High-temperature-resistant special water-retaining admixture for concrete as well as preparation process and application of admixture

A technology of high temperature resistance and admixture, applied in the field of concrete admixture, can solve the problems of sensitivity, affecting pumping effect, accelerating concrete evaporation, etc., and achieves the effect of not easy to segregate bleeding and good water locking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0074] Example 1: A special water-retaining admixture for high-temperature resistant concrete, the components included and their corresponding mass content are as shown in Table 1, and are prepared by the following steps:

[0075] Step 1: Mix the sustained-release polycarboxylic acid and the comprehensive polycarboxylic acid for 15 minutes to obtain a first mixture;

[0076] Step 2: Add retarder, biomass glue, and water to the first mixture obtained in Step 1, and mix for 15 minutes to obtain a second mixture;

[0077] Step 3: Add defoamer to the second mixture obtained in Step 2, after mixing for 5 minutes, add the air-entraining agent in parts by weight, and mix for 10 minutes to obtain a water-retaining admixture.

[0078] Among them, the retarder is sodium gluconate; the biomass glue is xanthan gum; the defoamer is a polyether modified silicone defoamer, the model is 878; the air-entraining agent is air-entraining agent AE-2.

[0079] The preparation process of sustained-release pol...

Embodiment 2-7

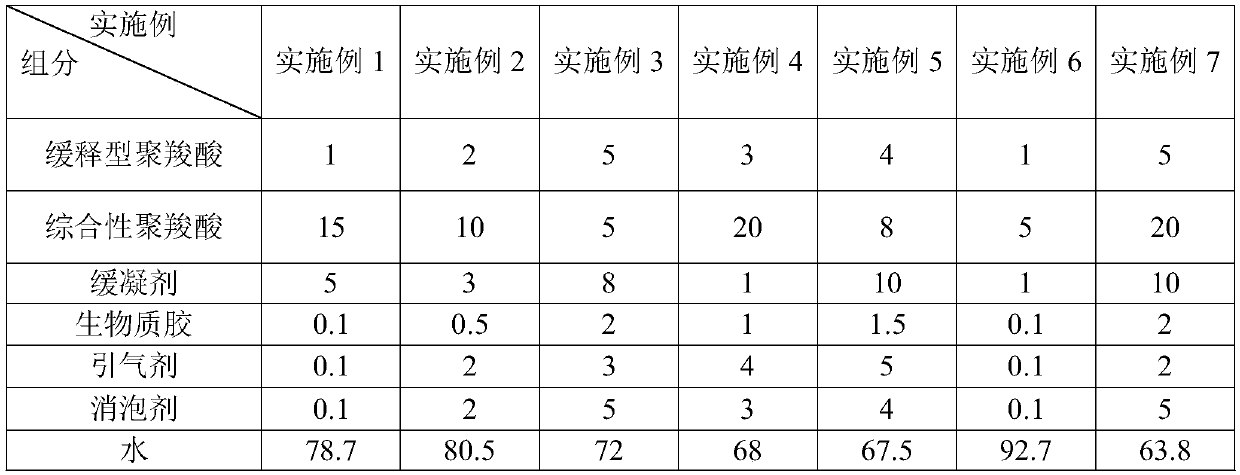

[0089] Example 2-7: A special water-retaining admixture for high temperature resistant concrete. The difference from Example 1 is that the included components and their corresponding qualities are shown in Table 1.

[0090] Table 1 The components included in Examples 1-7 and their corresponding masses (kg)

[0091]

Embodiment 8

[0092] Example 8: A special water-retaining admixture for high-temperature resistant concrete. The difference from Example 1 is that the retarder is molasses and sodium lignosulfonate with a mass ratio of 2.3:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com