Concrete reinforcing agent

A concrete reinforcing agent, a special technology, applied in the field of concrete reinforcing agent, can solve the problems of compressive strength slump time, limited strengthening effect of setting time, unable to meet customer's directional needs, limited degree of concrete replacement, etc., to improve the impermeability level , protect the environment, reduce the effect of drying shrinkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

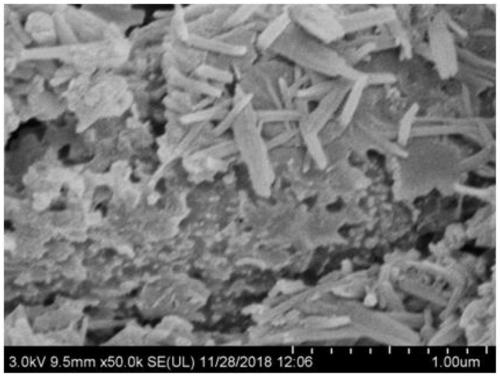

Image

Examples

Embodiment 1~3 and comparative example 1~2

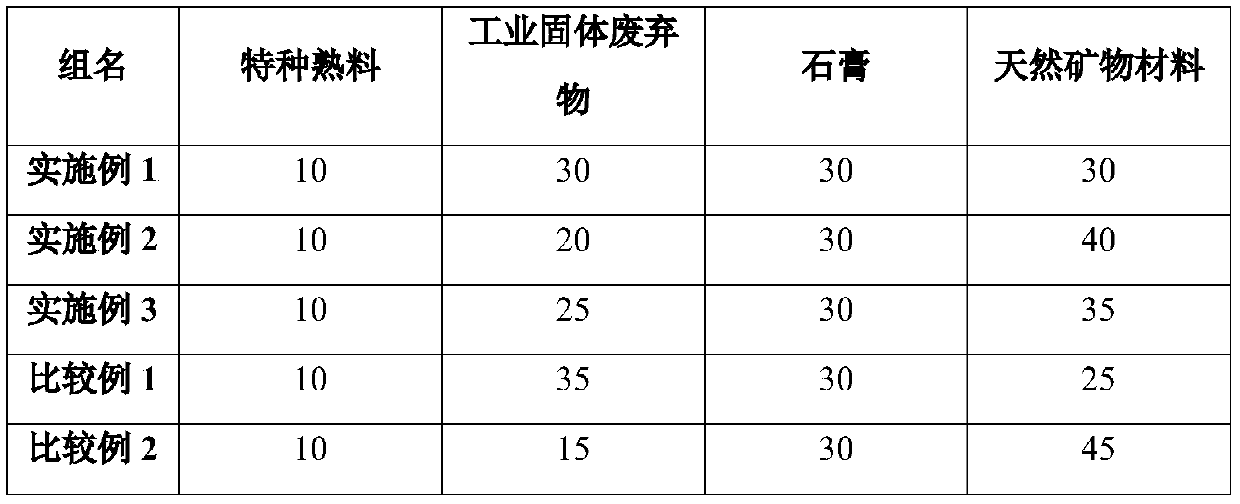

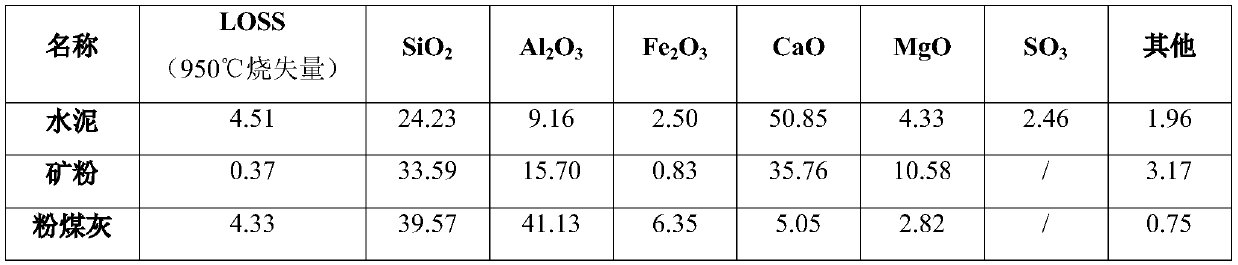

[0045] The prepared concrete reinforcing agent of embodiment 1~3 and comparative example 1~2 comprises special clinker, industrial solid waste, gypsum, natural mineral material, and its parts by weight are shown in table 1 below; 5% of the total weight of the concrete reinforcing agent is an internal curing continuous stimulating agent.

[0046] The parts by weight of the raw material of table 1 embodiment 1~3 and comparative example 1~2, unit: part

[0047]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com