Piezoelectric acoustic wave filter

A piezoelectric sound wave and filter technology, applied in the direction of electric solid devices, circuits, electrical components, etc., can solve the problems affecting the out-of-band suppression of the filter, and achieve the effect of height reduction and small inductance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

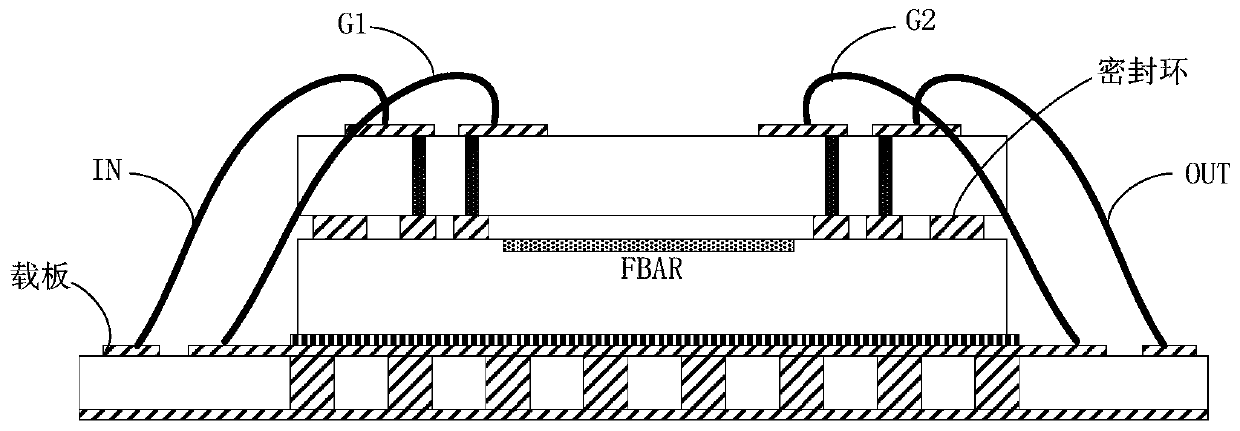

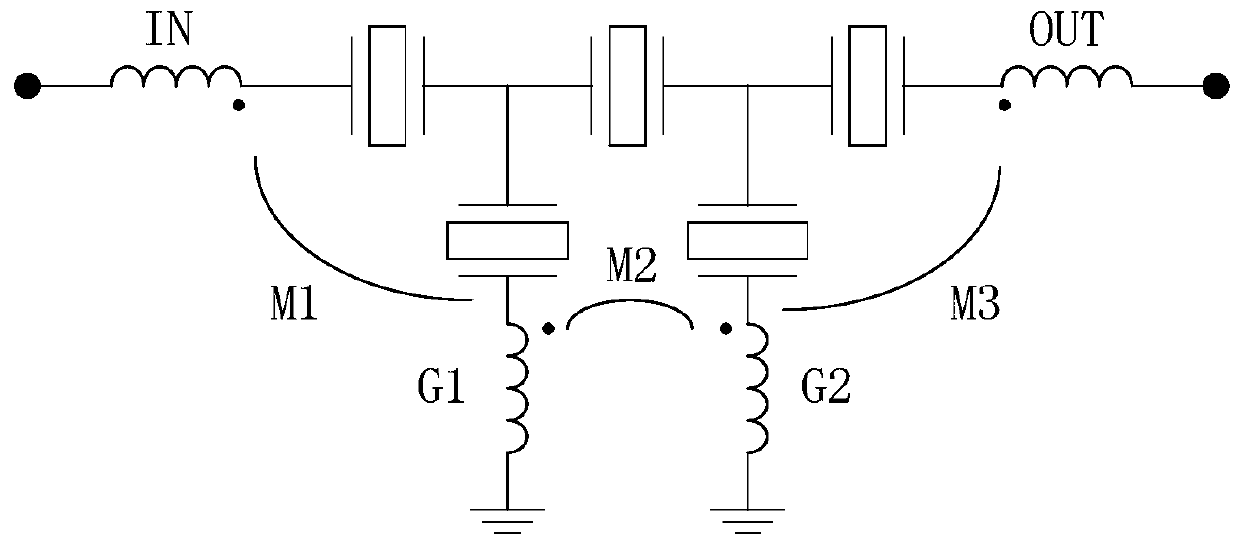

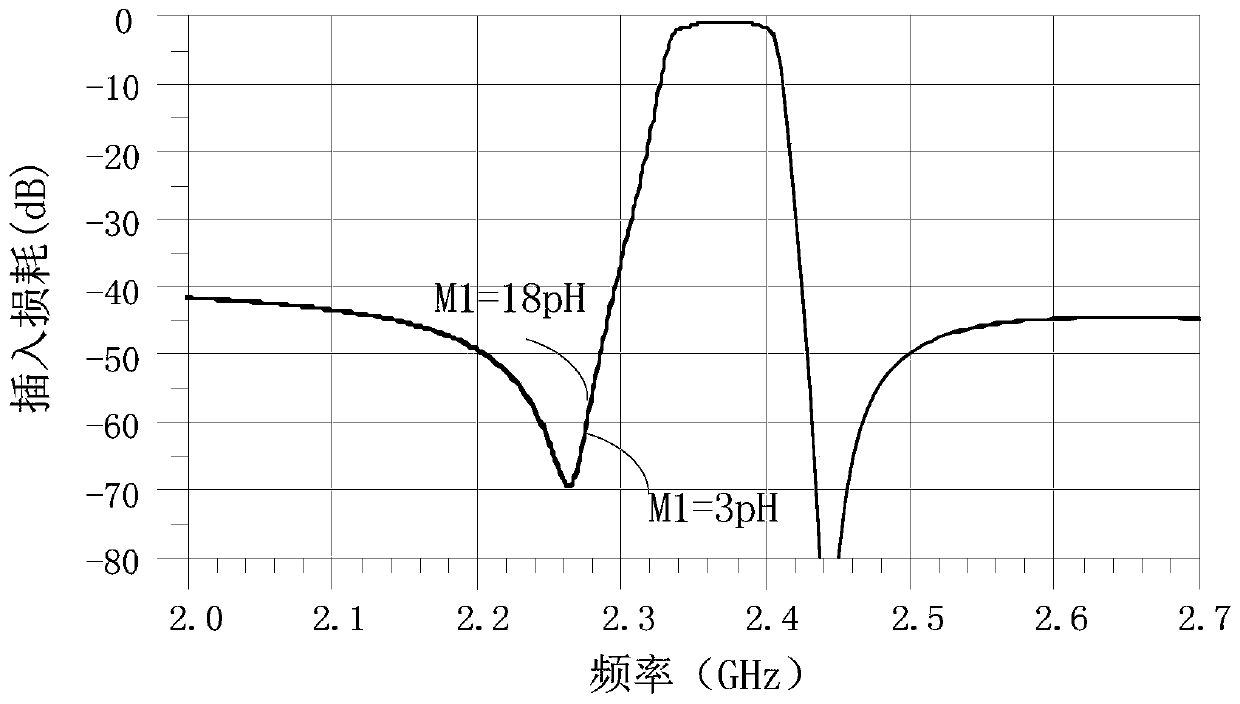

[0031] Figure 4a and 4b It is a structural diagram of the implementation of a piezoelectric acoustic wave filter, Figure 4b The two signals of IN and OUT in the middle are connected to the series resonator, and are conducted to the bonding pad on the upper surface of the upper wafer through the via hole of the upper wafer. The bonding pad or transmission line on the board; the two grounds of G1 and G2 are connected to the parallel resonator, and are connected to the metallization plane on the lower surface of the lower wafer through the via hole of the lower wafer. Such as Figure 4a and 4b As shown, the piezoelectric acoustic wave filter includes a carrier board 1 and a chip on the carrier board 1 consisting of an upper wafer 4 and a lower wafer 5, and an input signal bonding pad is arranged on the upper surface of the upper wafer 4 Chip 3 and output signal bonding gasket 11, input signal bonding finger 2 and output signal bonding finger 12 are arranged on the carrier boa...

Embodiment 2

[0038] Figure 5 It is the structural diagram of the second piezoelectric acoustic wave filter in this implementation. Such as Figure 5 As shown, the piezoelectric acoustic wave filter includes a carrier board 1 and a chip on the carrier board 1 consisting of an upper wafer 4 and a lower wafer 5, and an input signal bonding pad is arranged on the upper surface of the upper wafer 4 Chip 3 and output signal bonding gasket 11, input signal bonding finger 2 and output signal bonding finger 12 are arranged on the carrier board 1; a sealing ring 7 is arranged between the upper wafer 4 and the lower wafer 5 for Enclose sensitive circuits between two wafers.

[0039] The upper wafer 4 is provided with two via holes 10, and the lower wafer 5 is also provided with two via holes 10; the input signal line is connected to the upper surface of the upper wafer through a via hole in the upper wafer 4 The input signal bonding pad 3; the output signal lines are respectively connected to the...

Embodiment 3

[0045] Figure 6a and 6b is the structural diagram of the implementation of the triple piezoelectric acoustic wave filter, where Figure 6b The dotted box indicates the contour edge on the wafer. Such as Figure 6a and 6b As shown, the piezoelectric acoustic wave filter includes a carrier plate 1 and an upper wafer 4 and a lower wafer 5 arranged from top to bottom on the carrier plate 1, and the upper wafer 4 and the lower wafer 5 are provided with The sealing ring 7 is used to seal the sensitive circuit between two wafers; the upper surface of the lower wafer 5 is provided with an input signal bonding pad 3 and an output signal bonding pad 11, and the carrier board 1 An input signal bonding finger 2 and an output signal bonding finger 12 are provided.

[0046] The lower wafer 5 is provided with two via holes 10; the sealing ring 7 is provided with an opening, and the input signal line passes through the opening on the sealing ring and is connected to the input signal bon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com