Fine-denier polypropylene spunbond needle-punched non-woven fabric with ultra high tensile stress at specific elongation and manufacturing process thereof

A technology of non-woven fabrics and polypropylene, which is applied in the direction of non-woven fabrics, rayon manufacturing, textiles and papermaking, etc. It can solve the problems of insufficient strength and high price of short-fiber needle-punched non-woven fabrics, and achieve superior functions and long service life , the effect of high mechanical index

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings. It should be understood that the preferred embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

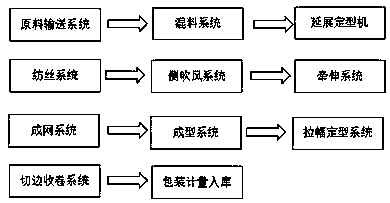

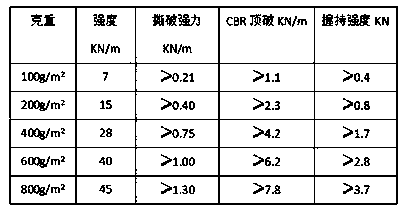

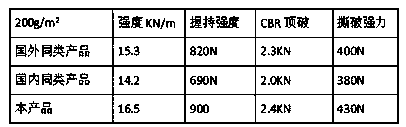

[0029] Please refer to Figure 1-3 As shown, the super-strength fixed-stretch fine-denier polypropylene spunbonded needle-punched nonwoven fabric is made of raw material polypropylene and auxiliary materials anti-ultraviolet masterbatch; It is made by mixing and extruding, spinning, cooling, drawing, separating and laying the net, reinforcing the fiber web with needle punching, tentering, and winding; when super-strength fixed-stretch fine-denier polypropylene needle-punched nonwovens The grammage is 800g / m2--200g / m2, and the tonnage corresponds to 1000 tons. When the grammage of the super-stretch fine-denier polypropylene needle-punched nonwoven fabric is 200g / m2--...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com