Soft environment-friendly polyvinyl chloride film with self-cleaning properties

A polyvinyl chloride film, self-cleaning technology, applied in the field of PVC calendered film, can solve the problems of easy peeling, poor compatibility, complex process, etc., and achieve the effect of improving hydrophobicity, reducing film surface energy, and low surface energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

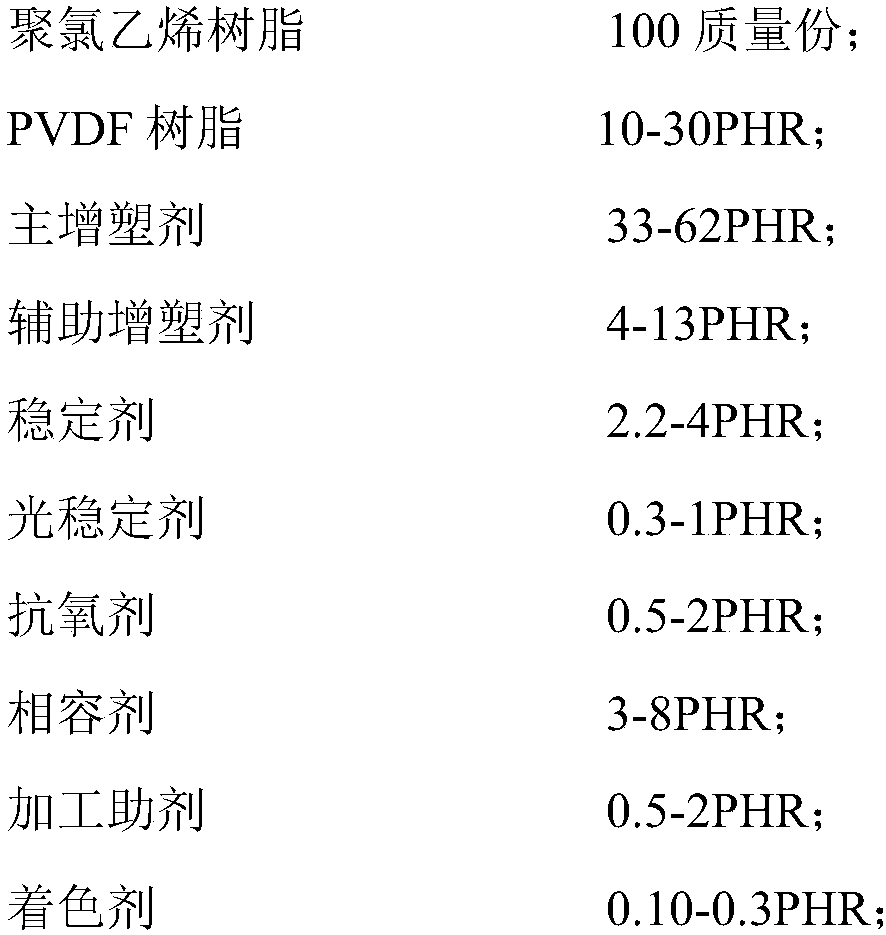

[0030] Raw materials and ratio:

[0031]

[0032]

[0033] Among them, the PVDF resin is the 761 model of the French Arkema company;

[0034] Preparation:

[0035] (1) Kneading material preparation: After measuring polyvinyl chloride resin, PVDF resin, main plasticizer, auxiliary plasticizer, stabilizer, light stabilizer, antioxidant, compatibilizer, processing aid, colorant, Put into a high-speed mixer, perform high-speed mixing in the high-speed mixer, and transfer it to a cooling mixer for cooling after high-speed mixing; wherein, the high-speed mixing termination temperature is 100-150°C; the cold stirring termination temperature is 20-70°C;

[0036] (2) Plasticizing: Feed the mixture obtained in step (1) into a planetary extruder for plasticization; wherein, the temperature in each zone of the planetary extruder is 140-200° C., and the extrusion speed is 40-60 rpm;

[0037] (3) Calendering: Put the fully plasticized material obtained in step (2) into a filter to f...

Embodiment 2

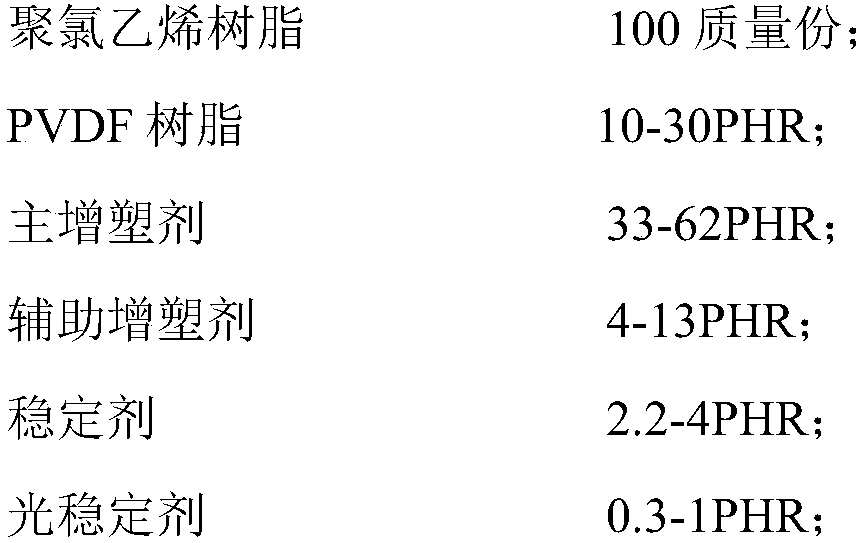

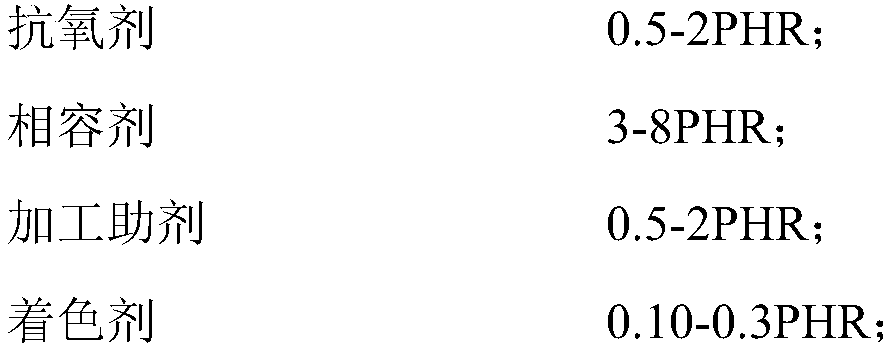

[0042] Raw materials and ratio:

[0043]

[0044]

[0045] Among them, the PVDF resin is the 761 model of the French Arkema company;

[0046] Preparation:

[0047] (1) Kneading material preparation: After measuring polyvinyl chloride resin, PVDF resin, main plasticizer, auxiliary plasticizer, stabilizer, light stabilizer, antioxidant, compatibilizer, processing aid, colorant, Put into a high-speed mixer, perform high-speed mixing in the high-speed mixer, and transfer it to a cooling mixer for cooling after high-speed mixing; wherein, the high-speed mixing termination temperature is 100-150°C; the cold stirring termination temperature is 20-70°C;

[0048] (2) Plasticizing: Feed the mixture obtained in step (1) into a planetary extruder for plasticization; wherein, the temperature in each zone of the planetary extruder is 140-200° C., and the extrusion speed is 40-60 rpm;

[0049](3) Calendering: Put the fully plasticized material obtained in step (2) into a filter to fi...

Embodiment 3

[0054] Raw materials and ratio:

[0055]

[0056]

[0057] Among them, the PVDF resin is the 761 model of the French Arkema company;

[0058] Preparation:

[0059] (1) Kneading material preparation: After measuring polyvinyl chloride resin, PVDF resin, main plasticizer, auxiliary plasticizer, stabilizer, light stabilizer, antioxidant, compatibilizer, processing aid, colorant, Put into a high-speed mixer, perform high-speed mixing in the high-speed mixer, and transfer it to a cooling mixer for cooling after high-speed mixing; wherein, the high-speed mixing termination temperature is 100-150°C; the cold stirring termination temperature is 20-70°C;

[0060] (2) Plasticizing: Feed the mixture obtained in step (1) into a planetary extruder for plasticization; wherein, the temperature in each zone of the planetary extruder is 140-200° C., and the extrusion speed is 40-60 rpm;

[0061] (3) Calendering: Put the fully plasticized material obtained in step (2) into a filter to f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com