Manufacturing method of expansion type heat insulation supporting liner

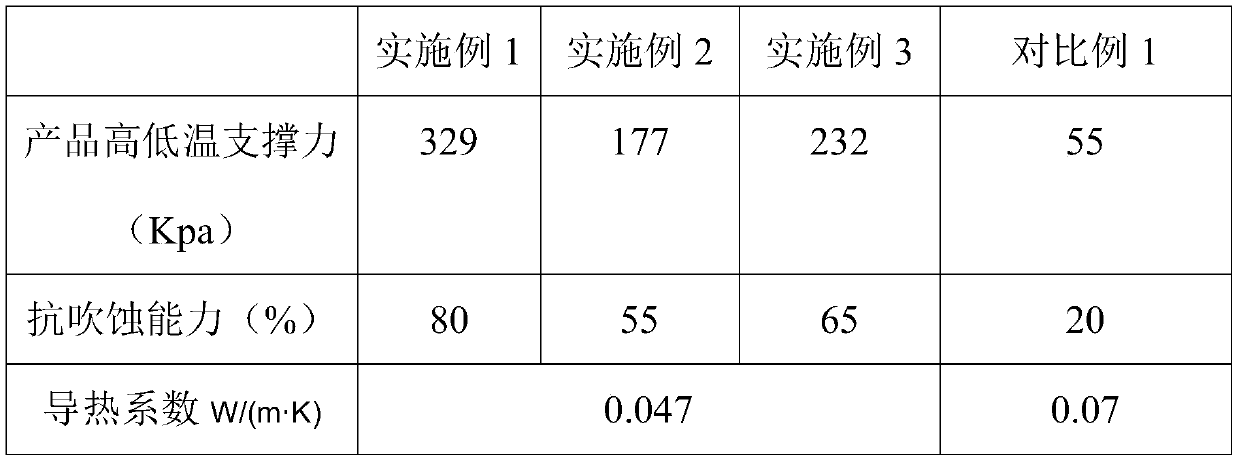

A supporting pad and manufacturing method technology, applied in the direction of manufacturing tools, ceramic molding machines, auxiliary molding equipment, etc., can solve the problems of weak high and low temperature supporting force, lack of gap sealing performance, and unsatisfactory heat insulation effect, etc., to achieve Excellent high and low temperature support performance, strong blowing corrosion resistance, and stable quality per unit area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

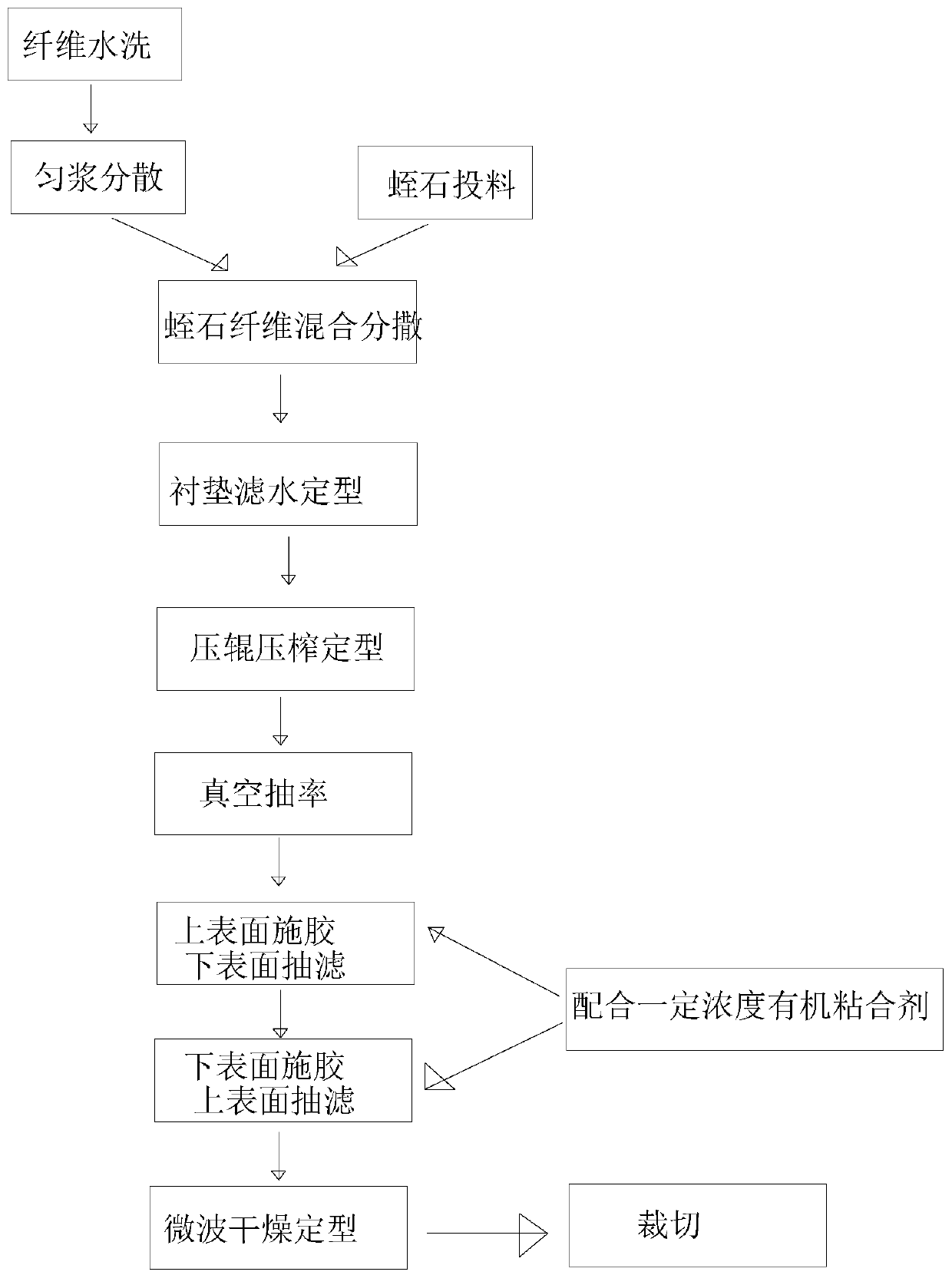

Method used

Image

Examples

Embodiment 1

[0038] (1) Select the aluminum silicate fiber with a temperature resistance above 1260°C formed by blowing or spinning process, the fiber content of the aluminum silicate fiber is 48%, and the fiber is purified by a conical slag remover until the aluminum silicate fiber The shot content of the fiber is 25% (mass percentage), and then water is added to make a fiber slurry with a fiber content of 1%;

[0039] (2) homogenate:

[0040] Using a vermiculite feeding device, add vermiculite to the aluminum silicate fiber slurry, wherein the mass ratio of vermiculite to aluminum silicate fiber is 1:3, and homogenize and disperse the mixed slurry at a homogenization speed of 60r / min , homogenate for 30min;

[0041] (3) The uniformly dispersed fiber vermiculite mixed slurry obtained in step (2) is preliminarily filtered to remove most of the water, and the filter cake is pressed and shaped by the pressure roller of the liner forming box, and vacuum filtration is performed. Sizing treat...

Embodiment 2

[0044] (1) Select the aluminum silicate fiber with a temperature resistance above 1260°C formed by blowing or spinning process, the fiber content of the aluminum silicate fiber is 50%, and the fiber is purified by a conical slag remover until the aluminum silicate fiber The shot content of the fiber is 35% (mass percentage), then adding water to make a fiber slurry with a fiber content of 0.5%;

[0045] (2) homogenate:

[0046] Using a vermiculite feeding device, add vermiculite to the aluminum silicate fiber slurry, wherein the mass ratio of vermiculite to aluminum silicate fiber is 1:1, and homogenize and disperse the mixed slurry at a homogenization speed of 800r / min , homogenate for 5 minutes;

[0047] (3) The uniformly dispersed fiber vermiculite mixed slurry obtained in step (2) is preliminarily filtered to remove most of the water, and the filter cake is pressed and shaped by the pressure roller of the liner forming box, and vacuum filtration is performed. Sizing trea...

Embodiment 3

[0050] (1) Select the aluminum silicate fiber with a temperature resistance above 1260°C formed by blowing or spinning process, the fiber content of the aluminum silicate fiber is 52%, and the fiber is purified by a conical slag remover until the aluminum silicate fiber The shot content of the fiber is 30% (mass percentage), then adding water to make a fiber slurry with a fiber content of 2%;

[0051] (2) homogenate:

[0052] Using a vermiculite feeding device, add vermiculite to the aluminum silicate fiber slurry, wherein the mass ratio of vermiculite to aluminum silicate fiber is 1:2, and homogenize and disperse the mixed slurry at a homogenization speed of 500r / min , homogenate for 15 minutes;

[0053] (3) The uniformly dispersed fiber vermiculite mixed slurry obtained in step (2) is preliminarily filtered to remove most of the water, and the filter cake is pressed and shaped by the pressure roller of the liner forming box, and vacuum filtration is performed. Sizing treat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com