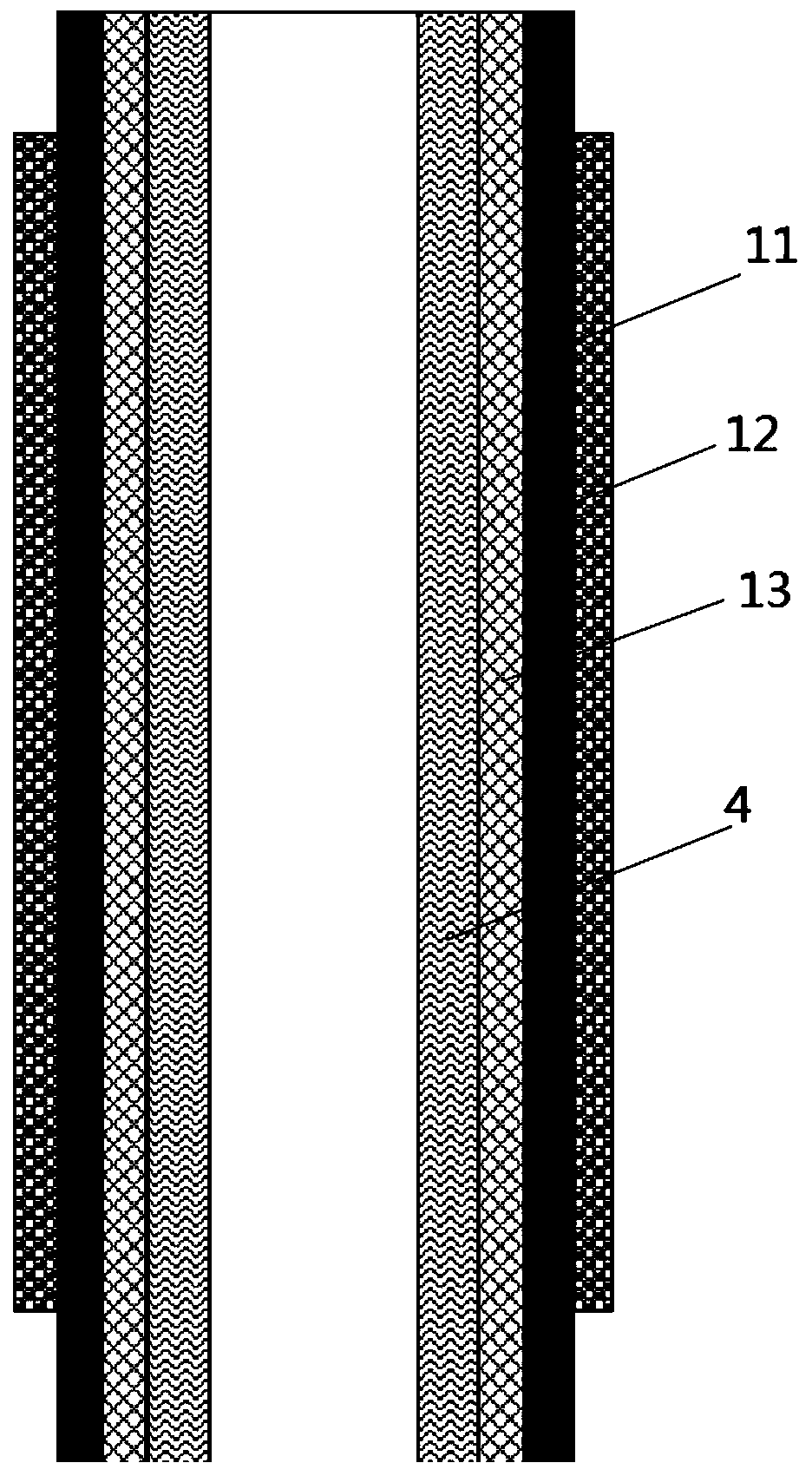

[0035] like figure 1 As shown, the heat pipe supporting direct internal reforming solid oxide fuel cell device of this embodiment includes: a fuel cell 1, an anode premix chamber 2, an anode combustion chamber 3, a high temperature heat pipe 4, a temperature sensor 5, an ignition gun 6, an upper compartment Plate 7 and lower partition 8; wherein, as figure 2As shown, the fuel cell 1 is a tubular solid oxide fuel cell, which sequentially includes a tightly packed cathode 11, a solid oxide electrolyte layer 12, and an anode 13 from the outside to the inside, and the middle of the tubular anode is a gas channel; An anode premix chamber 2 is arranged at the top, an anode combustion chamber 3 is arranged at the bottom of the fuel cell 1, an upper separator 7 is arranged under the anode premix chamber, and a lower separator 8 is arranged on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com