Chain equipment for crystalline silicon texturing and preparation method for single-sided inverted pyramid texturing

A kind of equipment and chain technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of increasing the manufacturing process and cost of solar cells, increasing the difficulty of back throwing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

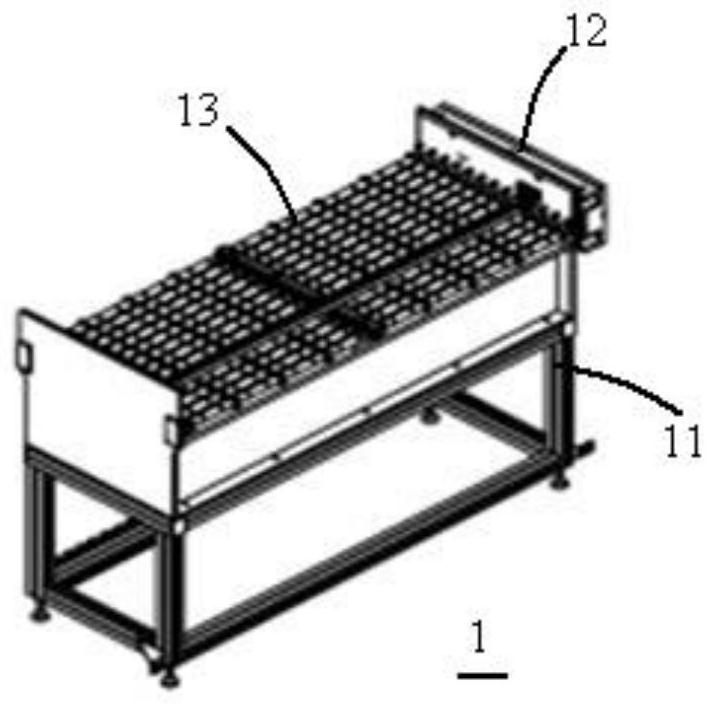

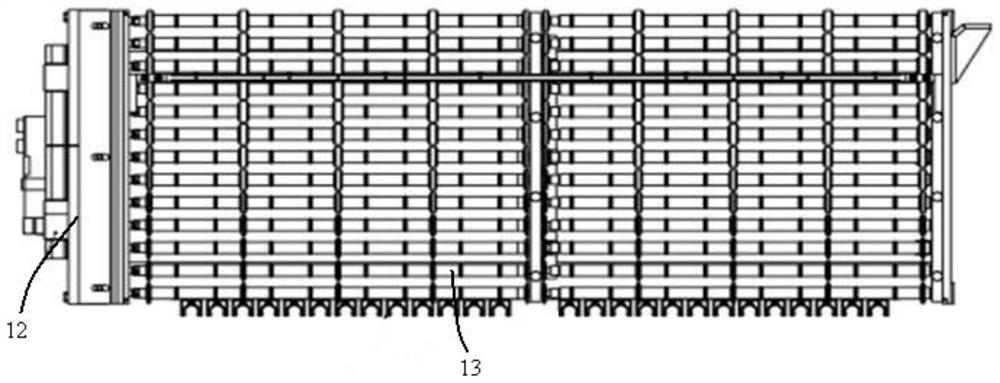

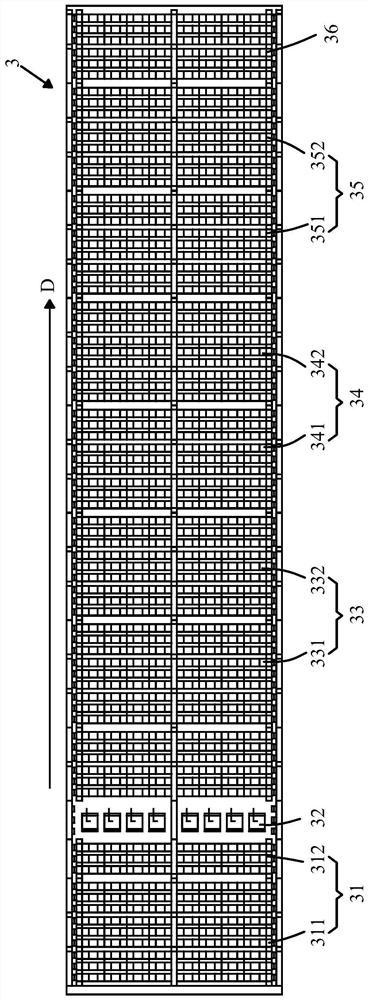

[0038] image 3 is a top view of a chain device according to a preferred embodiment of the present invention, wherein image 3 The same chain drive system as in prior art chain equipment is not shown. Such as image 3 As shown, the chain equipment 3 includes a texturing tank 31, a chipping device 32, a metal removal tank 33, and a back polishing tank arranged in sequence along the direction indicated by the arrow D (that is, the moving direction of the crystal silicon on the texturing process line). Tank 34, cleaning tank 35 and drying tank 36.

[0039] Texture-making tank 31, slicer 32, metal removal tank 33, back polishing tank 34, cleaning tank 35 and drying tank 36 are all made of acid and alkali-resistant materials for use in v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com