A Plasma Cutting Process for Realizing Ultra-Narrow Cutting Road

An ultra-narrow slit and plasma technology, which is applied in the direction of plasma welding equipment, welding/welding/cutting items, manufacturing tools, etc., can solve problems such as product strength decline, product chip rupture, and difficulty in ultra-narrow slit cutting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

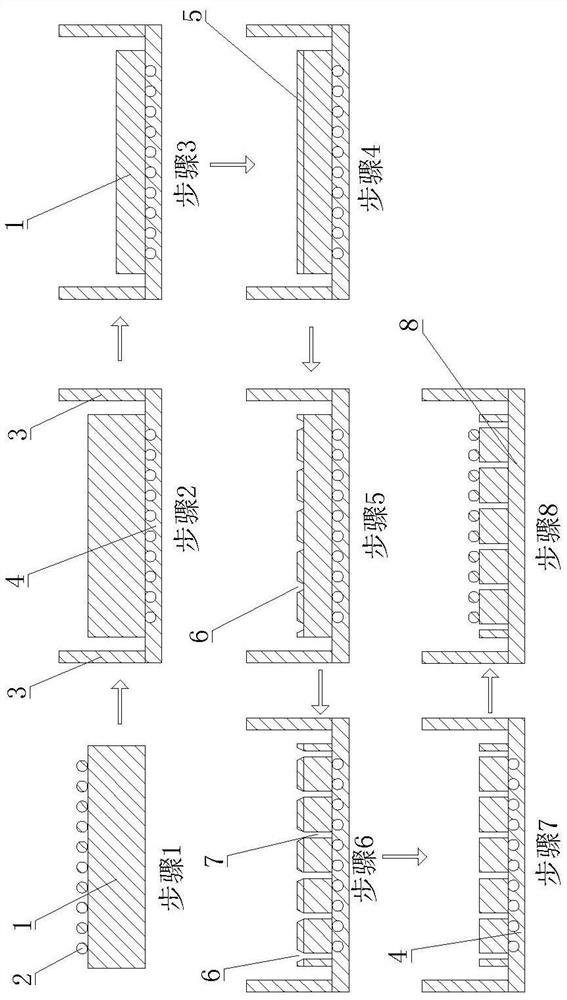

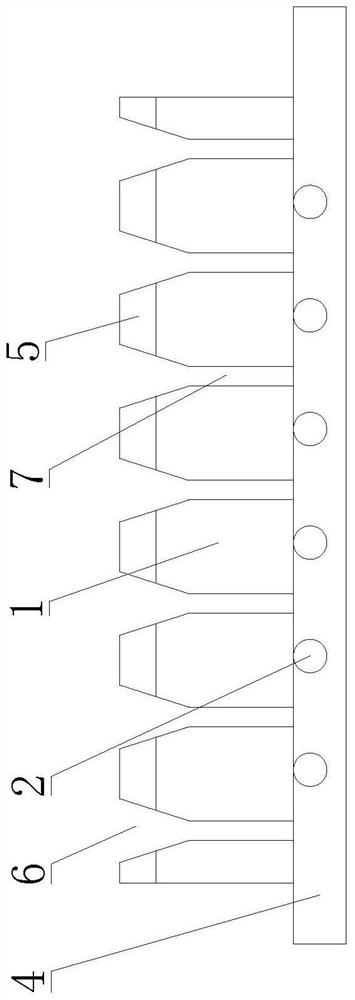

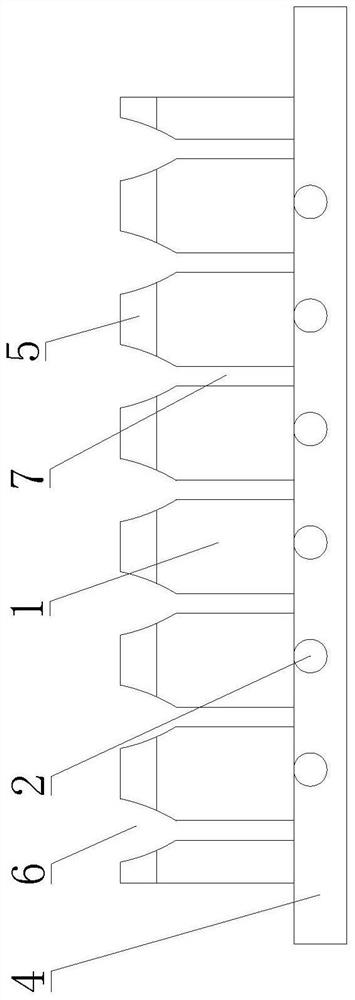

[0026] Such as figure 1 Shown, embodiment one: a kind of technology that plasma cutting realizes ultra-narrow cutting line, it comprises the following process steps:

[0027] Step 1: Do ball planting 2 on the front side of the semiconductor wafer 1 by solder paste printing and reflow soldering process. The solder paste printing is to print the solder paste on the front side of the semiconductor wafer 1 by using the movement of the solder paste scraper of the solder paste printing machine. The angle of the paste scraper is 30 degrees, and the movement speed is 5 mm / s; then, the solder paste is melted and soldered by the reflow process to form solder balls 2, and the peak temperature of the reflow soldering is 213 degrees;

[0028] Step 2: Attach the metal ring 3 whose size is suitable for the semiconductor wafer 1 on the BG-UV film 4 by roller pressure, then turn over the semiconductor wafer 1 processed in step 1, and make it face down by roller pressure Mounted on the inner s...

Embodiment 2

[0036] Embodiment 2: A process for realizing ultra-narrow cutting lines by plasma cutting, which includes the following process steps:

[0037] Step 1: Do ball planting 2 on the front side of the semiconductor wafer 1 by solder paste printing and reflow soldering process. The solder paste printing is to print the solder paste on the front side of the semiconductor wafer 1 by using the movement of the solder paste scraper of the solder paste printing machine. The angle of the paste scraper is 60 degrees, and the movement speed is 60 mm / s; then the solder paste is melted and soldered through the reflow soldering process, and the peak temperature of the reflow soldering is 213 degrees;

[0038]Step 2: Attach the metal ring 3 whose size is suitable for the semiconductor wafer 1 on the BG-UV film 4 by roller pressure, then turn over the semiconductor wafer 1 processed in step 1, and make it face down by roller pressure Mounted on the inner side of the metal ring 3, all the balls 2 ...

Embodiment 3

[0046] Embodiment 3: A process for realizing ultra-narrow cutting lines by plasma cutting, which includes the following process steps:

[0047] Step 1: Do ball planting 2 on the front side of the semiconductor wafer 1 by solder paste printing and reflow soldering process. The solder paste printing is to print the solder paste on the front side of the semiconductor wafer 1 by using the movement of the solder paste scraper of the solder paste printing machine. The angle of the paste scraper is 45 degrees, and the movement speed is 27.5 mm / s; then the solder paste is melted and soldered through the reflow process, and the peak temperature of the reflow soldering is 213 degrees;

[0048] Step 2: Attach the metal ring 3 whose size is suitable for the semiconductor wafer 1 on the BG-UV film 4 by roller pressure, then turn over the semiconductor wafer 1 processed in step 1, and make it face down by roller pressure Mounted on the inner side of the metal ring 3, the ball planting 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com