Method for preparing SmCo5/Sm2Co17 core-shell dual-phase composite magnetic nanoparticles in situ

A technology of core-shell structure and composite magnetism, which is applied in the direction of nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve the problem that the SmCo magnetic phase phase shell cannot be coated

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

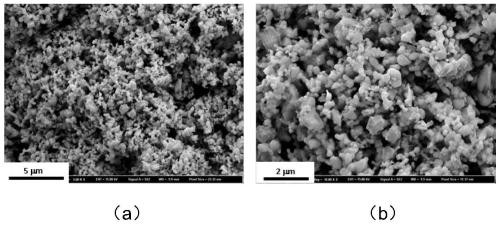

Image

Examples

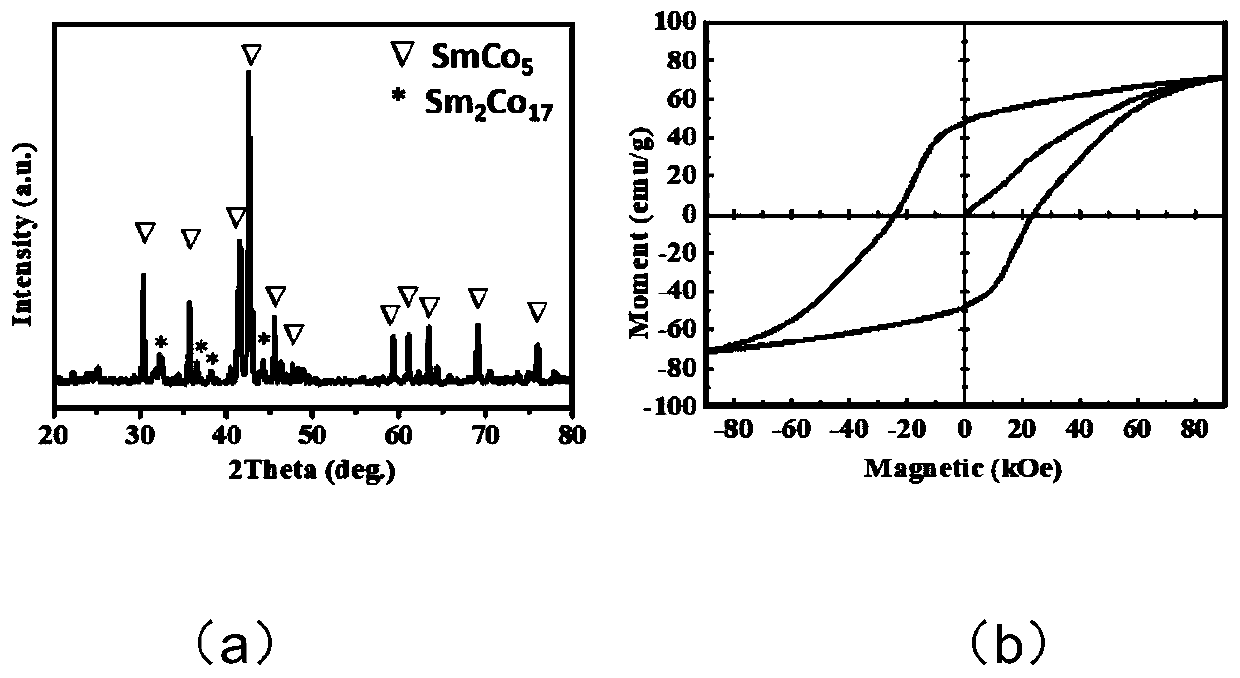

Embodiment 1

[0033] S1. Preparation of precursor SmCoCa-OH.

[0034] 1) Take a 250mL three-necked flask and place it in an ultrasonic water bath, and add SmCl with a purity of more than 99% to the three-necked flask 3 ·6H 2 O powder 0.54g, CoCl with a purity of 99.99% or more 2 ·6H 2 O powder 1.35g, CaCl with a purity of more than 99% 2 1.15g of particles, then add 100mL of deionized water into the three-necked flask, and start the mechanical stirring. After 10 minutes, turn on the ultrasonic instrument, and add 15 mL of 3.5 mol / L NaOH solution into the three-neck flask.

[0035] 2) After reacting for 1 hour, add 100-150 mL of deionized water to the reaction solution to dilute the solution, then transfer the solution to a centrifuge tube, centrifuge at a speed of 5000-8000 rpm for 3-5 minutes, pour off the supernatant and keep Precipitate in a centrifuge tube; add deionized water to the centrifuge tube, ultrasonically clean for 5 minutes, centrifuge at a speed of 5000-8000 rpm for 3-5...

Embodiment 2

[0043] S1. Preparation of precursor SmCoCa-OH.

[0044] 1) Take a 250mL three-necked flask and place it in an ultrasonic water bath, and add SmCl with a purity of more than 99% to the three-necked flask 3 ·6H 2 O powder 0.54g, CoCl with a purity of 99.99% or more 2 ·6H 2 O powder 1.35g, CaCl with a purity of more than 99% 2 1.54g of particles, then add 100mL of deionized water into the three-neck flask, and start the mechanical stirring. After 10 minutes, turn on the ultrasonic instrument, and add 18 mL of 3.5 mol / L NaOH solution into the three-necked flask.

[0045] 2) After reacting for 1 hour, add 100-150 mL of deionized water to the reaction liquid to dilute the solution, then transfer the solution to a centrifuge tube, centrifuge at a speed of 5000-8000 rpm for 3-5 minutes, pour off the supernatant and keep Precipitate in the centrifuge tube; add deionized water to the centrifuge tube, ultrasonically clean for 5 minutes, centrifuge at a speed of 5000-8000 rpm for 3-5...

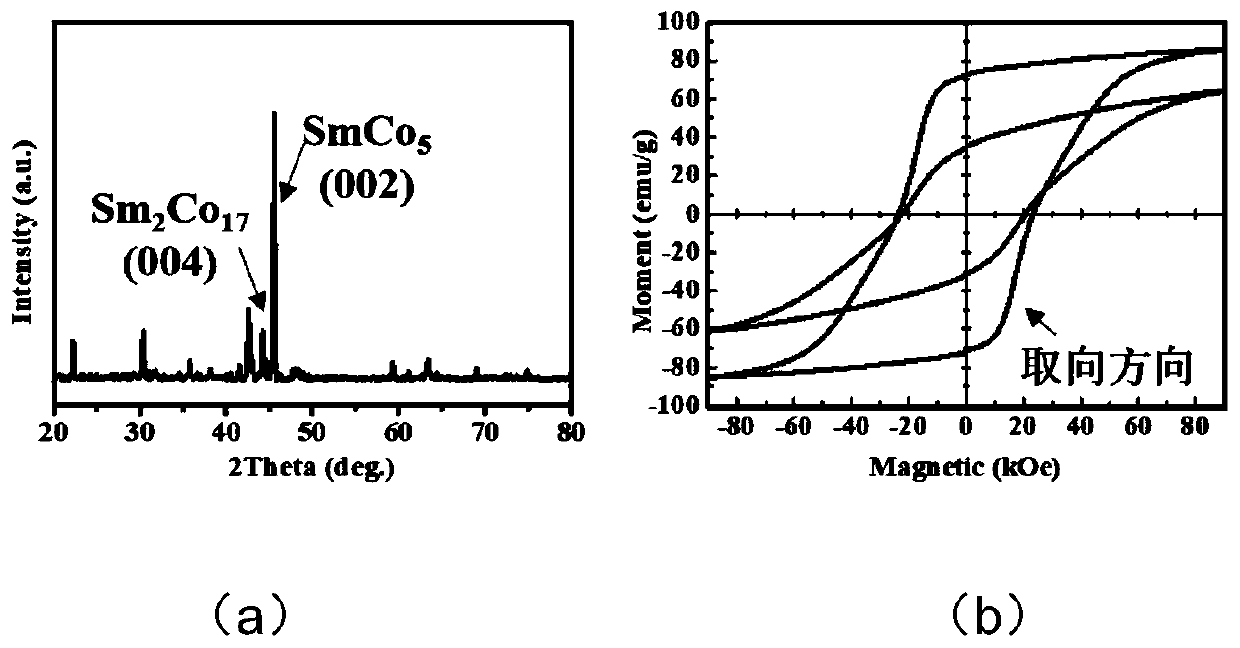

Embodiment 3

[0050] S1. Preparation of precursor SmCoCa-OH.

[0051] 1) Take a 250mL three-necked flask and place it in an ultrasonic water bath, and add SmCl with a purity of more than 99% to the three-necked flask 3 ·6H 2 O powder 0.54g, CoCl with a purity of 99.99% or more 2 ·6H 2 O powder 1.35g, CaCl with a purity of more than 99% 2 2.31g of particles, then add 100mL of deionized water into the three-necked flask, and start the mechanical stirring. After 10 minutes, turn on the ultrasonic instrument, and add 24 mL of 3.5 mol / L NaOH solution into the three-necked flask.

[0052] 2) After reacting for 1 hour, add 100-150mL deionized water to the reaction liquid to dilute the solution, then transfer the solution to a centrifuge tube, centrifuge at a speed of 5000-8000 rpm for 3-5 minutes, pour off the supernatant and keep Precipitate in the centrifuge tube; add deionized water to the centrifuge tube, ultrasonically clean for 5 minutes, centrifuge at a speed of 5000-8000 rpm for 3-5 m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Coercivity | aaaaa | aaaaa |

| Residual magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com