Flexible bionic tactile sensor based on microstructure and preparation method of flexible bionic tactile sensor

A tactile sensor and microstructure technology, which is applied in the sensor field to achieve the effects of good stability, convenient operation and sensitive response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

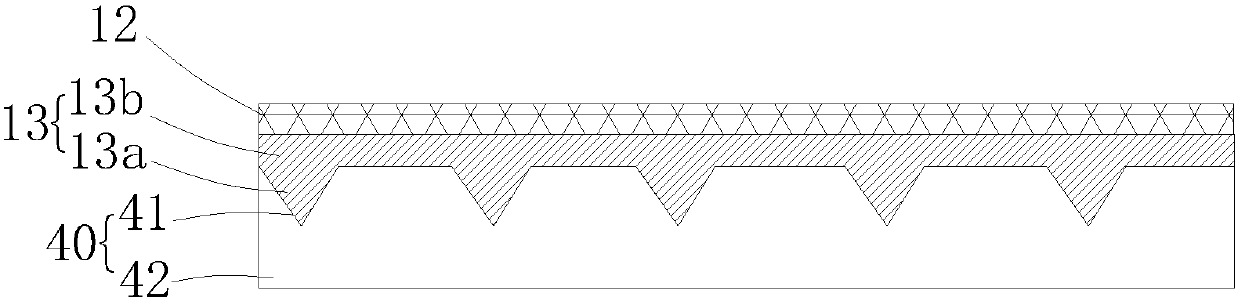

[0029] Such as Figure 1H As shown, the flexible bionic tactile sensor based on the microstructure of the embodiment of the present invention includes an imitation fingerprint layer 20 and two conductive structures 10 oppositely arranged, wherein each of the two conductive structures 10 includes a support layer 11, and is arranged on the support layer 11. The flexible layer 12 and the conductive sensitive layer 13 arranged on the flexible layer 12, the conductive sensitive layers 13 of the two conductive structures 10 are opposed to each other, and the imitation fingerprint layer 20 is arranged on the surface of one of the support layers 11 away from the flexible layer 12 .

[0030] The working principle of the above-mentioned tactile sensor is as follows: when an external force acts vertically on the upper and lower support layers 11, the effective contact area of the upper and lower conductive sensitive layers 13 changes, causing the resistance value of the tactile sensor ...

Embodiment 2

[0038] Figure 1A to Figure 1H Shows the flow chart of the preparation method of the microstructure-based flexible bionic tactile sensor according to the embodiment of the present invention, which includes the following steps:

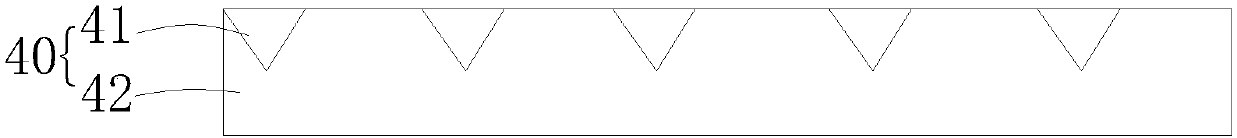

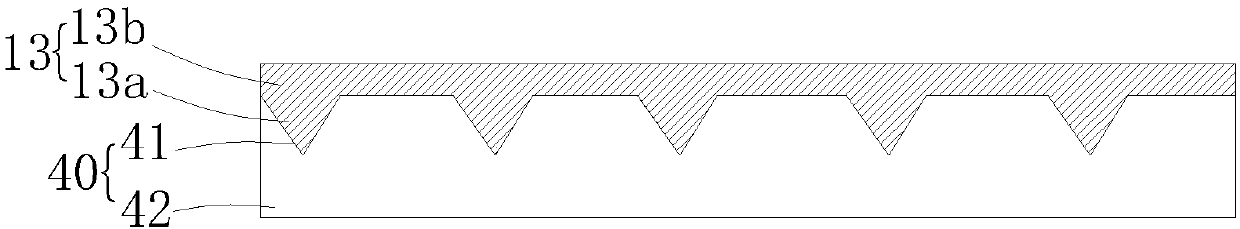

[0039] Step S1: Refer to Figure 1A with 1B , providing a first template 40 on which the conductive sensitive layer 13 is formed.

[0040] Specifically, the first template 40 includes a template body 42 and several blind holes 41 disposed on the template body 42 . The first template 40 is preferably a silicon-based template, and a blind hole 41 is etched on the template body 42 using a micromachining process commonly used in micro-electromechanical systems. The blind hole 41 is preferably an inverted regular pyramid structure, that is, an inverted pyramid structure, and the blind hole 41 The bottom surface of is a square with a side length of 10 μm, the height of the blind hole 41 is 7.06 μm, the angle between the side surface and the bottom surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bottom length | aaaaa | aaaaa |

| Bottom width | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com