Integrated multifunctional traditional Chinese medicine pill making machine

A pill making machine and multi-functional technology, which is applied in the direction of making medicines into special physical or taking forms of devices, etc. Solve problems such as airflow in the chamber, and achieve the effect of being beneficial to equipment production, improving extraction efficiency and extraction effect, and overcoming technical defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

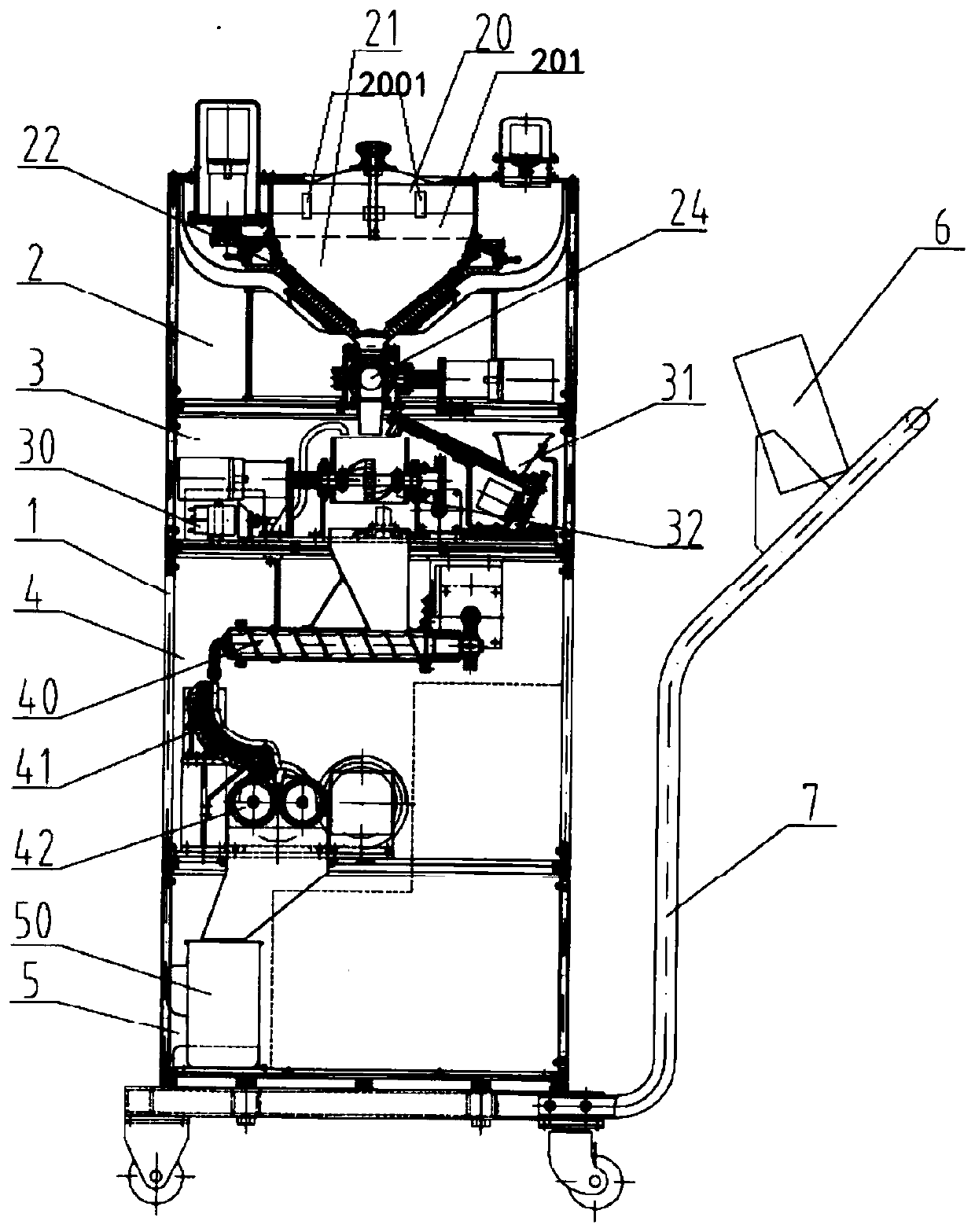

[0024] On the traditional Chinese medicine pill making machine disclosed in Embodiment 1 of Chinese patent application 201510724225.6, the main material feeding mechanism 20 in the decoction area 2 is movably arranged on the decoction chamber 21, and the main material feeding mechanism passes through the through hole at the bottom of the hopper 201 It communicates with the decoction chamber 21. During the working process of the pill making machine, the solvent vapor in the decoction chamber 21 enters the hopper 201 through the through hole at the bottom of the hopper 201, and steam extracts the medicinal materials in the hopper. The through hole at the bottom of the hopper 201 enters the decoction chamber 21, and the solvent vapor in the hopper 201 enters the cooling device 2001 through the through hole on the hopper cover. Enter the decoction chamber 21 through the through hole at the bottom of the hopper 201 . The scraping mechanism 22, the valve mechanism 24 of the torment ...

Embodiment 2

[0025] Embodiment 2 effect comparison

[0026] Take Prunella vulgaris, use water as the extraction solvent, use dextrin and hydroxypropyl cellulose as auxiliary materials, prepare Prunella vulgaris pellets with the pellet making machine of Example 1 of the present application and the pellet making machine of Example 1 of patent application 201510724225.6 respectively, press The same amount of feed and the same extraction time, with ursolic acid as a quantitative component, determined by HPLC, the content of ursolic acid in the Prunella vulgaris pills prepared by the two pill-making machines was respectively determined. Through three batches of parallel tests, the results show that the content of ursolic acid in the Prunella vulgaris pills made by the pelletizing machine in Example 1 of the present application is higher than the content of ursolic acid in the Prunella vulgaris pellets made by the pelletizing machine in Patent Application 201510724225.6, and the average content i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com