An all-inorganic UV LED wafer-level packaging method

A wafer-level packaging and LED packaging technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of modern packaging requirements for difficult-to-UV LEDs, high packaging costs, and low process integration, and meet long-term reliability requirements. , The effect of reducing packaging cost and improving packaging integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

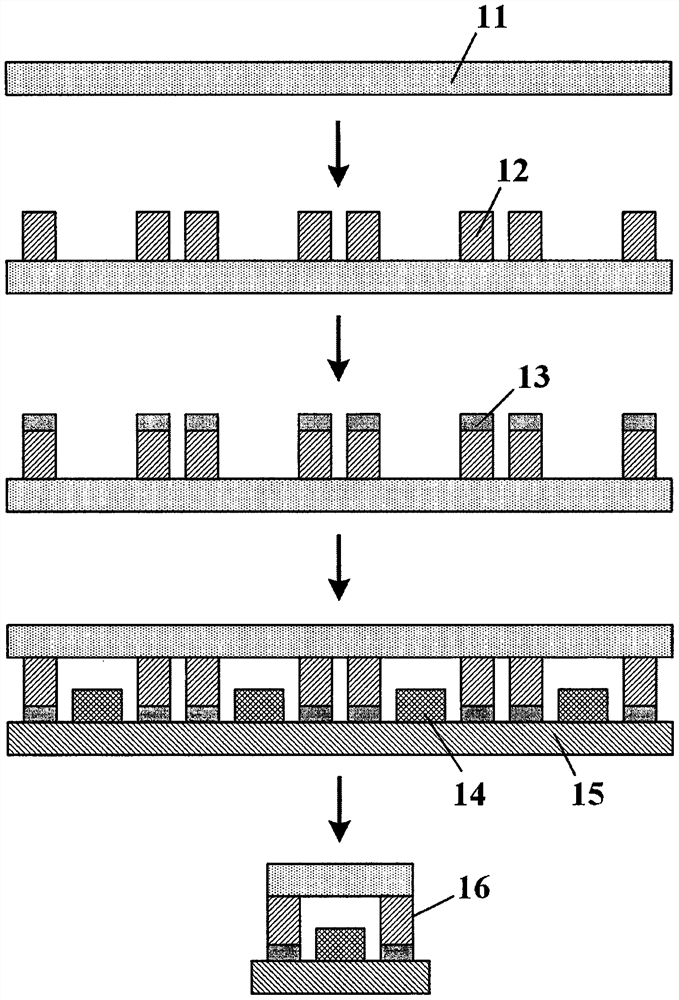

[0031] see figure 1 , the embodiment 1 provides a method for all-inorganic ultraviolet LED wafer-level packaging, which may include the following steps as an example:

[0032] Step 1, first prepare the glass slurry, mix the glass powder, ceramic powder and binder and fully stir, the components are set as follows: the glass powder is selected from low-melting point borosilicate glass and its dosage is 1% of the total weight of the slurry 70%, the ceramic powder is made of alumina material and its dosage is 20% of the total weight of the slurry, and the particle size of the glass powder and ceramic powder is 5-10 μm, and the binder is a mixture of ethyl cellulose and terpineol , and its dosage is respectively 2% and 8% of the total weight of the slurry; then a quartz glass sheet with a thickness of 0.5mm is selected as the glass cover plate 11, and a plurality of circular glass plates are printed on the glass cover plate 11 by 3D printing technology The slurry ring, and then pl...

Embodiment 2

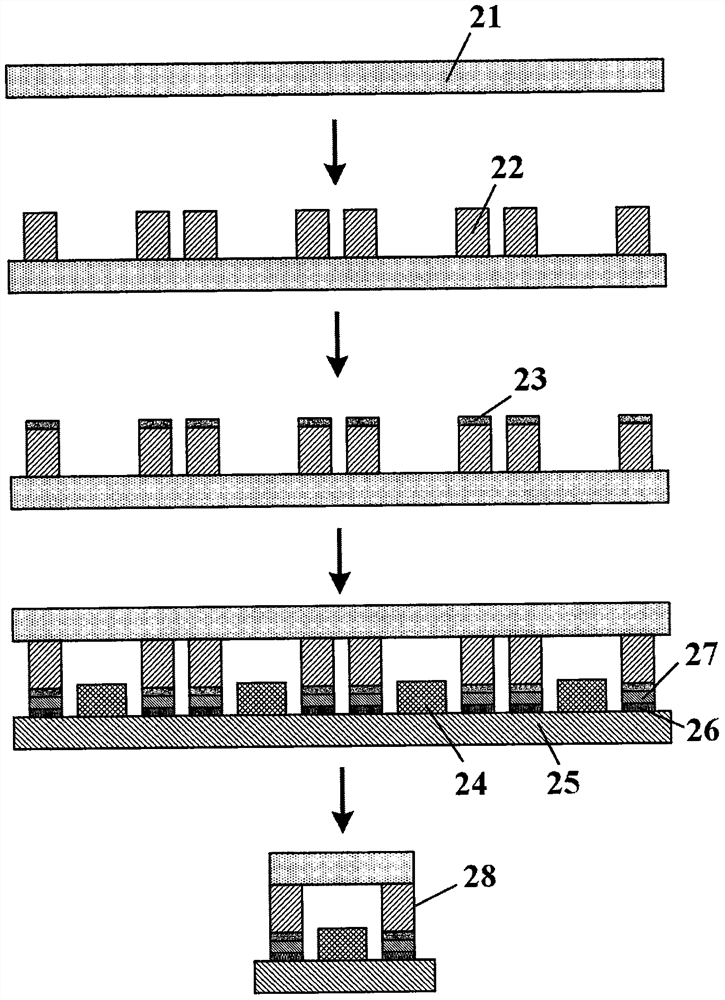

[0038] see figure 2 , this embodiment 2 provides a method for all-inorganic ultraviolet LED wafer-level packaging, which may include the following steps as an example:

[0039] Step 1, first prepare the glass slurry, mix the glass powder, ceramic powder and binder and fully stir, the components are set as follows: the glass powder is selected from low-melting point borosilicate glass and its dosage is 1% of the total weight of the slurry 65%, the ceramic powder is made of alumina material and its dosage is 20% of the total weight of the slurry, and the particle size of the glass powder and ceramic powder is 5-10 μm, and the binder is a mixture of ethyl cellulose and terpineol , and its dosage is respectively 5% and 10% of the total weight of the slurry; then select a quartz glass sheet with a thickness of 0.5mm as the glass cover plate 21, and print a square glass slurry on the glass cover plate 21 by multiple screen printing The material ring is dried at 200°C for 30 minutes ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com