Production method of capsule for energy accumulator

A production method and accumulator technology, which is applied in the production field of capsules for accumulators, can solve the problems of rubber performance indicators such as large discounts, elongation, tensile strength decline, and uneven seams, etc., and achieve performance indicators High, reduced process, stable material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0031] Instance specification: NN6.3X486HG2331-92;

[0032] The preparation of the test piece shall be made according to the provisions of GB9865;

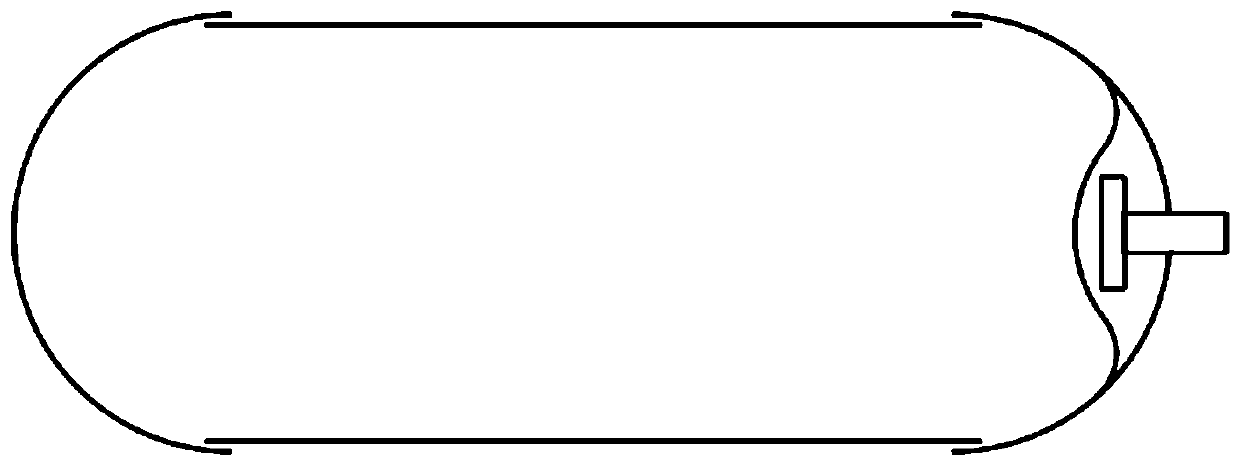

[0033] Firstly extruded by extruder figure 2 The cylindrical rubber cartridge 1 shown;

[0034] Axial length of rubber cartridge 1: 410mm, diameter 130mm, thickness 2.2±0.2mm;

[0035] and then made by the splitting process such as Figure 3 ~ Figure 5 The shown circular back cover sheet 2, the front cover sheet 3 with a circular hole in the middle and the inner cover sheet 4 with a circular hole in the middle;

[0036] Diameter of back cover 2: 152mm, thickness: 2.2mm; diameter of front cover 3: 152mm, thickness: 2.2mm; diameter of inner cover 4: 80mm, thickness: 2.2mm;

[0037] Further, the inner seal 4 is placed parallel to the side of the front seal 3, and the inlet joint 5 of metal material is placed between the inner seal 4 and the front seal 3, and protrudes from the round hole in the middle of the front seal 3, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com