Steel casing type deep sea vibroflotation pile construction method

A construction method and technology of steel casing, applied in soil protection, infrastructure engineering, construction, etc., can solve the problem of underwater cleaning and sand backfilling, which are easily scoured by seawater, difficult to reinforce underwater foundation, and marine environment pollution, etc. problems, achieve high engineering significance and application prospects, reduce equipment and material investment, and improve the effect of foundation strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

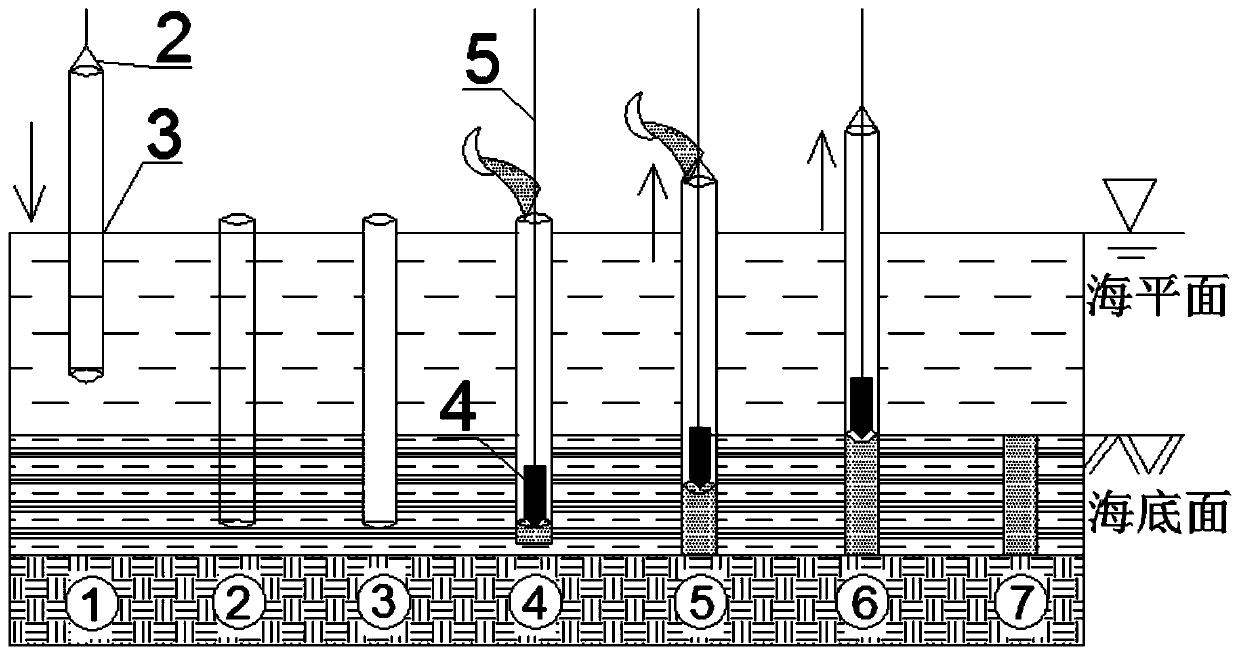

[0015] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] A kind of construction method of steel casing type deep sea vibrating pile of the present invention comprises the following steps:

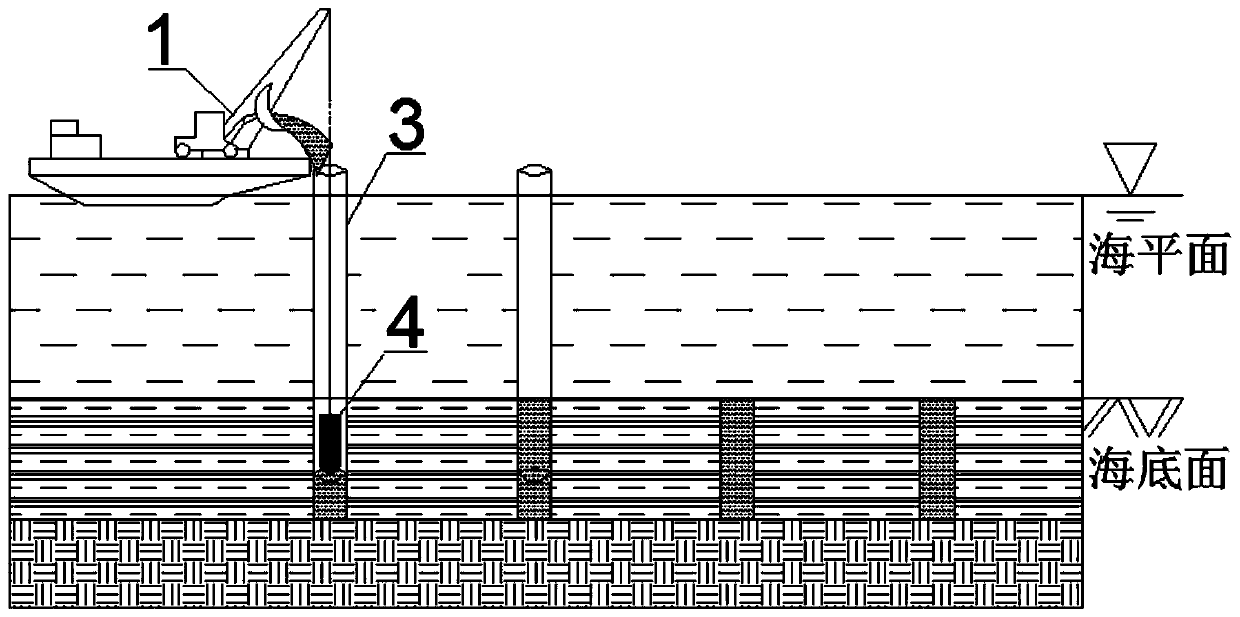

[0017] (1) The top of the steel casing 3 is connected to the first cable 2, and the steel casing 3 is inserted into the design depth below the seabed at the set pile position (the steel casing can sink into the bottom of the sea by virtue of its own weight, or it can be installed on The piling machine on the floating crane 1 is driven below the seabed surface), the inclination of the main shaft installed on the steel casing is not more than 1%, and the floating crane 1 returns to its original position after being separated from the first cable 2; see figure 2 Steps ① and ② in the above; the design depth shall be determined according to the actual soil conditions, and the steel casing shall be ensured to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com