Existing road underground drainage pipeline additionally installing method

An underground drainage and pipeline technology, applied in the sewer system, water supply device, waterway system, etc., can solve the problem of unplanned underground drainage network, affecting traffic, etc., to reduce damage to road structure strength, delay initial setting time, reduce impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

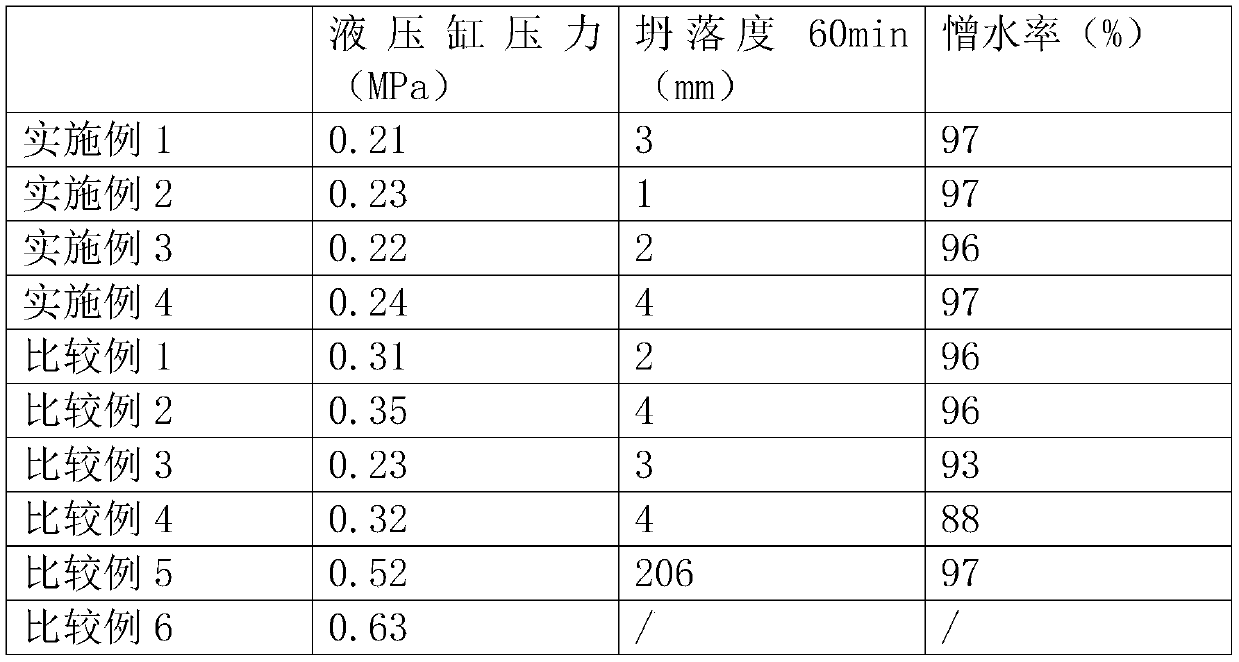

Examples

Embodiment 1

[0053] A method for adding an existing road underground drainage pipeline, the underground drainage pipeline includes a plurality of pipeline units, and the pipeline units are PE plastic pipes;

[0054] The existing road underground drainage pipeline installation method comprises the following steps:

[0055] S1 excavation of the construction well, details are as follows:

[0056] Carry out segmented construction according to the total length of the pipeline. In this embodiment, the construction length of each segment is 1km, measured from the beginning of the pipeline, marked at every 1km on the side of the road, and excavating the construction well at the marked position on the side of the road , the depth of the construction well is greater than the design depth of the underground drainage pipe, and the height of the bottom of the construction well is 1m lower than the design height of the bottom of the underground drainage pipe. A ladder is fixedly connected to the side w...

Embodiment 2

[0077] The difference with embodiment 1 is:

[0078] The specific differences between step S4 and step S7 in the existing road underground drainage pipeline installation method are as follows:

[0079] S4 Drilling and digging straight holes, details are as follows:

[0080] Use drilling equipment to drill along the extension direction of the design of the underground drainage pipeline to form a straight hole, and drill to connect to the adjacent underground construction room through the straight hole;

[0081] The inner diameter of the straight hole is 3cm larger than the designed outer diameter of the underground drainage pipe.

[0082] S7 grouting, the details are as follows:

[0083] Put two ring-shaped pouring formworks on the underground drainage pipe from both ends of the underground drainage pipe passing through the straight hole respectively, attach the pouring formwork to the side wall of the underground construction room with the straight hole, and pass the sealing...

Embodiment 3

[0085] The difference with embodiment 1 is:

[0086] The preparation method of the lubricated cement slurry comprises the following steps:

[0087] S01 Add 100kg of cement, 12kg of propylene glycol, 1.5kg of retarder, 4kg of lotus leaf powder, 4kg of polytetrafluoroethylene powder and 37kg of water into the stirring tank, and stir for 5min at a speed of 60r / min;

[0088] S02 Add 50kg of fumed silica, 26kg of talcum powder, and 31kg of waste tire rubber powder into the stirring tank at a rotation speed of 45r / min, stir for 5min at a rotation speed of 15r / min, and continue stirring until use is complete.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com