Integrated system and method for raw recycled aggregate drying equipment

A technology for recycled aggregates and drying equipment, applied in roads, road repairs, roads, etc., can solve problems such as cost of construction, high maintenance cost, high operating cost, high cost of burners and furnaces, and low service life of furnaces, etc., to achieve reduction Equipment and maintenance costs, improved energy efficiency, and low equipment costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below through specific embodiments.

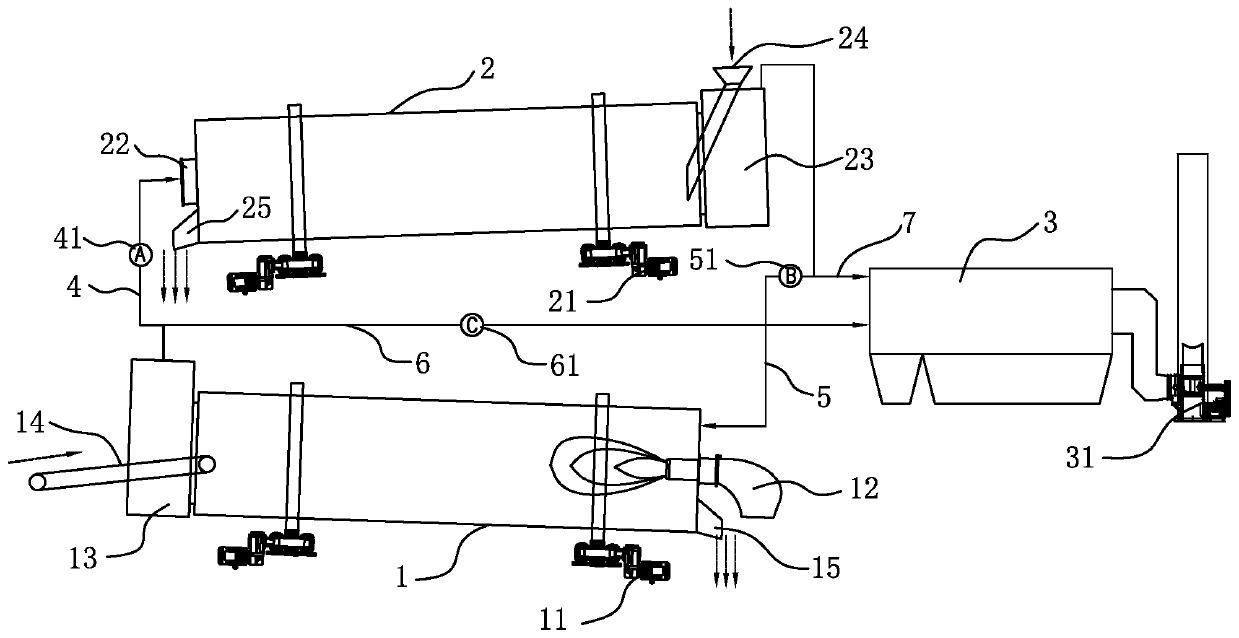

[0022] refer to figure 1 As shown, an integrated system of raw recycled aggregate drying equipment includes a raw raw material drying drum 1 , a recycled raw material drying drum 2 , and a dust collector 3 .

[0023] The raw material drying drum 1 is driven and rotated by the first frequency conversion motor 11. The two ends of the raw material drying drum 1 are respectively provided with a burner 12 and a first induced air box 13. The raw material drying drum 1 is also provided with a raw material The raw material inlet 14, the raw material outlet 15, the raw material inlet 14 is located at one end of the first induced air box 13, the raw material outlet 15 is located at the burner 12 end, and the raw material drying drum 1 is heated by countercurrent heat exchange Raw materials; the regenerated material drying drum 2 is driven to rotate by the second frequency conversion motor 21, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com