Preparation method of pure-nickel valve body casting

A pure nickel casting technology, applied in the field of preparation of pure nickel valve body castings, can solve the problems of low efficiency and high production cost, and achieve the effect of improving production efficiency and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

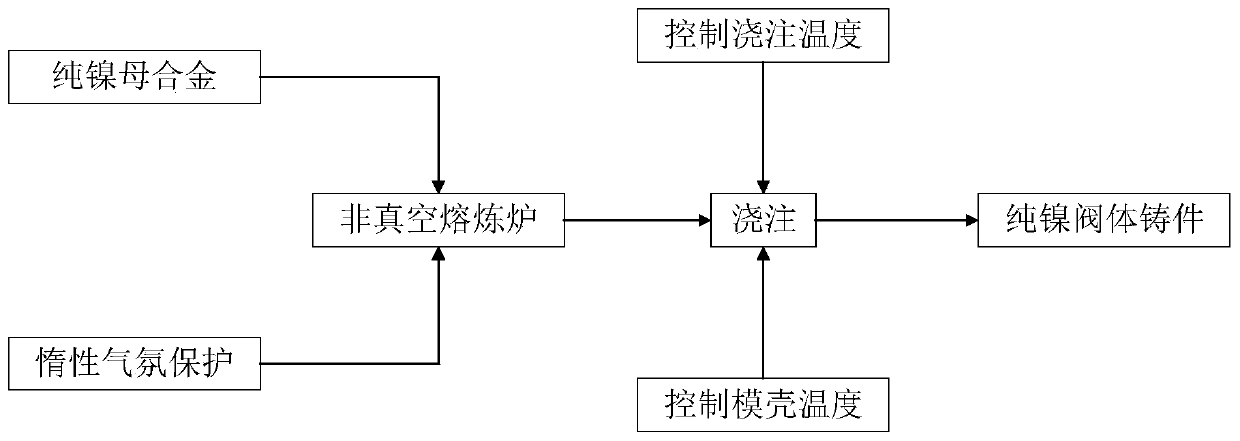

[0049] A kind of preparation method of pure nickel valve body casting, such as figure 1 As shown, it includes the following steps:

[0050]Protect 100kg of pure nickel master alloy with argon gas, and use a 500kW non-vacuum intermediate frequency induction furnace for melting under non-vacuum conditions to obtain molten steel. The smelting temperature is 1530° C. to 1560° C., the smelting is 50 minutes, and the liquid surface of the molten steel is covered with a covering agent, and the height of the covering agent on the surface of the molten steel is 10 mm. When the temperature of the molten steel reaches 1530-1540°C, deoxidation treatment is carried out. First add deoxidizer Ti (purity greater than 99%, dosage is 0.05% of the total mass of molten steel) to the molten steel, and deoxidize for 2 minutes; then add deoxidizer Al (purity greater than 99%, consumption is 0.05% of the total mass of molten steel), deoxidation 1min; finally add deoxidizer Ni-Mg alloy (the content o...

Embodiment 2

[0052] A preparation method of pure nickel valve body casting, it comprises the steps:

[0053] Protect 100kg of pure nickel master alloy with argon gas, and use a 500kW non-vacuum intermediate frequency induction furnace for melting under non-vacuum conditions to obtain molten steel. The smelting temperature is 1530° C. to 1560° C., smelting for 50 minutes, and the liquid surface of the molten steel is covered with a covering agent, and the height of the covering agent on the surface of the molten steel is 11 mm. When the temperature of molten steel reaches 1530-1540°C, deoxidation treatment is carried out, first add deoxidizer Ti (purity greater than 99%, dosage is 0.1% of the total mass of molten steel) to molten steel, and deoxidize for 2 minutes; then add deoxidizer Al (purity greater than 99%, the consumption is 0.1% of the total mass of molten steel), deoxidation 1min; finally add deoxidizer Ni-Mg alloy (the content of Mg is 20% of the total mass of deoxidizer Ni-Mg all...

Embodiment 3

[0055] A preparation method of pure nickel valve body casting, it comprises the steps:

[0056] Protect 100kg of pure nickel master alloy with argon gas, and use a 500kW non-vacuum intermediate frequency induction furnace for melting under non-vacuum conditions to obtain molten steel. The smelting temperature is 1530° C. to 1560° C., smelting for 50 minutes, and the liquid surface of the molten steel is covered with a covering agent, and the height of the covering agent on the surface of the molten steel is 12 mm. When the temperature of molten steel reaches 1530-1540°C, deoxidation treatment is carried out. First add deoxidizer Ti (purity greater than 99%, dosage is 0.08% of the total mass of molten steel) to the molten steel, and deoxidize for 2 minutes; then add deoxidizer Al (purity greater than 99%, the consumption is 0.08% of the total mass of molten steel), deoxidation 1min; finally add deoxidizer Ni-Mg alloy (the content of Mg is 20% of the total mass of deoxidizer Ni-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap