Kitchen waste processor high overload brushless DC motor driving system and method

A technology for brushing DC motors and kitchen waste, used in AC motor control, control systems, control generators, etc., can solve problems such as inability to deal with internal odors, high overload coefficients, etc., and achieve low cost, low power density, and small size. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

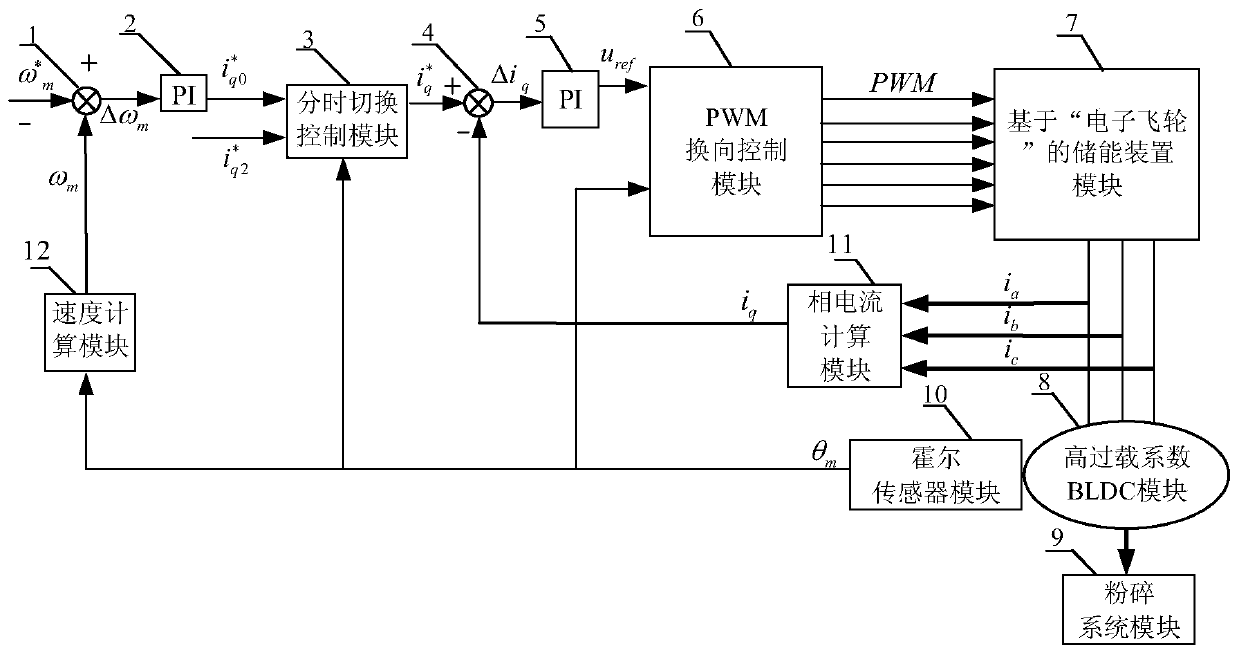

[0053] Embodiment 1, kitchen garbage processor high overload brushless DC motor drive system, such as figure 1 As shown, it includes a first subtractor 1, a PI regulator module 2, a time-sharing switching control module 3, a second subtractor 4, a PI regulator module 5, a PWM commutation control module 6, and an energy storage device module based on an electronic flywheel 7. High overload coefficient BLDC module 8, crushing system module 9, Hall sensor module 10, phase current calculation module 11 and speed calculation module 12.

[0054] The upper computer system will set the speed ω * m Input into the first subtractor 1.

[0055] The first subtractor 1 according to the given speed ω * m and actual speed ω m , the error value Δω of the speed is obtained by calculation m , and the speed error value Δω m Input to PI regulator block 2.

[0056] PI regulator module 2 according to the input speed error value Δω m , the closed-loop given quadrature axis current is obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com