Fluorosilicone rubber composition, preparation method therefor and sealants and coating materials prepared from composition

A technology of fluorosilicone rubber and composition, applied in the field of fluorosilicone rubber, can solve the problems of polluted air, complicated operation, increased oil resistance effect, etc., and achieve the effects of excellent mechanical properties, oil resistance and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

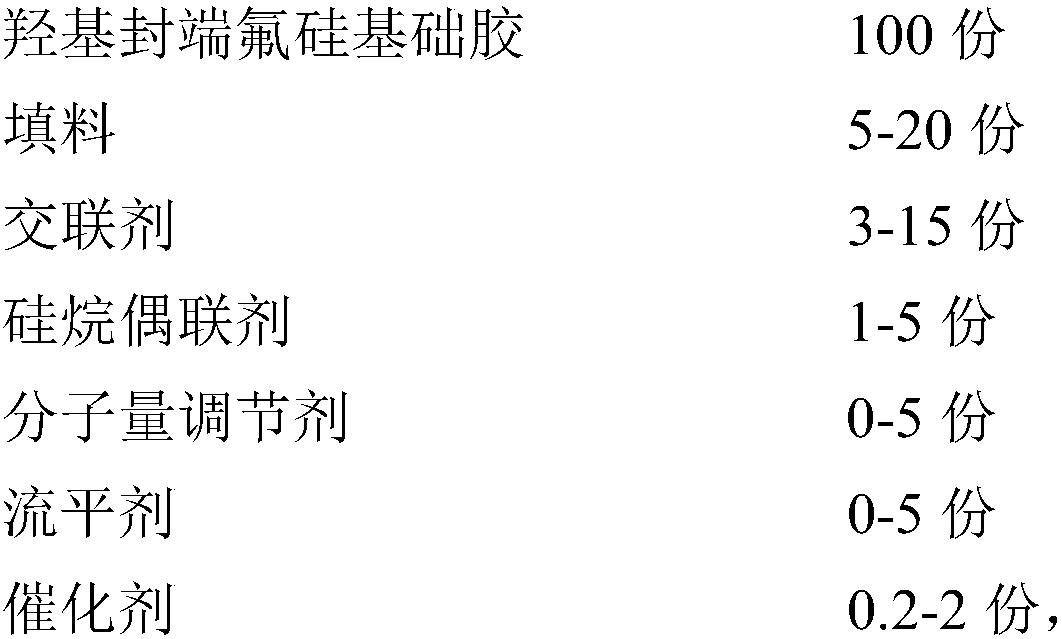

[0039] According to some preferred embodiments of the present invention, the hydroxyl-terminated fluorosilicone base rubber has the following structural formula:

[0040]

[0041] Among them, R 1 =-(CH 2 ) 2 (CF 2 ) p1 CF 3 , p1 is an integer of 0-7, preferably, the p1 is 0 or 3;

[0042] R 2 = Me, Et or Ph, preferably Me;

[0043] m 1 is an integer between 100 and 1000, preferably 200-750, more preferably 300-600, n 1 It is an integer between 0 and 500, preferably 0-300.

[0044] Preferably, the hydroxyl-terminated fluorosilicone base rubber has a viscosity of 5000mpa.s to 90000mpa.s, more preferably 20000mpa.s to 90000mpa.s.

[0045] According to other preferred embodiments of the present invention, the filler comprises fluorine-containing silane-modified white carbon black.

[0046] Preferably, the filler further includes one or more selected from titanium dioxide, silicon micropowder, and calcium carbonate.

[0047] The size of the filler is nanoscale. Nano...

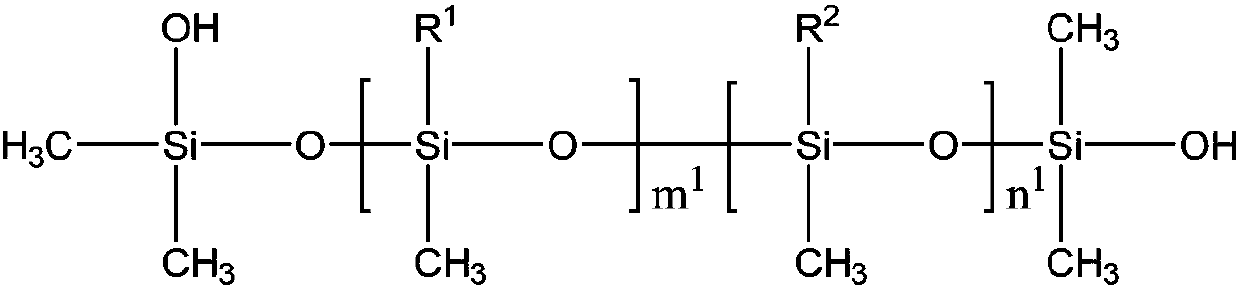

example 1

[0080] Under the protection of nitrogen, add 400g of hydroxyl-terminated fluorosilicone base rubber with a viscosity of 90000mpa.s into the planetary mixer, add 24g of modified white carbon black and 40g of nano-calcium carbonate, and start the planetary mixer. After stirring evenly, add 15g of molecular weight modifier. Stir evenly, then heat up the planetary mixer to 120° C., and stir for 3 hours at a vacuum of 50 Pa. Circulating water was introduced, the temperature was lowered to 60° C., and under the protection of nitrogen, 12 g of di-tert-butoxydiacetoxysilane, 30 g of methyltriacetoxysilane and 4 g of dibutyltin diacetate were added. Mix and stir until smooth. Stand still for 1 hour to obtain RTV-01.

[0081] The hydroxyl-terminated fluorosilicone base glue used is:

[0082]

[0083] Among them, R 1 =-(CH 2 ) 2 (CF 2 ) p1 CF 3 , p1 is 0, R 2 = methyl, m 1 700-750, n 1 is 0.

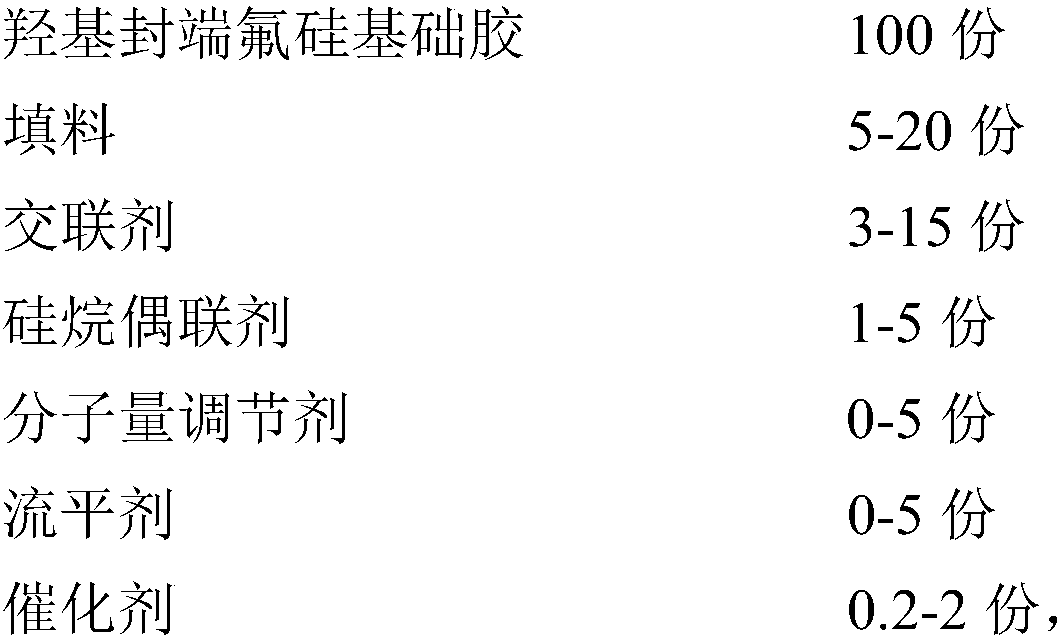

example 2

[0085] Under the protection of nitrogen, add 400g of hydroxyl-terminated fluorosilicone base rubber with a viscosity of 65000mpa.s into the planetary mixer, add 12g of modified white carbon black and 30g of silicon micropowder, and start the planetary mixer. After stirring evenly, add 18g leveling agent. Stir evenly, then heat up the planetary mixer to 130° C., and stir for 2 hours at a vacuum of 50 Pa. Circulating water was introduced, the temperature was lowered to 60° C., and under the protection of nitrogen, 15 g of di-tert-butoxydiacetoxysilane, 30 g of methylethyltriacetoxysilane and 2 g of dibutyltin diacetate were added. Mix and stir until smooth. Stand still for 1 hour to obtain RTV-02.

[0086] The hydroxyl-terminated fluorosilicone base glue used is:

[0087]

[0088] Among them, R 1 =-(CH 2 ) 2 (CF 2 ) p1 CF 3 , p1 is 3, R 2 = methyl, m 1 240-260, n 1 is 0.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com