Control logic verification platform for million-capacity-grade turbine island

A technology of control logic and verification platform, applied in general control systems, control/regulation systems, instruments, etc., can solve the problems that control logic cannot automatically execute sequential control steps, cannot verify the correctness of control logic, and cannot get feedback on instructions. , to achieve the effect of saving time and energy, high degree of automation and good control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

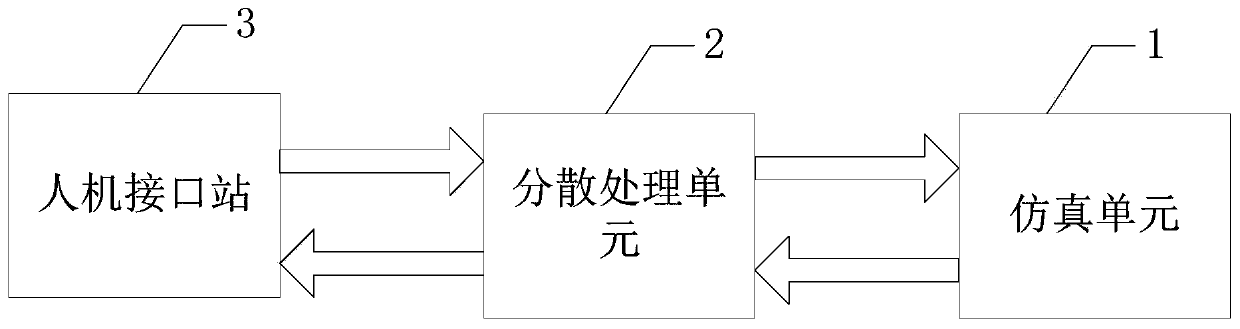

[0017] Specific implementation mode one: refer to figure 1 This embodiment is specifically described. The million-capacity steam turbine island control logic verification platform described in this embodiment includes a simulation unit 1, a distributed processing unit 2, and a human-machine interface station 3.

[0018] The simulation unit 1 is used to construct the simulation model of the steam turbine auxiliary system and the steam turbine main body, receive the control signal sent by the distributed processing unit 2, execute the control instructions on the steam turbine auxiliary system simulation model and the steam turbine main body simulation model, and transfer the steam turbine auxiliary system simulation model to the current The state information of the state information and the state information of the steam turbine body simulation model are fed back to the distributed processing unit 2;

[0019] The decentralized processing unit 2 is used to receive the control sig...

specific Embodiment approach 2

[0024] Specific embodiment 2: This embodiment is to further explain the million-capacity steam turbine island control logic verification platform described in specific embodiment 1. In this embodiment, the steam turbine auxiliary control system includes a lubricating oil system, an anti-fuel system, a shaft Sealing system, turbine body drainage system, turbine body extraction system, turbine low pressure cylinder water spray system, high exhaust ventilation valve and high exhaust check valve.

specific Embodiment approach 3

[0025] Embodiment 3: This embodiment is to further explain the million-capacity steam turbine island control logic verification platform described in Embodiment 1. In this embodiment, it also includes a communication unit,

[0026] The simulation unit and the distributed processing unit are connected through a communication unit.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com