Device for non-destructive detection of cigarette holes

A technology of non-destructive testing and holes, which is applied in the direction of measuring devices, optical devices, and optical testing of flaws/defects, etc. It can solve the problems of non-destructive measurement of the size of holes in cigarettes with holes in online tipping paper, and achieves simple structure and automation. High, reproducible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

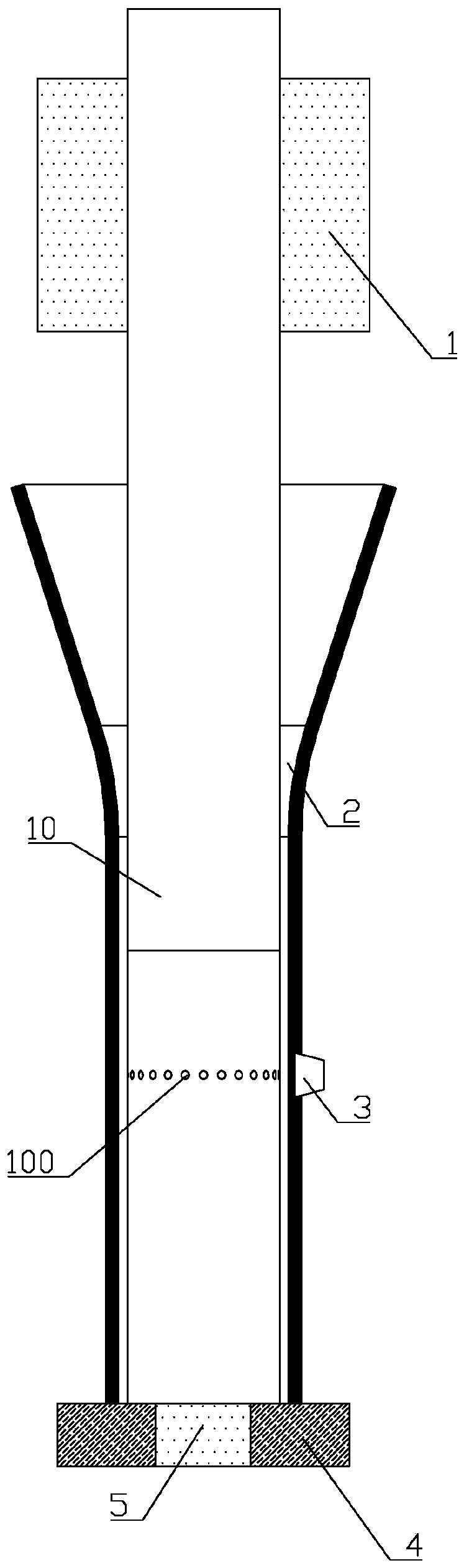

[0037] like figure 1 and Figure 3-Figure 8 As shown, the device for non-destructive testing of cigarette cigarette holes in this embodiment includes a detection system and a data processing system; the detection system includes a rotating holder 1 and an imaging mechanism 3, and the rotating holder 1 is used to clamp and fix the hole to be detected cigarette 10, and drives the cigarette 10 to be detected to rotate.

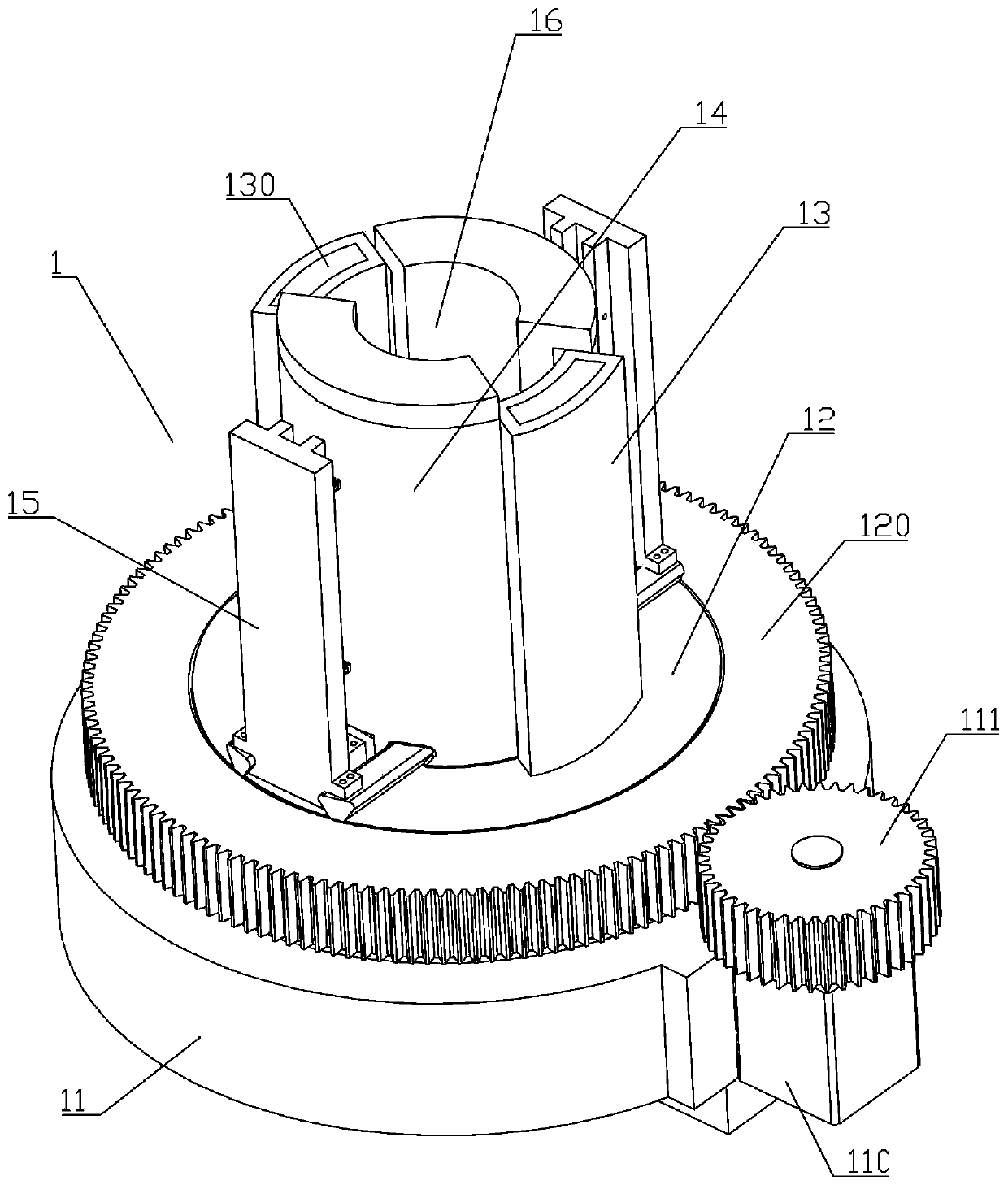

[0038] Specifically, the rotating clamper 1 includes a base 11, a rotating base 12 is installed for rotation in the base 11, an outer ring gear 120 is fixedly installed on the rotating base 12, a rotating motor 110 is installed on the outer wall of the base 11, and the power of the rotating motor 110 A gear 111 is fixedly installed on the output shaft, the gear 111 meshes with the outer ring gear 120, a through hole 121 is opened on the rotating base 12, and two installation sleeves 13 are uniformly arranged around the through hole 121 on the upper end surface o...

Embodiment 2

[0050] The differences between this embodiment and Embodiment 1 are:

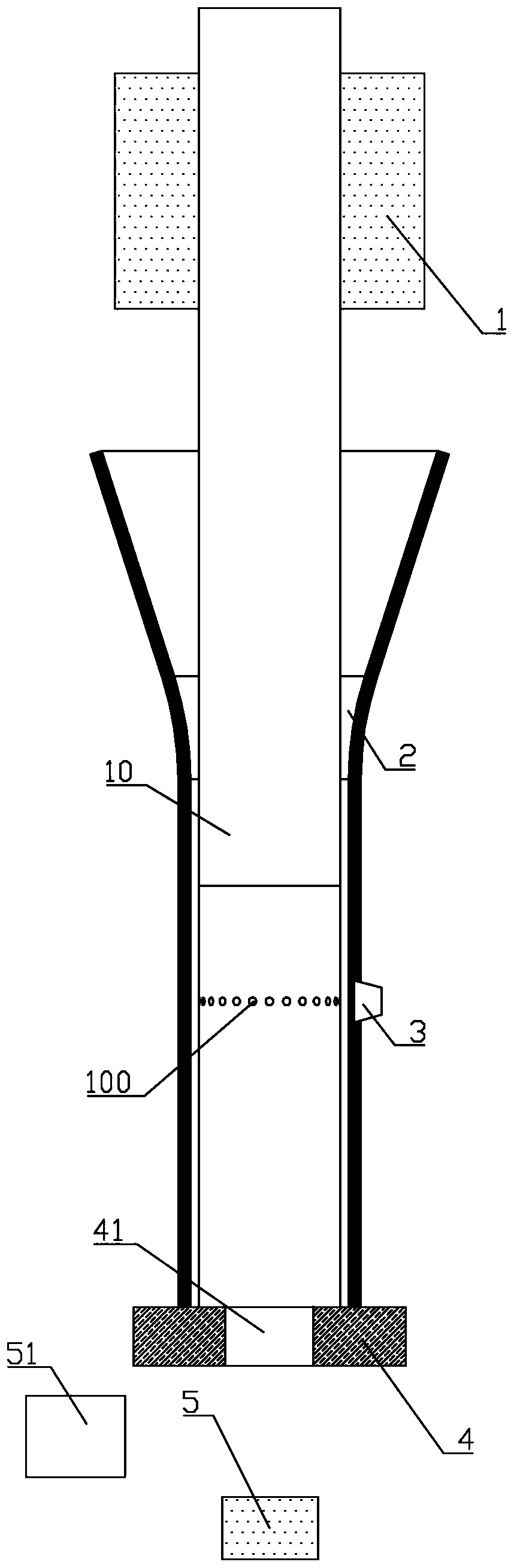

[0051] Such as figure 2 As shown, the light source 5 is located below the movable chassis 4, and the trajectory of the movable chassis 4 is to move up and down. The distance between the light source 5 and the movable chassis 4 is not less than the length of the cigarette stick 10. There is also a horizontal pushing mechanism 51 between the light source 5, specifically, the horizontal pushing mechanism 51 can be pushed horizontally by an air cylinder, which has a simple structure and is easy to operate.

[0052] With such a structural design, after the cigarette holder 1 is rotated to loosen the cigarette holder 10, the movable chassis 4 does not move to one side, but moves downward, so that the cigarette holder 10 can be dropped from the sleeve 2 for reuse. The lateral pushing mechanism 51 pushes away the cigarettes in the sleeve 2, and then the movable chassis 4 is reset, so that the next round of cigare...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com