Method for preparing graphene by combining germanium concentration and ion implantation technology

A technology of ion implantation and graphene, which is applied in the direction of graphene, semiconductor/solid-state device manufacturing, electrical components, etc., can solve problems such as damage and fracture, influence of device preparation, impurity defects and pollution, so as to reduce loss and avoid secondary transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

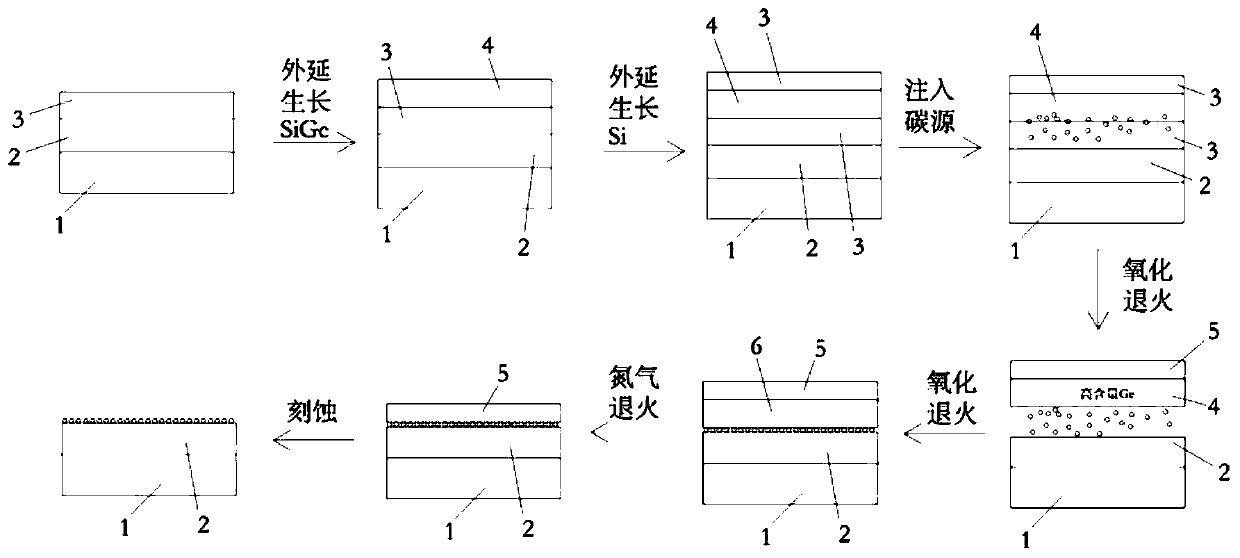

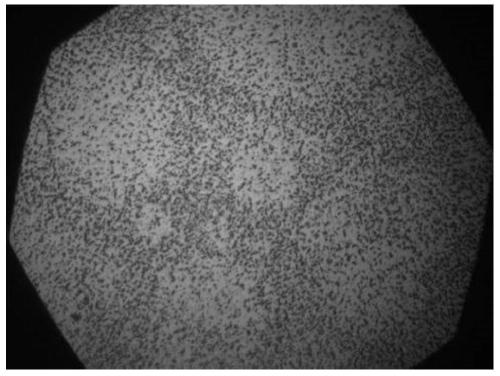

[0030] see Figure 1-2 , what this embodiment provides is a kind of method that combines germanium concentration and ion implantation technology to prepare graphene, comprises the following steps:

[0031] Step ①: Provide SOI substrate, which includes Si substrate layer 1 (Si sub, 30nm), SiO 2 Substrate layer 2 (300nm) and Si layer 3 (30nm), SiGe composite layer 4 (75nm) is chemically vapor deposited on the surface of Si layer 3, SiGe composite layer 4 is composed of Ge simple substance and Si simple substance, wherein Ge simple substance accounts for SiGe composite layer 4 30% of the total mass is affected by the simple substance Si, and the melting point of the simple substance Ge in the SiGe composite layer 4 is increased;

[0032] Step ②: use chemical vapor deposition to epitaxially grow a layer of Si layer 3 (4nm) on the surface of the SiGe composite layer 4 away from the SOI substrate again, so that the SiGe composite layer 4 is locked between the two Si layers 3, so as...

Embodiment 2

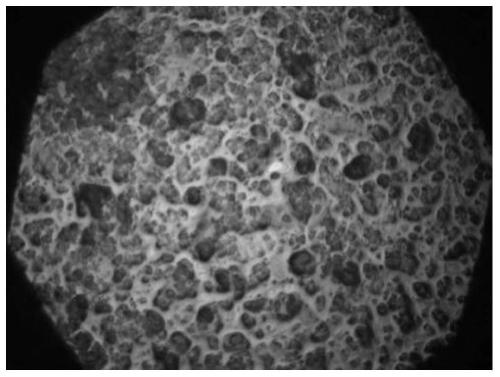

[0048] see image 3 , The difference between this embodiment and Embodiment 1 is that in step ①, the thickness of the Si layer of the SOI substrate is 100 nm, and it can be seen that although graphene is grown, it is very uneven. The main reason may be that during the annealing process, the SiGe composite layer and SiO 2 The increase in the distance between the substrate layers increases the movement distance of the carbon ions in the middle of the SiGe composite layer to the edge of the SiGe composite layer, so the corresponding carbon ions move to the SiO 2 After the substrate layer is more uneven, the growth of graphene is more uneven. At the same time, due to the early SiO 2 The substrate layer acts as a barrier to carbon ions, so carbon ions will be unevenly distributed in the Si layer before annealing and heating, resulting in differences in the growth base points of graphene at different positions.

Embodiment 3

[0050] see Figure 4 , The difference between this embodiment and Embodiment 1 is that in step ①, Ge simple substance accounts for 50% of the total mass of the SiGe composite layer. It can be seen that graphene is still growing, and the growth rate of graphene has been greatly improved due to the increase in the content of Ge element, but because Ge element will be vaporized during the annealing process in nitrogen environment, but due to the SiO 2 The shielding effect of the layer, the vaporization position is more intense at the edge of the Ge layer, the greater the content of Ge element, the greater the difference in the growth rate and degree of the corresponding graphene between the edge and the center.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com