Water-less printing and dyeing production line and production method applied to the production line

A production line and dyeing equipment technology, applied in the field of textile printing and dyeing, can solve the problems of longer production process, prone to wrinkles, low efficiency of textile printing and dyeing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

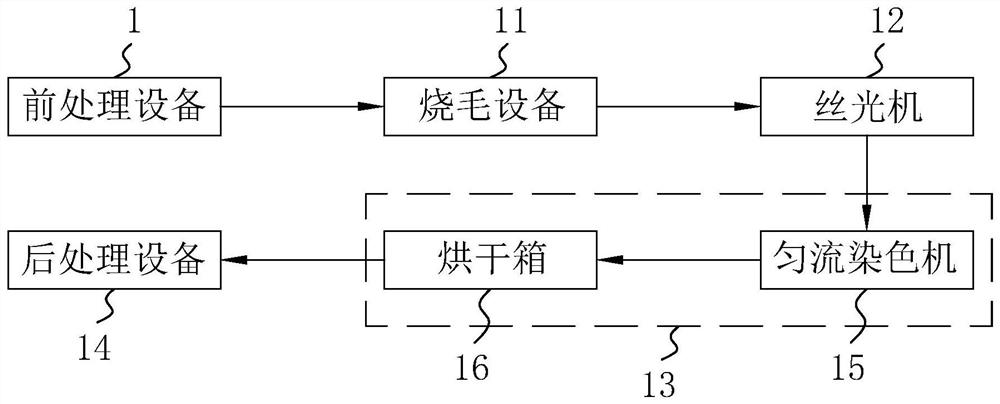

[0059] refer to figure 1 , is a water-less printing and dyeing production line disclosed in the present invention, including pretreatment equipment 1, singeing equipment 11, mercerizing machine 12, dyeing equipment 13 and finishing equipment 14 arranged in sequence along the cloth treatment process. The pre-treatment equipment 1 is used for desizing, refining and bleaching; the mercerizing machine 12 is used for treating the cloth with a concentrated alkali solution, so that the surface of the cloth shows a silky luster, and is also used for shaping the cloth; the dyeing device 13 is used for The cloth is dyed; the finishing equipment 14 sorts the cloth.

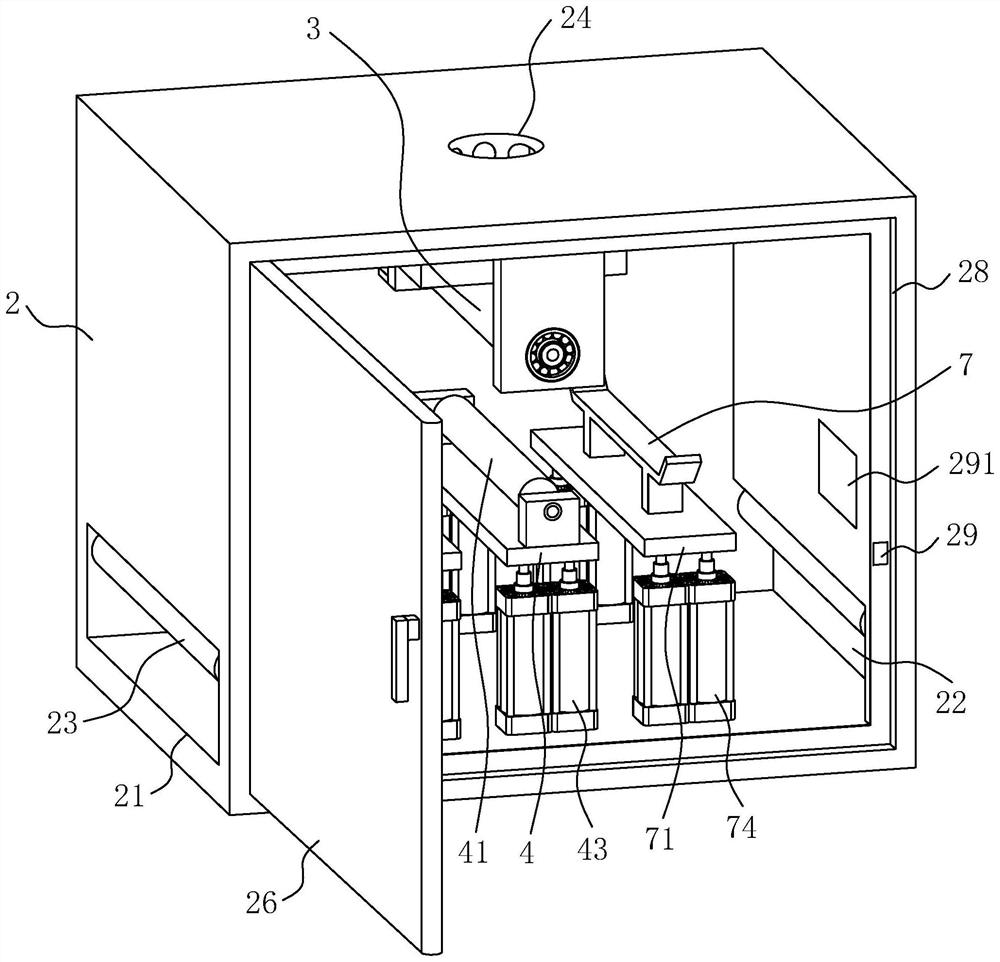

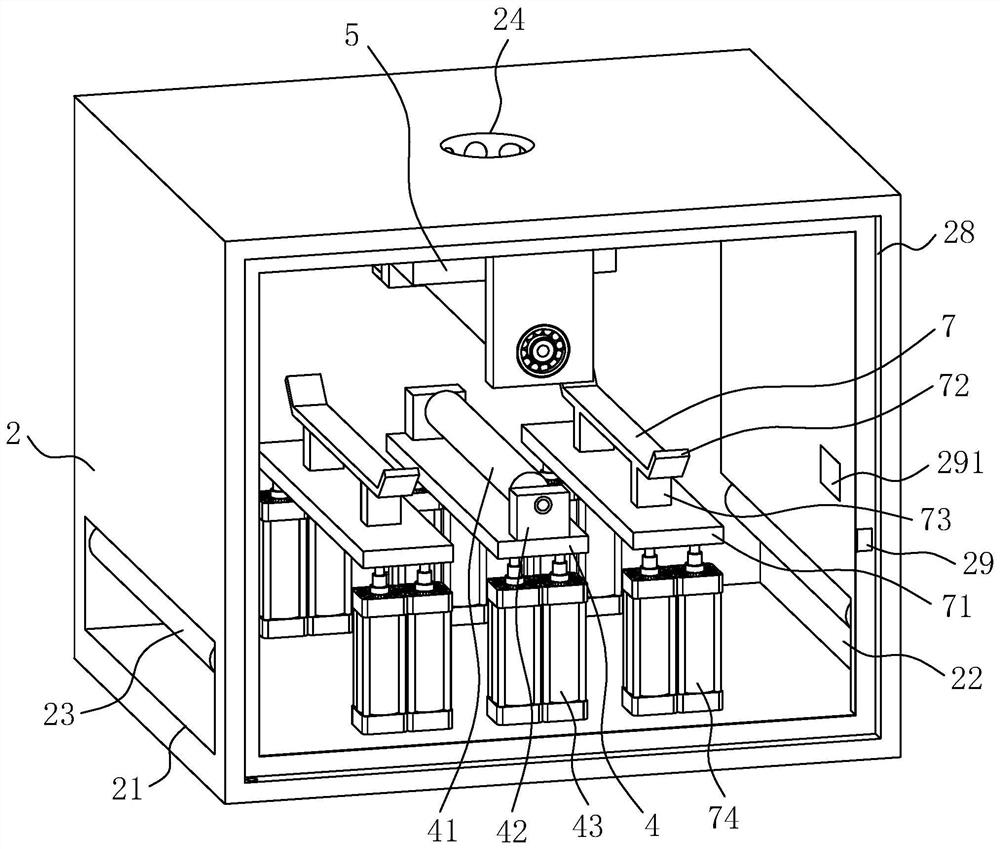

[0060] refer to figure 1 and figure 2 , The dyeing equipment 13 includes a uniform flow dyeing machine 15 and a drying box 16 arranged in sequence along the cloth processing process, and the drying box 16 includes a box body 2 . The two ends of the box body 2 along the cloth advancing direction are respectively provided ...

Embodiment 2

[0071] A kind of water-less printing and dyeing production method applied to the water-less printing and dyeing production line in embodiment one, with reference to figure 1 and figure 2 , which includes the following steps:

[0072] Step 1, feeding: the cloth output from the discharge end of the uniform flow dyeing machine 15 is sent into the box body 2 through the material inlet 21, and sent out of the box body 2 through the material outlet 22. The part of the cloth corresponding to the feed port 21 and the discharge port 22 is located below the corresponding protection roller 23 , and the part of the cloth corresponding to the pinch roller 3 is located between the pinch roller 3 and the stroke roller 41 .

[0073] Step 2, the whole material: place the cloth in the box body 2 on the receiving plate 7, and make the cloth be located between the two baffle plates 72 on the receiving plate 7.

[0074] Step 3, material clamping: close the box door 26, and make the driving ends o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com