Light absorbing and heating functional fiber

A functional fiber, light absorption and heat generation technology, applied in the field of textile fibers, can solve the problems of single heat preservation method and poor heat preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

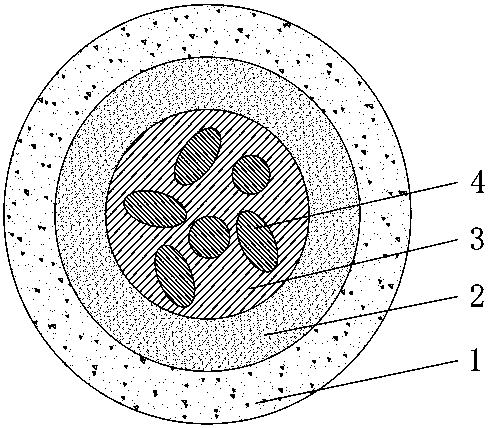

[0020] Such as figure 1 As shown, a light-absorbing and heat-generating functional fiber includes a light-absorbing layer 1, a heat-generating layer 2, and a heat storage layer 3 in sequence from the outside to the inside. The light-absorbing layer 1 is composed of the following components by weight: 80 parts of high polymer, 8 parts, 1 part of coupling agent, the heat generating layer 2 is composed of the following components by weight: 80 parts of high polymer, 10 parts of heat generating particles, 1 part of coupling agent, and the heat storage layer 3 is composed of the following components by weight : 80 parts of high polymer, 4 20 parts of thermal storage particles.

[0021] The polymer used in the light-absorbing layer 1 is polyethylene, the polymer used in the heat-generating layer 2 is polypropylene, the polymer used in the heat-storage layer 3 is polyester, the light-absorbing particles are carbon black, and the heat-generating particles are nano-titanium carbide, A...

Embodiment 2

[0024] Such as figure 1 As shown, a light-absorbing and heat-generating functional fiber includes a light-absorbing layer 1, a heat-generating layer 2, and a heat storage layer 3 in sequence from the outside to the inside. The light-absorbing layer 1 is composed of the following components by weight: 90 parts of high polymer, 15 parts, 2 parts of coupling agent, the heat generating layer 2 is composed of the following components by weight: 90 parts of high polymer, 13 parts of heat generating particles, 2 parts of coupling agent, and the heat storage layer 3 is composed of the following components by weight : 90 parts of high polymer, 4 30 parts of thermal storage particles.

[0025] The high polymer used in the light-absorbing layer 1 is polyamide, the high polymer used in the heat-generating layer 2 is polypropylene, the high polymer used in the thermal storage layer 3 is polyethylene, the light-absorbing particles are a mixture of carbon black and zirconia, and the heat-gen...

Embodiment 3

[0027] Such as figure 1 As shown, a light-absorbing and heat-generating functional fiber includes a light-absorbing layer 1, a heat-generating layer 2, and a heat storage layer 3 in sequence from the outside to the inside. The light-absorbing layer 1 is composed of the following components by weight: 100 parts of high polymer, 20 parts, 3 parts of coupling agent, the heat generating layer 2 is composed of the following components by weight: 100 parts of high polymer, 25 parts of heat generating particles, 3 parts of coupling agent, and the heat storage layer 3 is composed of the following components by weight : 100 parts of high polymer, 440 parts of thermal storage particles.

[0028] The high polymer used in the light-absorbing layer 1 is polyurethane, the high polymer used in the heat-generating layer 2 is polypropylene, the high polymer used in the thermal storage layer 3 is polyethylene, and the light-absorbing particles are a mixture of carbon black, zirconia and silicon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com