Polyarylene sulfide resin composition and insert molding

A resin composition, polyarylene sulfide technology, applied in the coating and other directions, can solve the problems of increasing the absolute amount of warpage and reducing dimensional accuracy, and achieve the effects of excellent low warpage and high and low temperature impact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0062] The preparation of the resin composition can be easily prepared by the equipment and method generally used as the conventional preparation method of the resin composition. For example, any of the following methods can be used: method 1), after mixing the components, kneading and extruding using a single-screw extruder or a twin-screw extruder to prepare pellets, and then molding; method 2), Temporarily prepare pellets with different compositions, mix a predetermined amount of the pellets and shape, and obtain a molded product of the target composition after molding; method 3), directly inject one or more of the components into the molding machine; and so on. In addition, a method of forming a part of the resin component into a fine powder, and mixing and adding the other components is a preferable method in order to achieve uniform mixing of these components.

[0063] [Insert molding]

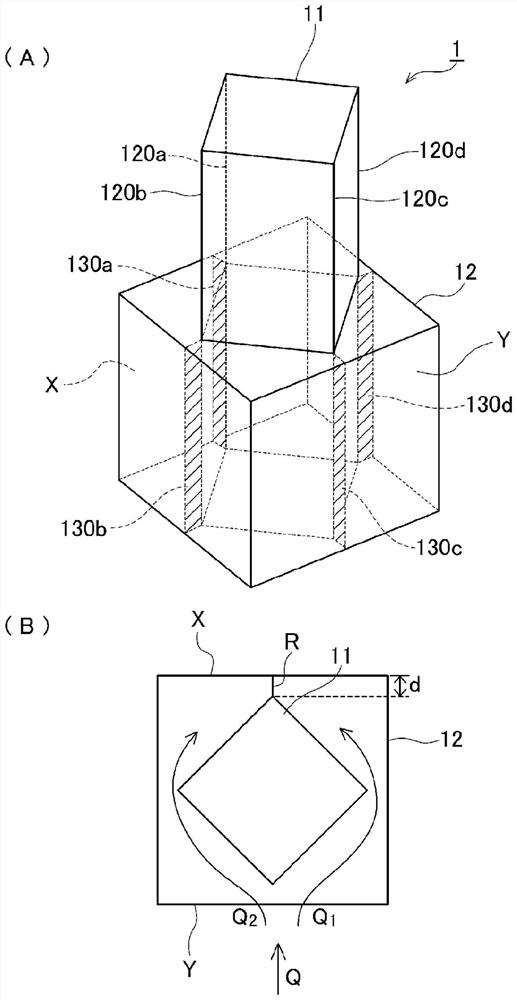

[0064] figure 1 An example of the insert-molded product of the present embodiment...

Embodiment 1~4、 comparative example 1~5

[0074] The polyarylene sulfide-based resin, the inorganic filler, and the olefin-based copolymer were dry-blended at the compositions and content ratios shown in Table 1 using the materials shown below. This was put into a twin-screw extruder with a barrel temperature of 320° C., and melt-kneaded to obtain resin composition pellets of Examples and Comparative Examples.

[0075] Polyarylene sulfide resin A: polyphenylene sulfide resin (PPS), "Fortron KPS" manufactured by Kureha Corporation (melt viscosity: 20 Pa·s (shear rate: 1216 sec) -1 , 310℃))

[0076] Plate-shaped inorganic filler B1: glass flake, average particle size (50% d) 623 μm, average thickness 5 μm, “Flexa REFG-108” manufactured by Nippon Sheet Glass Co., Ltd.

[0077] Fibrous inorganic filler B2: glass fiber, average fiber diameter 10.5 μm, average length 3 mm, “chopped fiber ECS03T-747H” manufactured by Nippon Electric Glass Co., Ltd.

[0078] Powdered and granular inorganic filler B3: calcium carbonate, aver...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com