Anti-peeling thermal insulation material, and construction method thereof

A thermal insulation material, anti-shedding technology, applied in covering/lining, building, building structure, etc., can solve problems such as low efficiency, achieve the effect of saving materials, not easy to crack, and reducing the probability of cold shrinkage cracking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

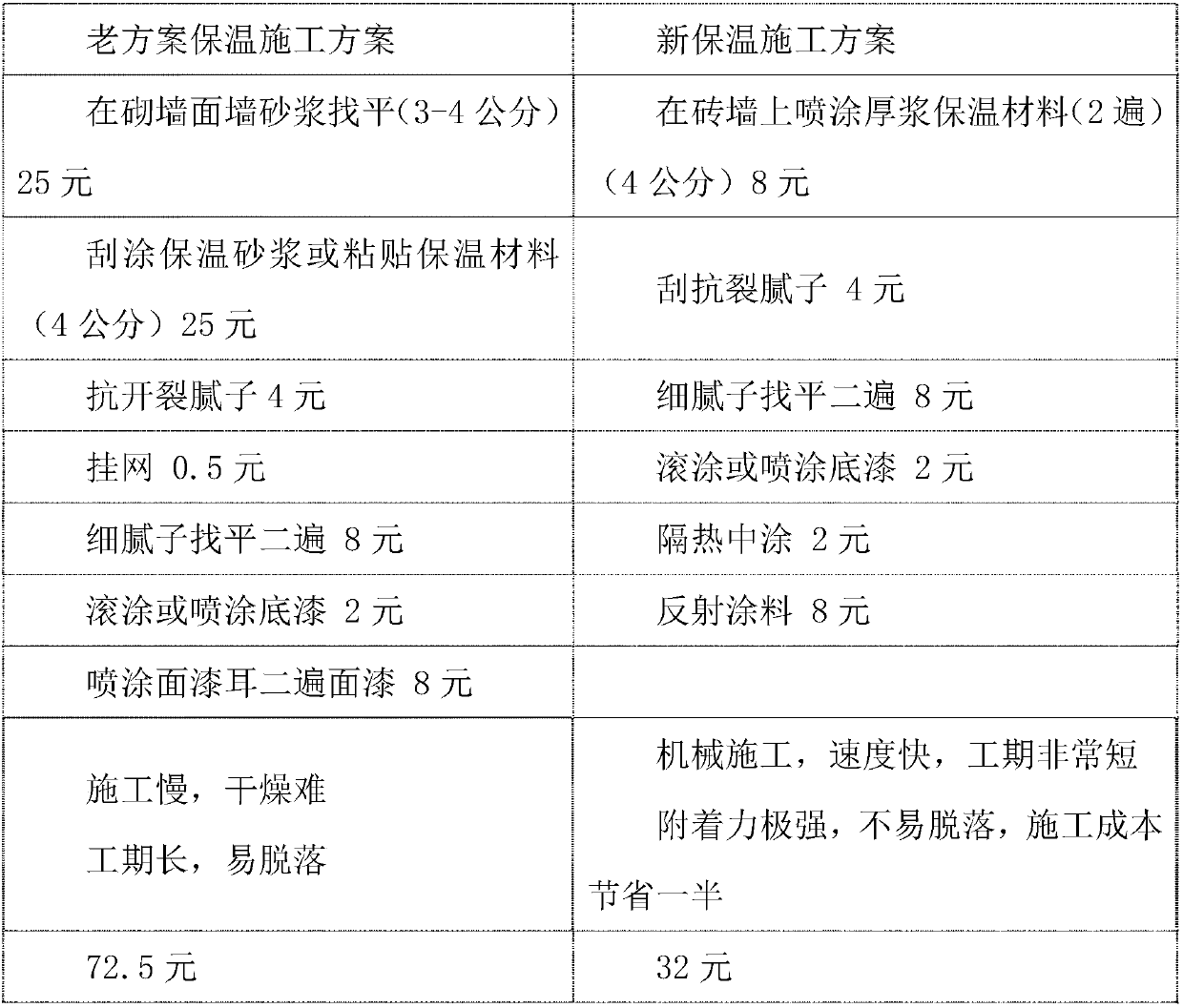

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] An anti-shedding thermal insulation material, including component A and component B, its raw materials are as follows: the component A is 0.8 parts, the component B is 1.0 parts, and the component A includes water, X -405 Alkylphenol Polyoxyethylene Wetting Agent, Ethylene Glycol, BIT Bactericide, Airgel and Lauryl Fat Film-forming Auxiliary, the raw materials are as follows: 70 parts of water, X-405 Alkylphenol 0.1 part of polyoxyethylene wetting agent, 1 part of ethylene glycol, 0.1 part of BIT fungicide, 9 parts of airgel, 0.65 part of lauryl alcohol film-forming aid, the B component includes cement inorganic coagulant, S18 glass beads, anti-cracking fiber, low-temperature anti-cracking clay, filler 200 mica powder, water-retaining methyl cellulose and cement dispersant superplasticizer, the raw materials are as follows: cement inorganic coagulant 64 parts, S18 glass microspheres 13 0.2 parts of anti-cracking fiber, 4 parts of low-temperature anti-cracking clay, 14 p...

Embodiment 2

[0030] An anti-shedding thermal insulation material, including component A and component B, its raw materials are as follows: the component A is 0.8 parts, the component B is 1.0 parts, and the component A includes water, X -405 Alkylphenol Polyoxyethylene Wetting Agent, Ethylene Glycol, BIT Bactericide, Airgel and Lauryl Fatty Film-forming Auxiliary, the raw materials are as follows: 72.5 parts of water, X-405 Alkylphenol 0.1 part of polyoxyethylene wetting agent, 2 parts of ethylene glycol, 0.2 part of BIT fungicide, 10 parts of airgel, 0.75 part of dodecyl alcohol film-forming aid, the B component includes cement inorganic coagulant, S18 glass beads, anti-cracking fiber, low-temperature anti-cracking clay, filler 200 mica powder, water-retaining methyl cellulose and cement dispersant superplasticizer, the raw materials are as follows: cement inorganic coagulant 65 parts, S18 glass microspheres 14 0.3 parts of anti-cracking fiber, 5 parts of low-temperature anti-cracking cla...

Embodiment 3

[0040] An anti-shedding thermal insulation material, including component A and component B, its raw materials are as follows: the component A is 0.8 parts, the component B is 1.0 parts, and the component A includes water, X -405 Alkylphenol polyoxyethylene wetting agent, ethylene glycol, BIT fungicide, aerogel and dodecyl alcohol film-forming aid, the raw materials are as follows: 75 parts of water, X-405 Alkylphenol 0.3 parts of polyoxyethylene wetting agent, 3 parts of ethylene glycol, 0.3 parts of BIT fungicides, 11 parts of airgel, 0.85 parts of lauryl fat film-forming aid, and the B component includes cement inorganic coagulant, S18 glass microspheres, anti-cracking fiber, low-temperature anti-cracking clay, filler 200 mica powder, water-retaining methyl cellulose and cement dispersant superplasticizer, the raw materials are as follows: cement inorganic coagulant 66 parts, S18 glass microspheres 15 parts 0.4 parts of anti-cracking fiber, 6 parts of low-temperature anti-cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com