Method for preparing liquid-metal-based anisotropic conductive adhesive

A liquid metal, anisotropic technology, used in conductive adhesives, adhesives, epoxy resins, etc., can solve problems such as poor mechanical properties, poor flexibility, and limited applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

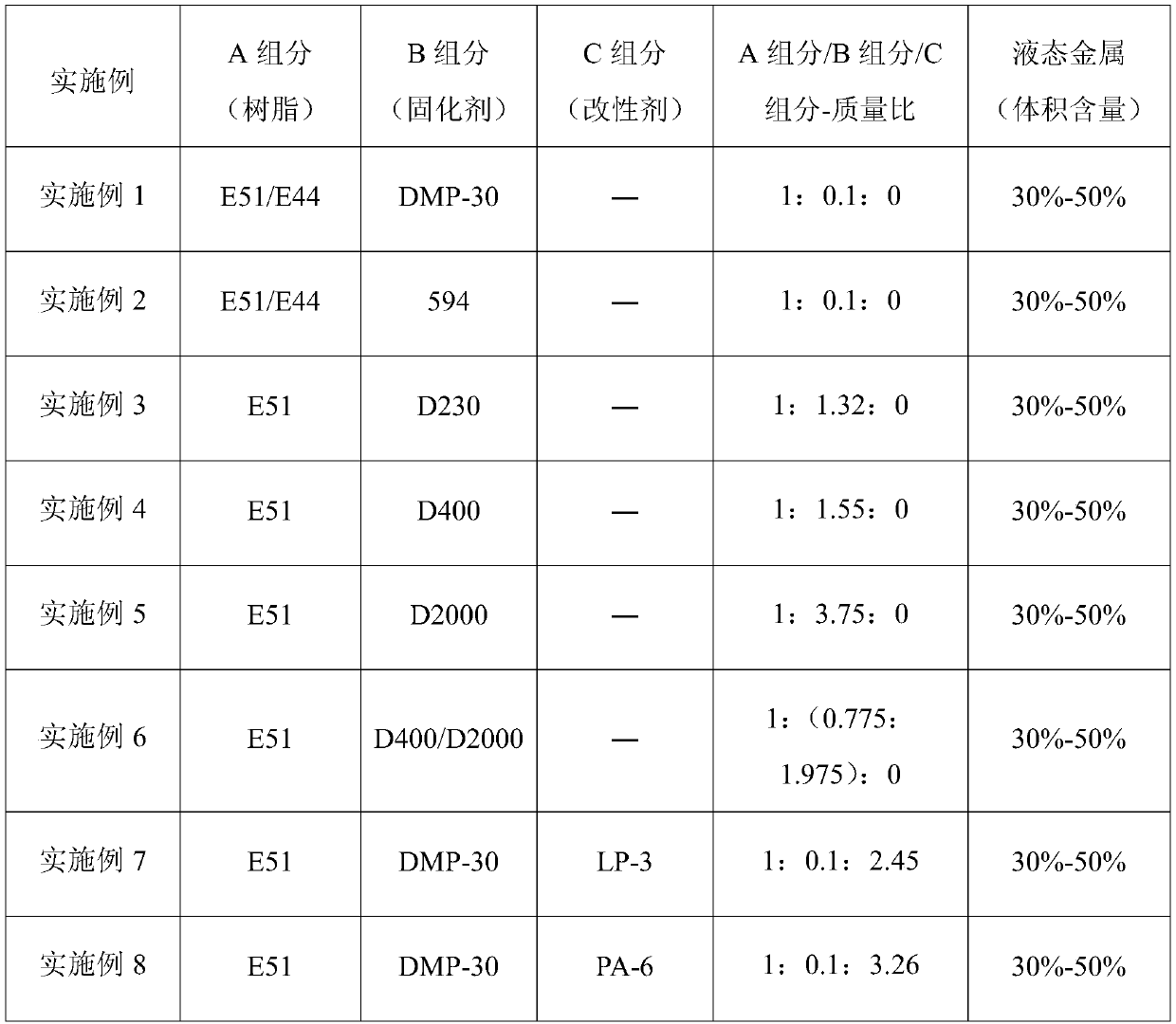

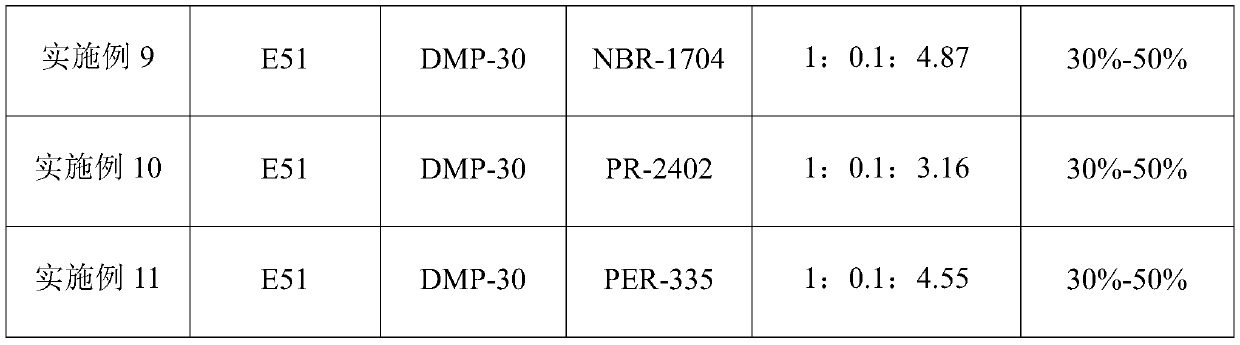

[0025] A kind of preparation method of the anisotropic conductive adhesive based on liquid metal of the present invention can be realized through the following technical solutions:

[0026] Step (1) Preparation of liquid metal anisotropic conductive adhesive: the adhesive used in the present invention can be divided into single-component adhesive and multi-component adhesive, and liquid metal is dispersed in the adhesive (solvent can be used or not) to obtain liquid metal particles The mixture with the adhesive, remove the air bubbles, and store for later use;

[0027] Step (2) How to use liquid metal anisotropic conductive adhesive: Apply the mixture of liquid metal particles and adhesive that removes air bubbles to the substrate (such as traditional circuit board, flexible circuit board, etc.), and then place another substrate on the mixture , forming a sandwich sandwich structure. Curing and molding to obtain liquid metal conductive adhesive. Set the temperature according...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com