Grabbing device and transfer mechanism

A technology for grabbing devices and installing components, which is applied in packaging, paper product packaging, transportation and packaging, etc. It can solve the problems of inability to absorb non-woven fabric masks, unsatisfactory separation effects and unsatisfactory results of material extraction, etc., to achieve Reduce the probability of secondary pollution, improve the flexibility of picking and placing, and the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

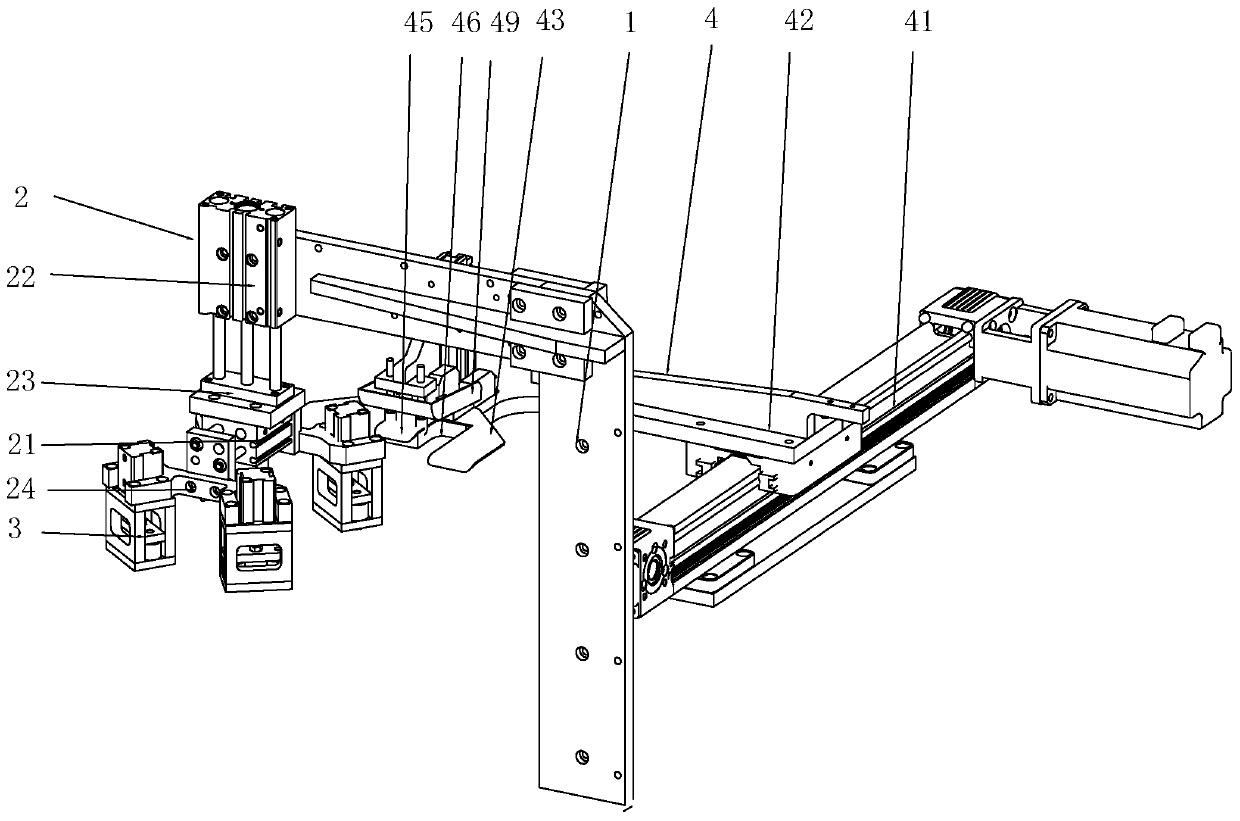

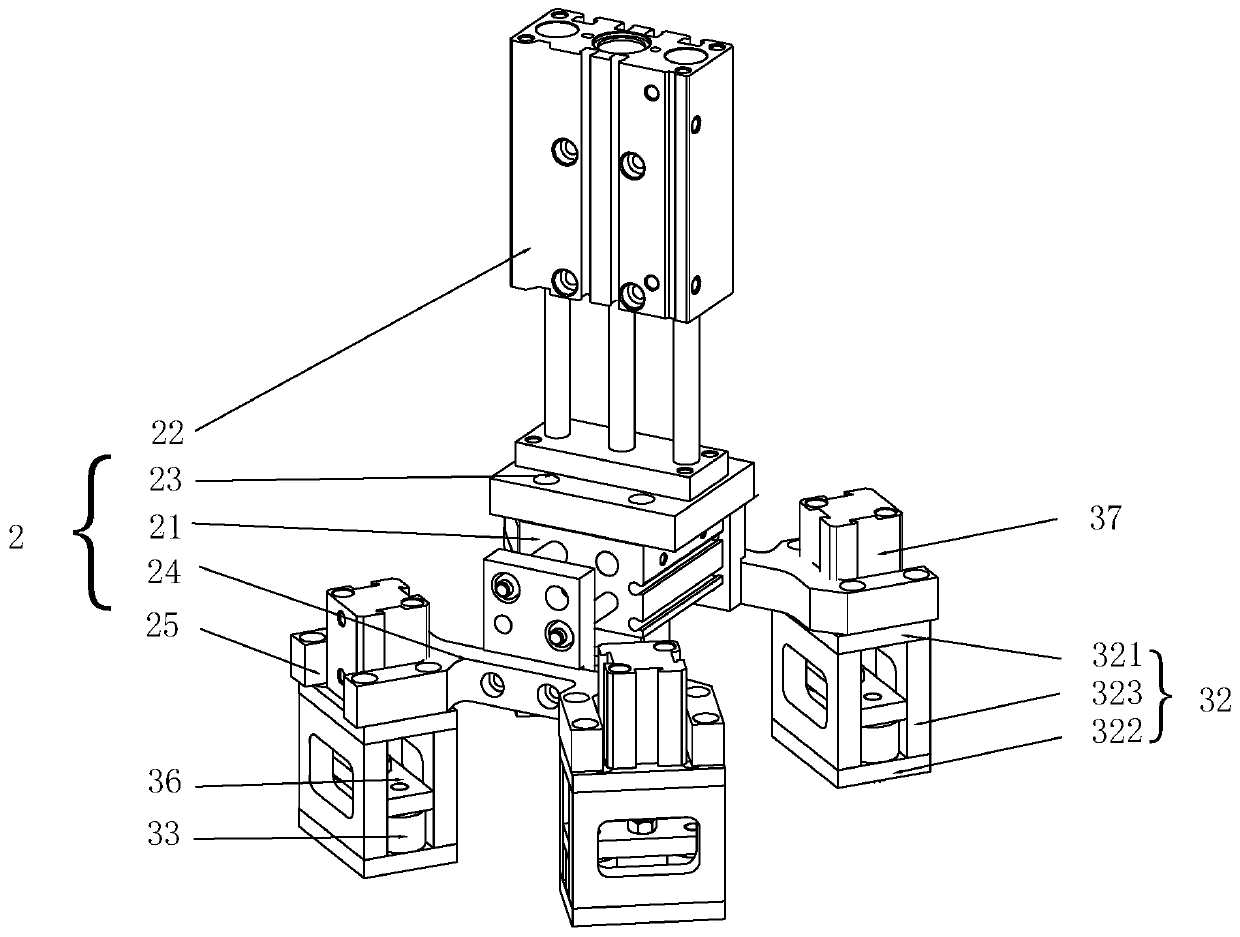

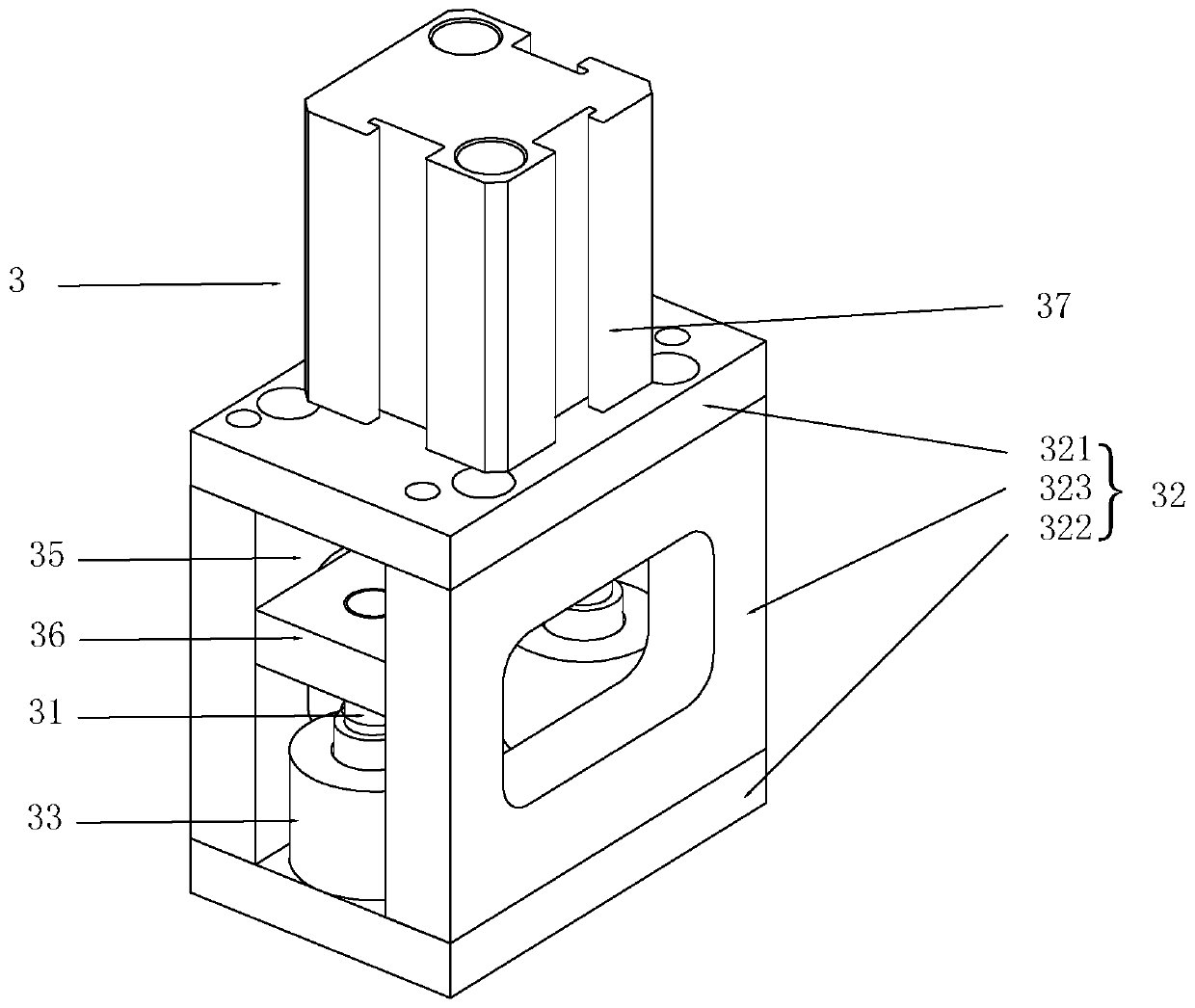

[0028] see Figure 1 to Figure 8 , a grabbing device of the present invention, comprising: a mounting member 1, a rubbing assembly 2, a rubbing assembly 2 and a retrieving assembly 3; wherein, the rubbing assembly 2 can be lifted and mounted on the mounting member 1, and there At least two groups of rubbing members 21; the output ends of all rubbing members 21 are arranged on the back, and all can be stretched along the stacking plane direction of workpiece stacking; Component 31; wherein, all the rubbing components 2 can drive the corresponding pick-up component 31 to stretch and bring up the workpiece. Of course, the main function of the rubbing component 21 is to rub the workpiece by driving the pick-up component 31, so that the workpiece is stacked on the top In addition to the workpiece being able to be separated from other workpieces, the pick-up member 31 can be driven to move outward through the joint cooperation of multiple rubbing members 21, and then the pick-up mem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com