Self-repairing method for phased-array antenna microsystem integrated packaging structure

A phased array antenna and integrated packaging technology, which is applied in the direction of antenna support/mounting device, antenna, antenna array, etc., can solve the problems of deterioration of electrical performance of devices, incomplete melting of solder balls, shortening service life of devices, etc., and meet the requirements of Long-term reliability requirements, improving electrical interconnection reliability, and increasing the effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

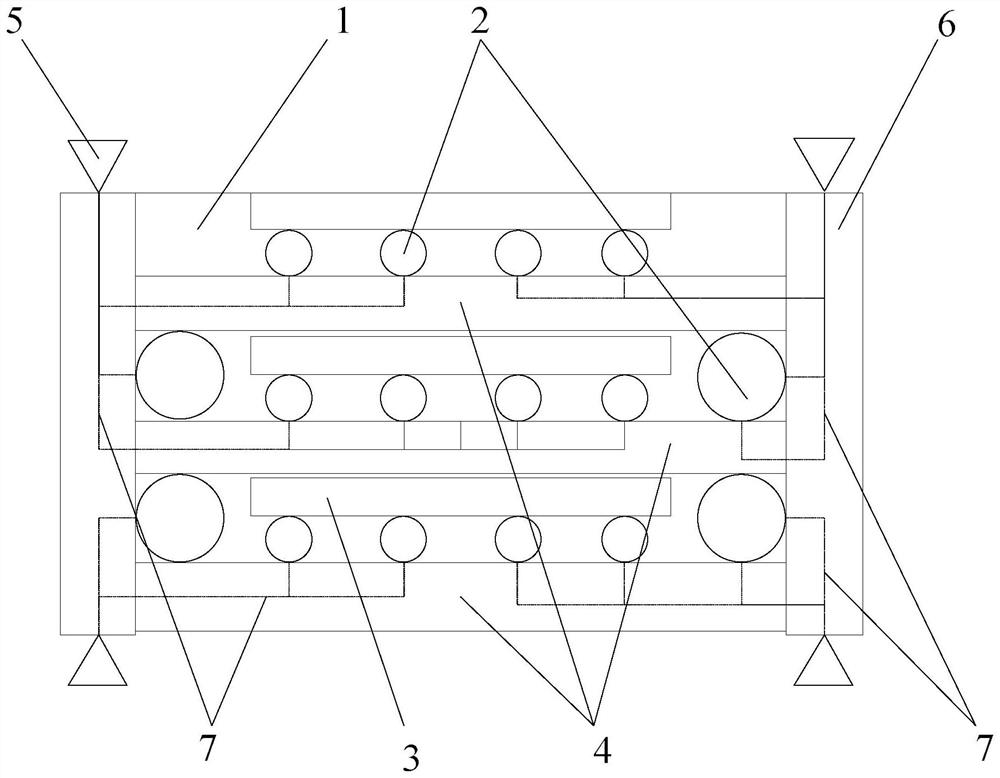

[0017] refer to figure 1 . According to the present invention, arrays are made on the top and bottom of the packaging substrate 4 that encapsulates the active components 3, and the solder balls are used as the I / O terminals of the circuit to connect with the printed circuit board PCB, through the interconnection solder joints 2 network solder ball arrays and Embedded wafer-level ball grid array eWLB realizes single-chip wafer-level packaging including baseband, processor, memory, power management, and radio frequency transceivers, through the layer-by-layer interconnection between each redistribution layer and the packaging substrate 4 At the same time, the electrical signal transmission between the packaging substrate 4 is also realized through the interconnection solder joints 2, forming a microsystem package 1 for packaging microsystem integrated components; a repairable package carrier 6 is arranged at both ends of the microsystem package 1, and can be placed on the two en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com