Carbon fiber cluster sample preparation device and carbon fiber cluster preparation method

A carbon fiber and clustering technology, which is applied in the field of sample preparation devices, can solve problems such as changes in sample compactness, inability to accurately determine the filling rate of carbon fibers, and insufficient internal smoothness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] The present invention will be described in detail below with reference to the accompanying drawings and examples.

[0064] This embodiment provides a carbon fiber bundle sample preparation device, which is used to prepare a carbon fiber bundle sample, and the carbon fiber bundle sample prepared by the device can measure the axial thermal diffusivity of the carbon fiber by a flash method.

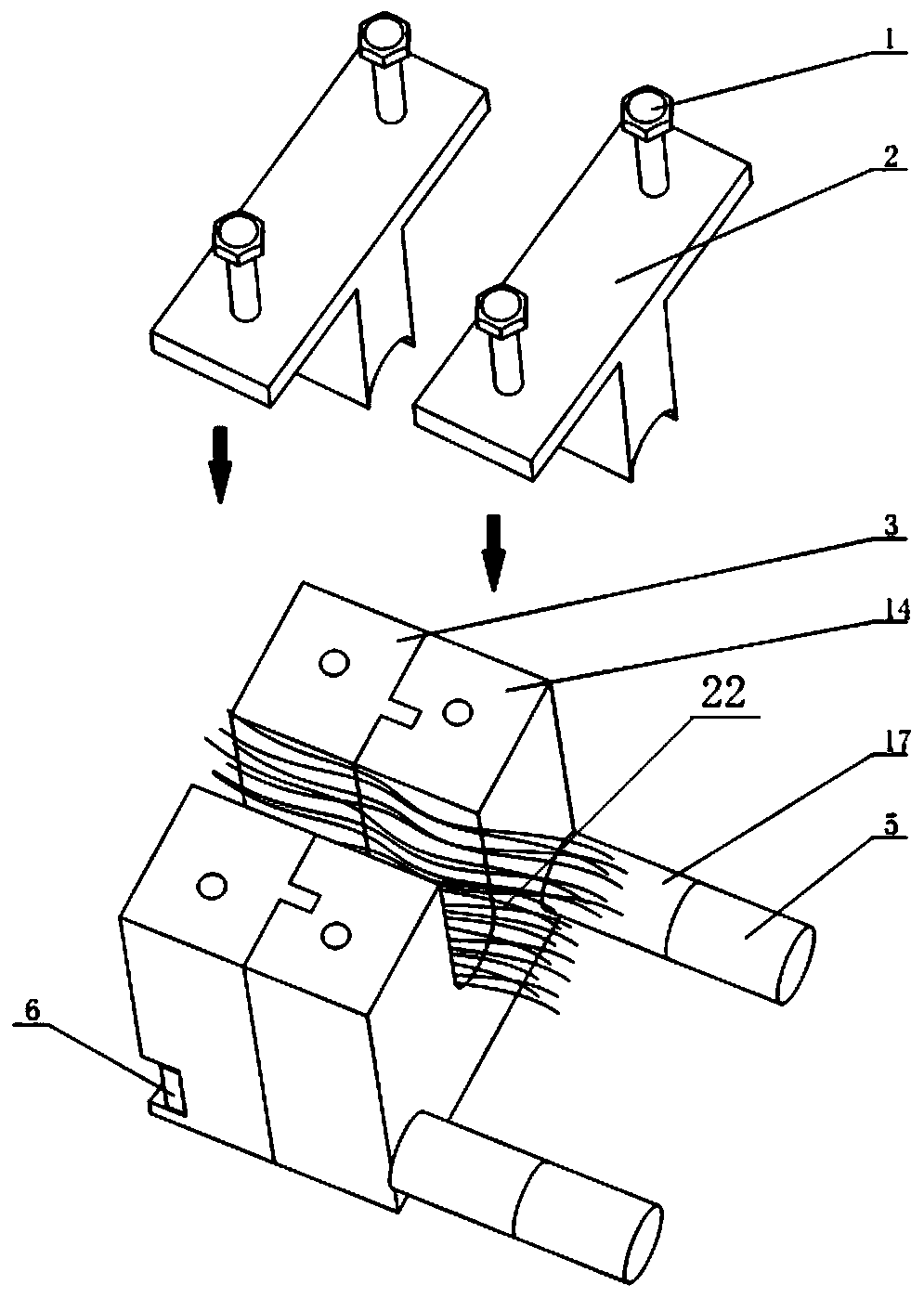

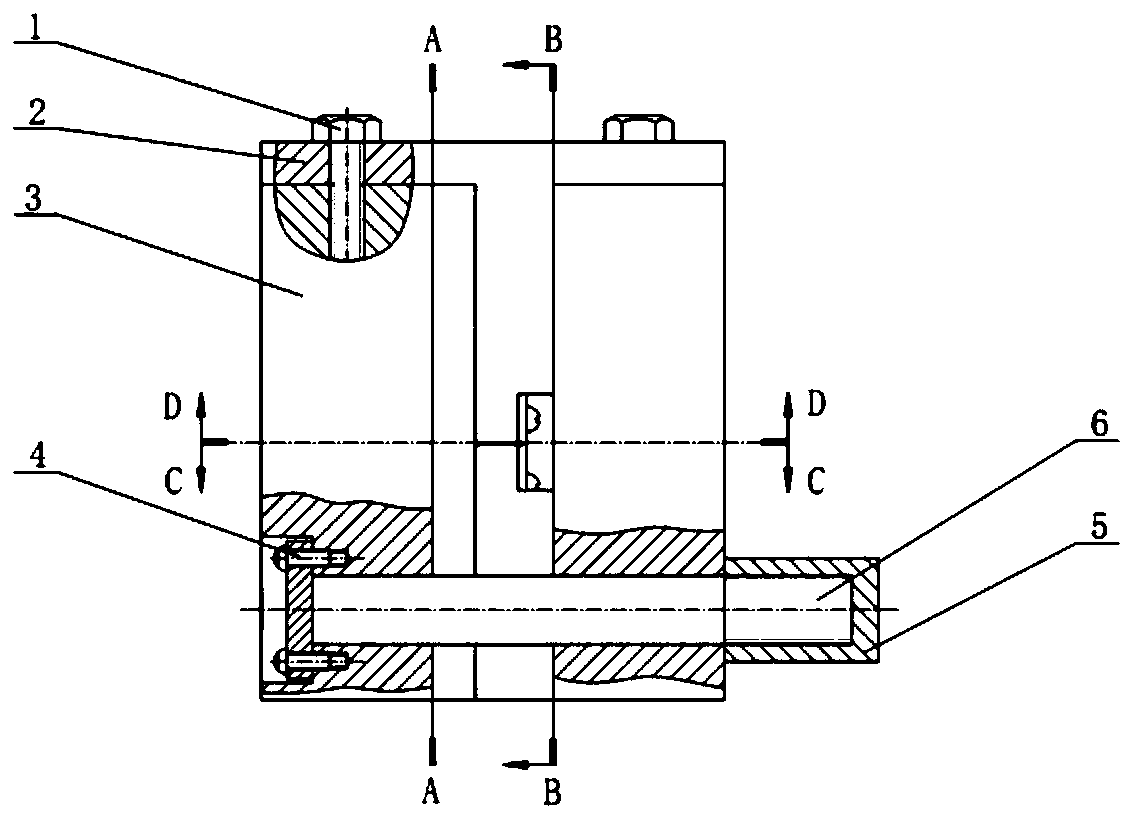

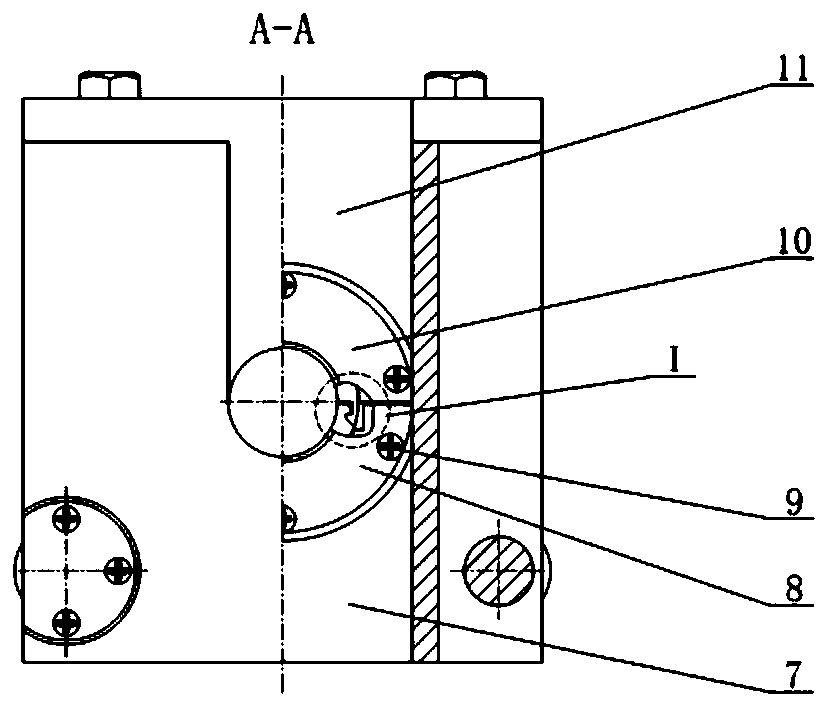

[0065] The carbon fiber bundle sample preparation device includes a pre-compression straightening assembly, a constraining ring assembly and an edge trimming assembly.

[0066] Such as Figure 1 to Figure 6 As shown, the preloading and straightening assembly includes: a first bracket 3, a second bracket 14, two T-shaped briquetting blocks 2, a guide rail 6, a positioning nut 5, a sleeve 17 and a connecting fastener; wherein the connecting fastener includes Hex head bolt 1 and screw A4.

[0067] The connection relationship is as follows: the first bracket 3 and the second bracket 14 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com