Full-inorganic ultraviolet LED wafer-level package method

A wafer-level packaging and LED packaging technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of modern packaging requirements for hard-to-ultraviolet LEDs, high packaging costs, and low process integration, and meet long-term reliability requirements , reduce packaging cost, improve the effect of packaging integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

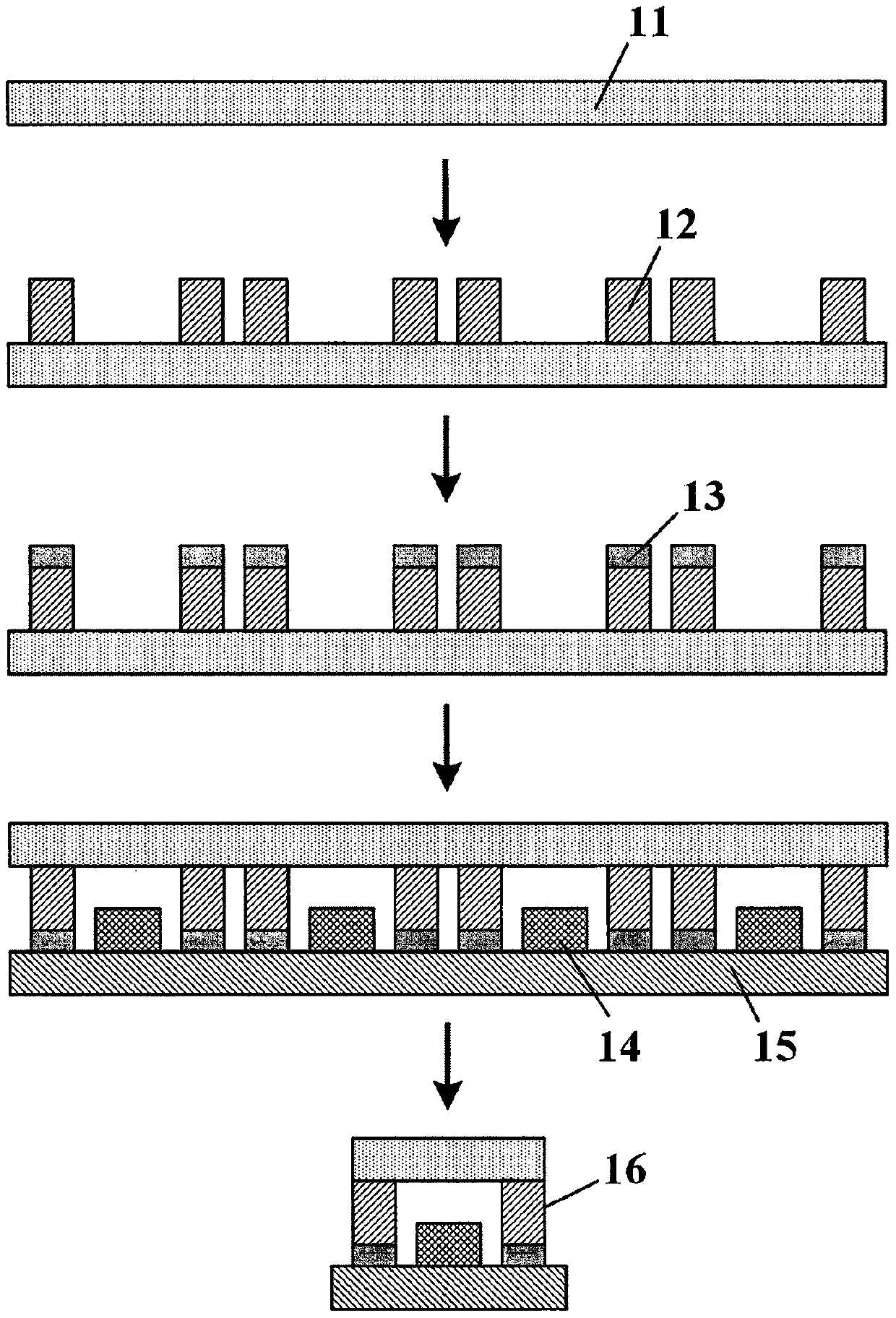

[0031] See figure 1 , This embodiment 1 provides an all-inorganic UV LED wafer-level packaging method, which as an example may include the following steps:

[0032] Step 1. First prepare glass slurry, mix glass powder, ceramic powder and binder, and stir them thoroughly. The components are set as follows: Low melting point borosilicate glass is selected for glass powder and its content is the total weight of the slurry 70%, the ceramic powder chooses alumina material and its content is 20% of the total weight of the slurry, and the glass powder and ceramic powder have a particle size of 5-10μm, and the binder is a mixture of ethyl cellulose and terpineol. , And the mixing amount is respectively 2% and 8% of the total weight of the slurry; then a 0.5mm thick quartz glass sheet is selected as the glass cover 11, and multiple round glasses are printed on the glass cover 11 by 3D printing technology Then place the glass cover 11 in a high-temperature furnace, first dry at 250°C for 2...

Embodiment 2

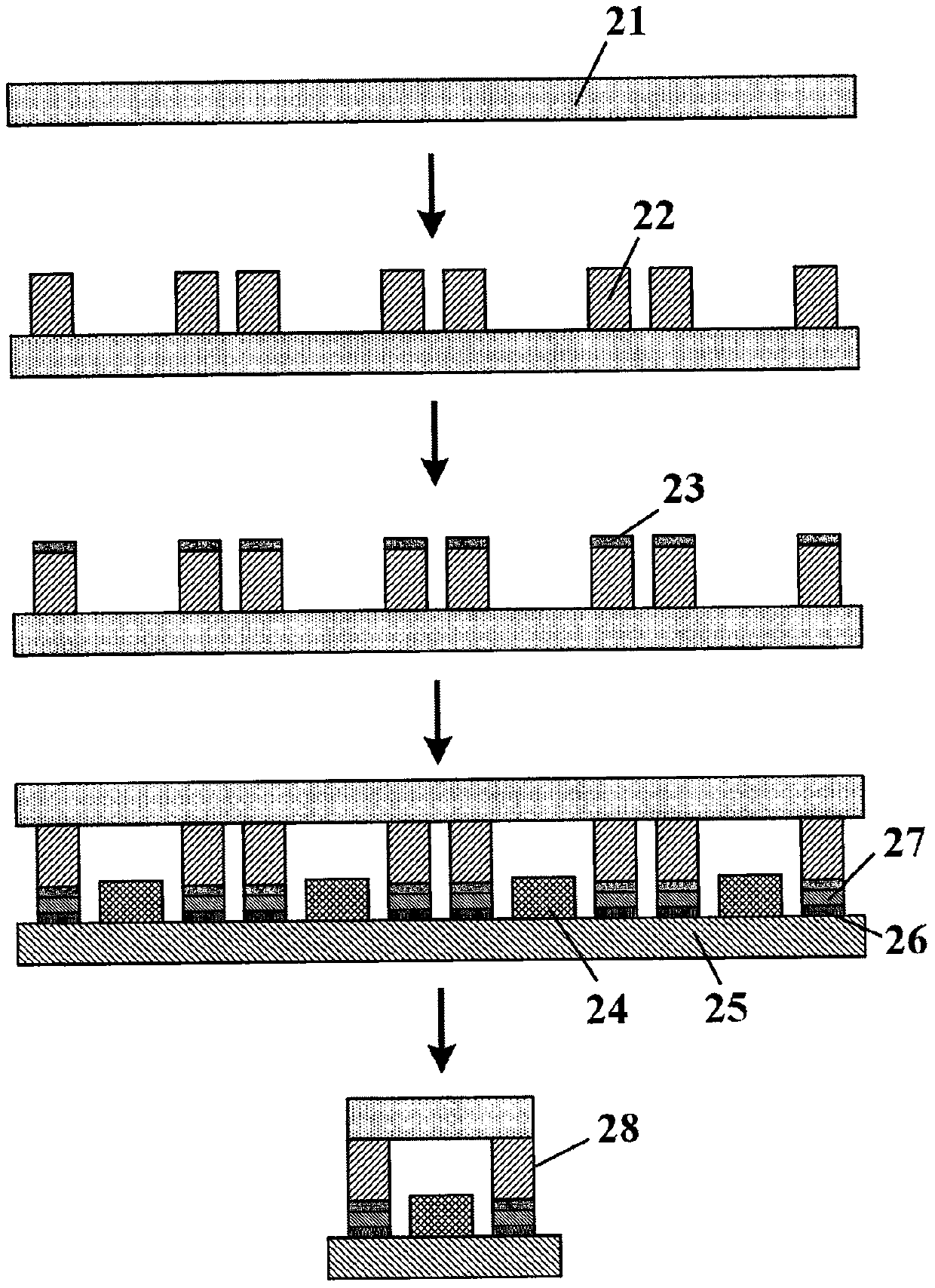

[0038] See figure 2 , This embodiment 2 provides a method for all-inorganic UV LED wafer-level packaging, which as an example may include the following steps:

[0039] Step 1. First prepare glass slurry, mix glass powder, ceramic powder and binder, and stir them thoroughly. The components are set as follows: Low melting point borosilicate glass is selected for glass powder and its content is the total weight of the slurry 65%, ceramic powder chooses alumina material and its content is 20% of the total weight of the slurry, and the particle size of glass powder and ceramic powder is 5-10μm, and the binder is selected as a mixture of ethyl cellulose and terpineol , And its content is respectively 5% and 10% of the total weight of the paste; then a 0.5mm thick quartz glass sheet is selected as the glass cover 21, and a square glass paste is printed on the glass cover 21 by multiple screen printing The material ring is dried at 200°C for 30 minutes after each printing, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com