Method for extracting lipoxygenase from soybean whey waste water through inverse pH gradient

A technology of soybean whey wastewater and lipoxygenase, which is applied in the direction of oxidoreductase, can solve the problems of large-scale production and application, such as difficult breakthroughs and high costs, and achieve resource recycling, low cost, and high purity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] A method for extracting lipoxygenase from soybean whey wastewater against a pH gradient, comprising the steps of:

[0065] 1) Pretreatment of soybean whey wastewater

[0066] Take 1000mL soybean whey wastewater, centrifuge at 12000r / min for 10min, and keep the supernatant as soybean whey wastewater pretreatment liquid for use in experiments;

[0067] 2) Removal of impurity proteins in soybean whey wastewater pretreatment liquid

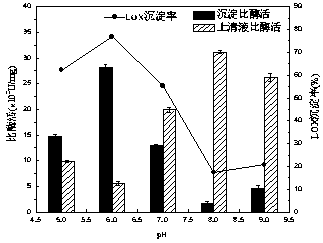

[0068] Using sodium hydroxide solution to adjust the pH of the soybean whey wastewater pretreatment solution to 8.0, and centrifuging to remove the precipitate;

[0069] 3) Extraction of lipoxygenase

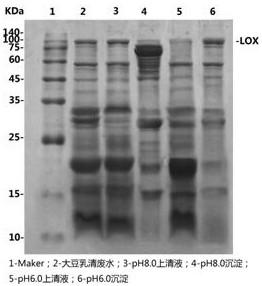

[0070] Use sodium hydroxide solution to adjust the pH value of the supernatant obtained in step 2) to 6.0, remove the supernatant by centrifugation, dissolve the obtained precipitate in distilled water, and adjust the pH to neutral, which is the lipoxygenase crude enzyme solution, measure the enzyme activity and protein content in the crude en...

Embodiment 2

[0085] A method for extracting lipoxygenase from soybean whey wastewater against a pH gradient, comprising the steps of:

[0086] 1) Pretreatment of soybean whey wastewater

[0087] Take 1000mL of soybean whey wastewater, centrifuge at 12000r / min for 10min, and keep the supernatant as soybean whey wastewater pretreatment solution for use in experiments;

[0088] 2) Removal of impurity proteins in soybean whey wastewater pretreatment liquid

[0089] Using sodium hydroxide solution to adjust the pH of the soybean whey wastewater pretreatment solution to 8.0, and centrifuging to remove the precipitate;

[0090] 3) Extraction of lipoxygenase

[0091] Use sodium hydroxide solution to adjust the pH value of the supernatant obtained in step 2) to 6.0, remove the supernatant by centrifugation, dissolve the obtained precipitate in distilled water, and adjust the pH to neutral, which is the lipoxygenase crude enzyme liquid;

[0092] 4) The lipoxygenase crude enzyme solution is purif...

Embodiment 3

[0111] A method for extracting lipoxygenase from soybean whey wastewater against a pH gradient, comprising the steps of:

[0112] 1) Pretreatment of soybean whey wastewater

[0113] Take 1000mL of soybean whey wastewater, centrifuge at 12000r / min for 10min, and keep the supernatant as soybean whey wastewater pretreatment solution for use in experiments;

[0114] 2) Removal of impurity proteins in soybean whey wastewater pretreatment liquid

[0115] Using sodium hydroxide solution to adjust the pH of the soybean whey wastewater pretreatment solution to 8.0, and centrifuging to remove the precipitate;

[0116] 3) Extraction of lipoxygenase

[0117] Use sodium hydroxide solution to adjust the pH value of the supernatant obtained in step 2) to 6.0, remove the supernatant by centrifugation, dissolve the obtained precipitate in distilled water, and adjust the pH to neutral, which is the lipoxygenase crude enzyme liquid;

[0118] 4) Preliminary purification of lipoxygenase crude ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com