A kind of preparation method and product of copper-plated polymer film

A polymer film and polymer technology, which is applied to flat products, other household appliances, pressure inorganic powder coating, etc., can solve the problems of long production cycle, low production efficiency, and film deformation, so as to reduce the production cycle and improve production Efficiency, good planarity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

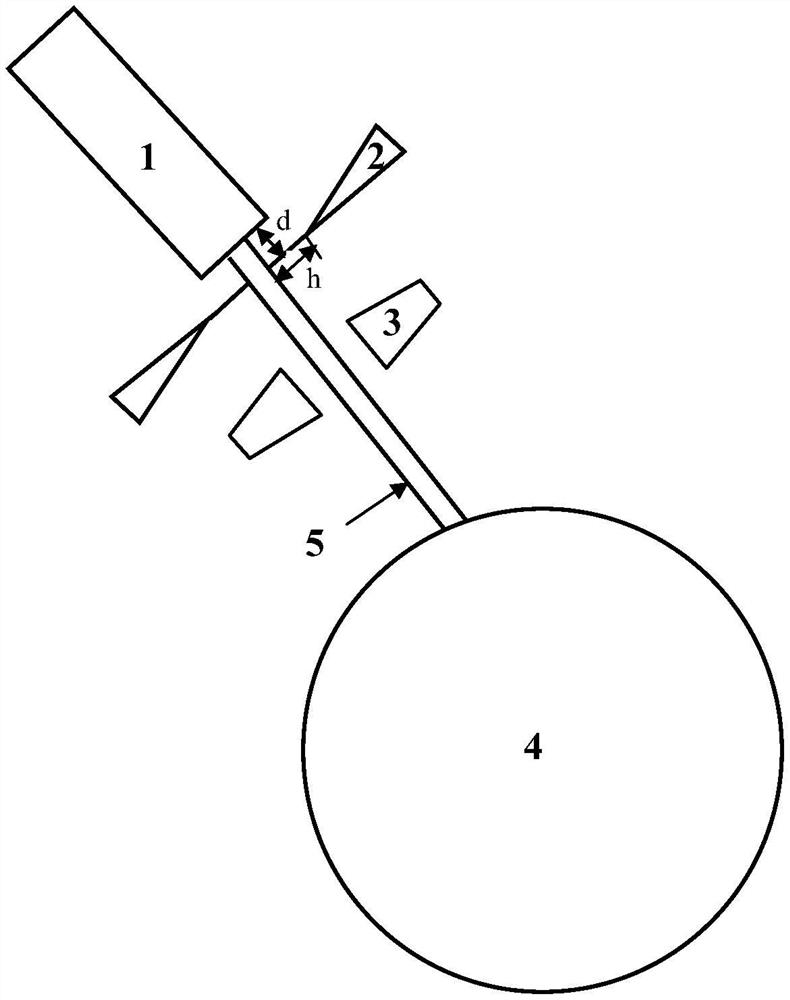

[0057] Figure 1 Apparatus diagram of the in-line copper coating process portion using the preparation process of the present invention. Comprising die 1 and polymer melt 5, polymer melt 5 extruded by die 1, polymer melt 5 is successively provided with nozzle 2, suction air outlet 3 and quench roller 4.

[0058] Nozzle 2 is a set of two, symmetrically set above and below the polymer melt 5. The vertical distance h between nozzle 2 and polymer melt 5 is 0.8cm and the horizontal distance d from die 1 is 1.5 cm. The nozzle 2 is in the shape of a crack, the width of the gap is 0.01mm, and the length is 0.6m. The nozzle 2 is connected to the silo where the nano copper powder is stored.

[0059] Suction port 3 is also a set of two, symmetrically set above and below the polymer melt 5. The vertical height of the suction port 3 from the polymer melt 5 is 0.8cm, and the horizontal distance from the nozzle 2 is 2 cm. Nano copper powder is compressed gas is transported to the upper and lowe...

Embodiment 1

[0061] First of all, the solid polyphenylene sulfide powder (the manufacturer is Zhejiang Xinhecheng Special Materials Co., Ltd., the grade is NHU-PPS3508P, the average weight weight is 60000 ~ 65000) is melted, and the twin screw extruder is extruded into a granular solid, and then put into the vacuum to dry, and the excess water is taken away by controlling the dry nitrogen passed in, as the final raw material for making the film.

[0062] The dried granular material is fed into a twin screw extruder for melting, metering, and feeding to the die, and the temperature of the melt extruded by the die is controlled to 285 °C. At the same time as the die is extruded, the nozzle extrudes copper powder to the surface of the melt, wherein the copper powder D50 is 40nm, the compressed air pressure is 0.5MPa, the suction air pressure is 8000Pa, and the speed of the cold roller is 50m / min, resulting in a sheet coated with copper.

[0063] Then the sheet is sent into the longitudinal stretc...

Embodiment 2

[0067] In the present embodiment, the copper powder D50 is 50nm, the compressed air pressure is 0.5MPa, the air pressure at the inlet is 8000Pa, and the speed of the quenching roller is 50m / min.

[0068]In addition, the ppS film is made using the same steps as In Example 1.

[0069] For the PPS film obtained by the above method, the evaluation results are shown in Table 1, and the film warpage performance is excellent, and the thickness of the copper layer as a buffer layer reaches the nanometer level and the uniformity is excellent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com