Apparatus for optimizing wide-range image collection based on machine vision and detection method thereof

A machine vision and optimization device technology, applied in measuring devices, image enhancement, image analysis, etc., can solve problems such as large error range, fixed error, easy to cover defects, etc., and achieve the effect of improving image uniformity and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

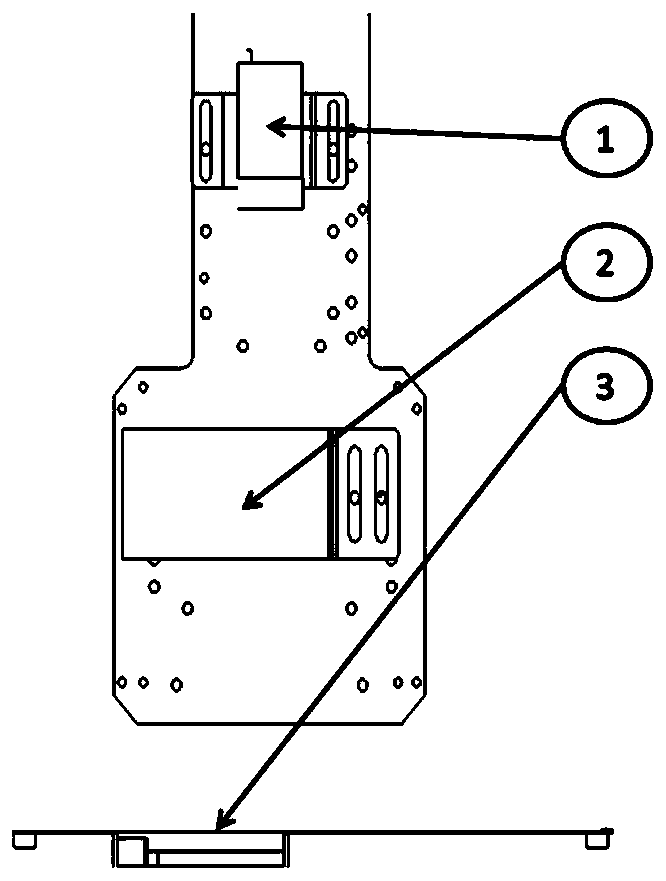

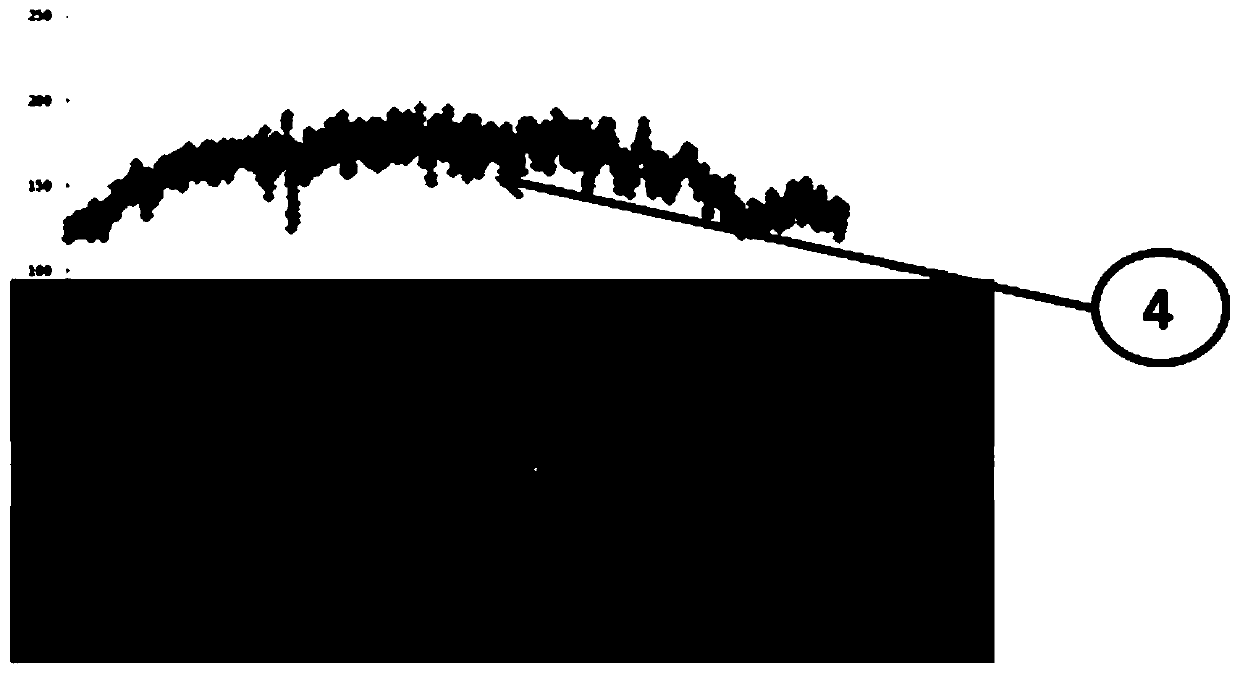

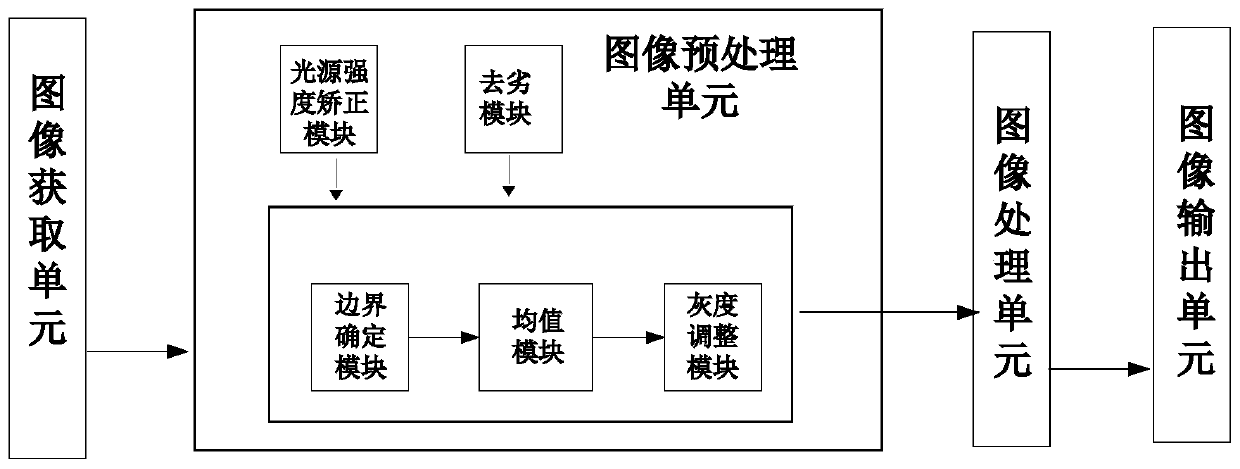

[0037] Attached below Figure 3-9 , the specific embodiment of the present invention will be further described in detail.

[0038] It should be noted that the present invention is an application of a machine vision system. The same as other machine vision systems, the machine vision of the present invention uses machines instead of human eyes to make measurements and judgments, and converts the ingested objects into images through machine vision products (ie, image acquisition units, which are divided into CMOS and CCD) The signal is sent to a dedicated image processing unit to obtain the morphological information of the photographed target, which is converted into a digital signal according to the pixel distribution, brightness, color and other information; the image processing unit can perform various operations on these signals to extract the characteristics of the target, Furthermore, according to the result of discrimination, it is output by the output unit to control th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com