Hard hydrophobic coating with micro-nano structure and preparation method of hard hydrophobic coating

A technology of micro-nano structure and hydrophobic coating, which is applied in the direction of coating, metal material coating process, vacuum evaporation plating, etc., can solve the problems of easy aging and poor wear resistance of hydrophobic coating, so as to reduce surface wear and improve Effect of hardness and wear resistance, good anti-friction and self-lubricating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

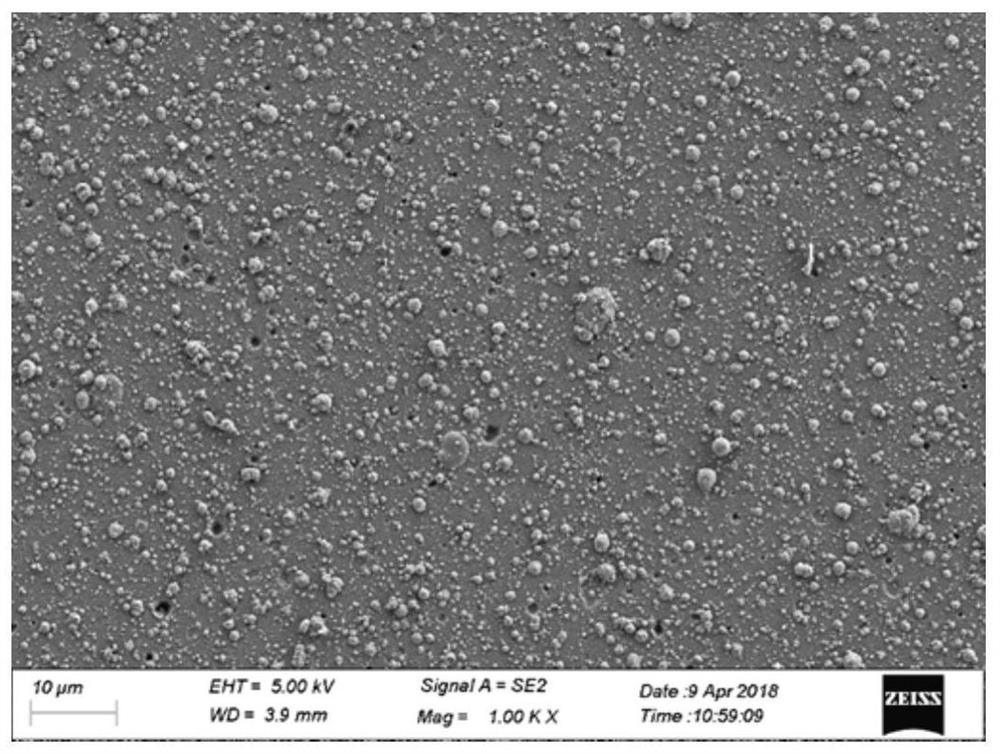

[0039] The 3×3cm high-speed steel sample block is used as the base material, and the specific implementation steps are as follows:

[0040] 1) Clean the surface of the high-speed steel substrate with acetone, alcohol and deionized water in sequence, and dry it with a hair dryer;

[0041]2) Deposit the Cr layer first by using multi-arc ion plating to deposit the coating:

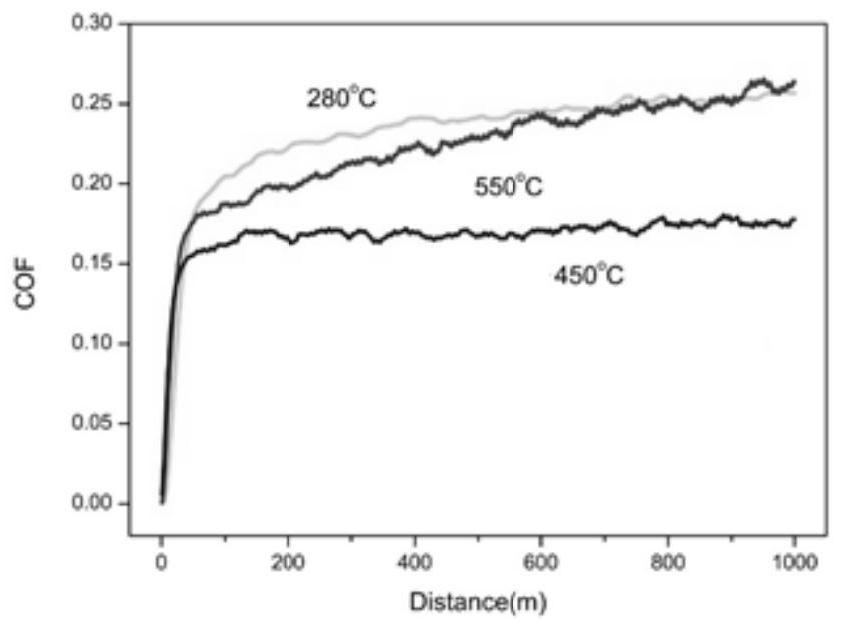

[0042] The working air pressure is 0.4Pa, the substrate bias voltage is -450V, the substrate temperature is 550℃, and the deposition time of Cr target alone is 10min;

[0043] Then deposit the CrTiAlN layer:

[0044] The working pressure is 2Pa, the substrate bias is -60V, and the Cr target and the TiAl target are co-sputtered for 120min under the condition that the flow ratio of argon and nitrogen is 1:9.

[0045] Finally deposit the CrTiAlCN layer:

[0046] The working pressure is 2Pa, the substrate bias is -60V, the Cr target and the TiAl target are co-sputtered under the condition that the flow ratio o...

Embodiment 2

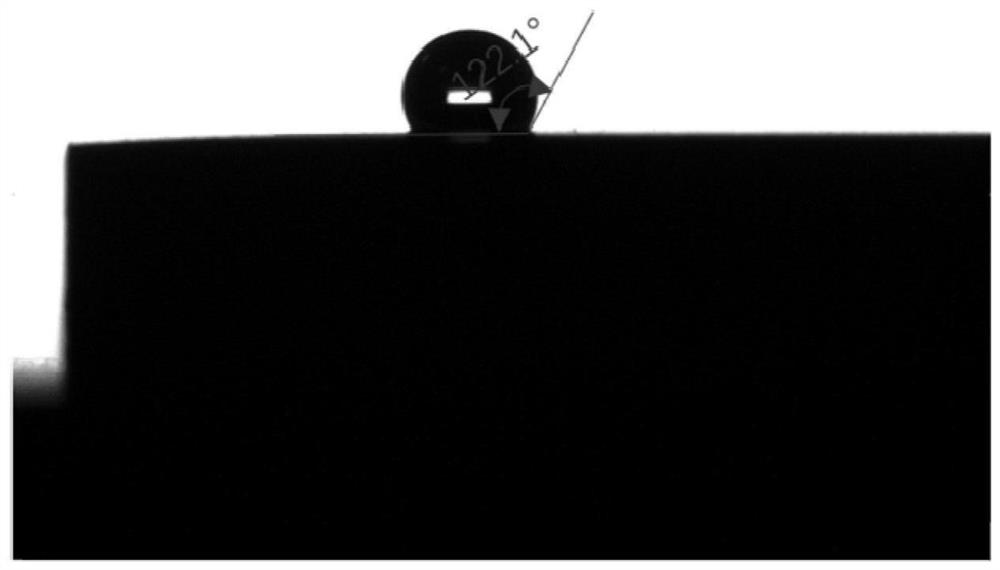

[0049] The 5×5cm P20 mold steel sample block is used as the base material, and the specific implementation steps are as follows:

[0050] 1) Clean the surface of the P20 steel substrate with acetone, alcohol and deionized water in sequence, and dry it with a hair dryer;

[0051] 2) Deposit the Cr layer first:

[0052] The working air pressure is 0.3Pa, the substrate bias voltage is -350V, the substrate temperature is 280℃, and the deposition time of Cr target alone is 10min;

[0053] Then deposit the CrTiAlN layer:

[0054] The working pressure is 2.2Pa, the substrate bias is -60V, and the Cr target and TiAl target are co-sputtered for 120min under the condition that the flow ratio of argon and nitrogen is 1:15;

[0055] Finally deposit the CrTiAlCN layer:

[0056] The working pressure is 2.2Pa, the substrate bias is -60V, the Cr target and the TiAl target are co-sputtered under the condition that the flow ratio of argon and nitrogen is 1:15, and a carbon ion beam with an e...

Embodiment 3

[0059] The 3×3cm H13 mold steel sample block is used as the base material, and the specific implementation steps are as follows:

[0060] 1) First clean the surface of the H13 steel substrate with acetone, alcohol and deionized water in sequence, and dry it with a hair dryer;

[0061] 2) Deposit the Cr layer first:

[0062] The working air pressure is 0.3Pa, the substrate bias voltage is -350V, the substrate temperature is 450℃, and the deposition time of Cr target alone is 10min;

[0063] Then deposit the CrTiAlN layer:

[0064] The working pressure is 2.2Pa, the substrate bias is -80V, and the Cr target and the TiAl target are co-sputtered for 120min under the condition that the flow ratio of argon and nitrogen is 1:20.

[0065] Finally deposit the CrTiAlCN layer:

[0066] The working pressure is 2.2Pa, the substrate bias is -80V, the Cr target and the TiAl target are co-sputtered under the condition that the flow ratio of argon and nitrogen is 1:20, and a carbon ion beam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com