Textile spinning product quality control method and special equipment based on elastic curve of two-dimensional area sample

A quality control method and elastic curve technology, applied in the direction of testing the hardness of materials, etc., can solve the problems that the quality of textile fabrics cannot be accurately measured and detected, and achieve the effects of convenient programming automation, small calculation load, and reduced interference from random factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1, sampling and sampling.

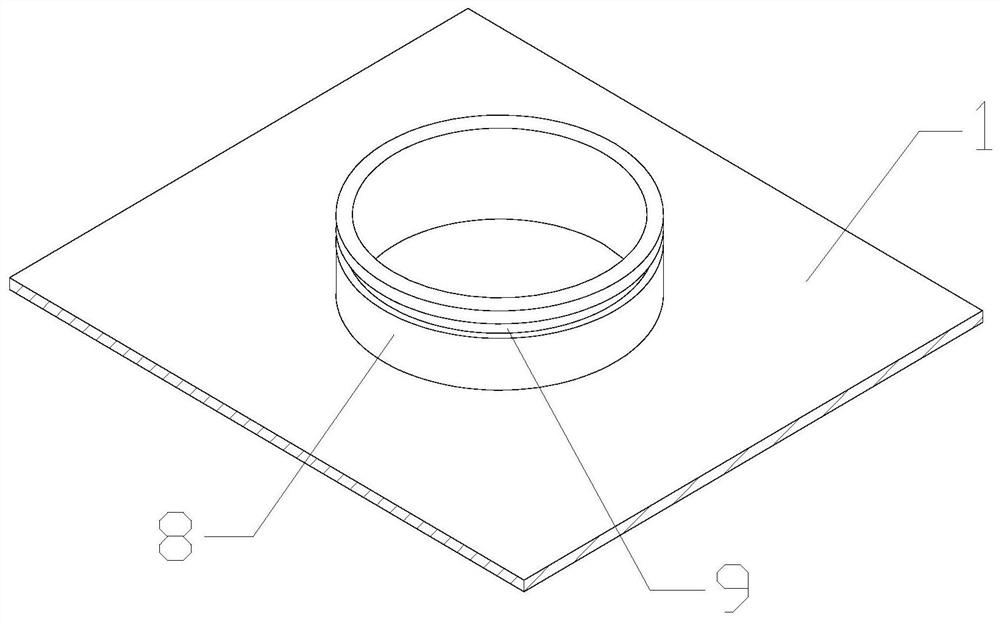

[0038] Sampling of textile spinning products according to the established frequency in the industrial process, assign and record the sampling number after sampling; then carry out discrete sampling on the two-dimensional plane of the sampling sample to obtain textile spinning sampling samples, and the sampling samples are round or square , whose area is not greater than 100cm 2 ;The spatial distribution of sampling samples on the two-dimensional plane is determined according to the shape of the sampling samples; after the sampling is completed, assign and record the sampling number for each group of sampling samples; the spatial distribution of sampling samples on the two-dimensional plane is determined according to the shape of the sampling samples, generally are rectangular.

Embodiment 2

[0039] Embodiment 2. Acquisition of elastic discrete values.

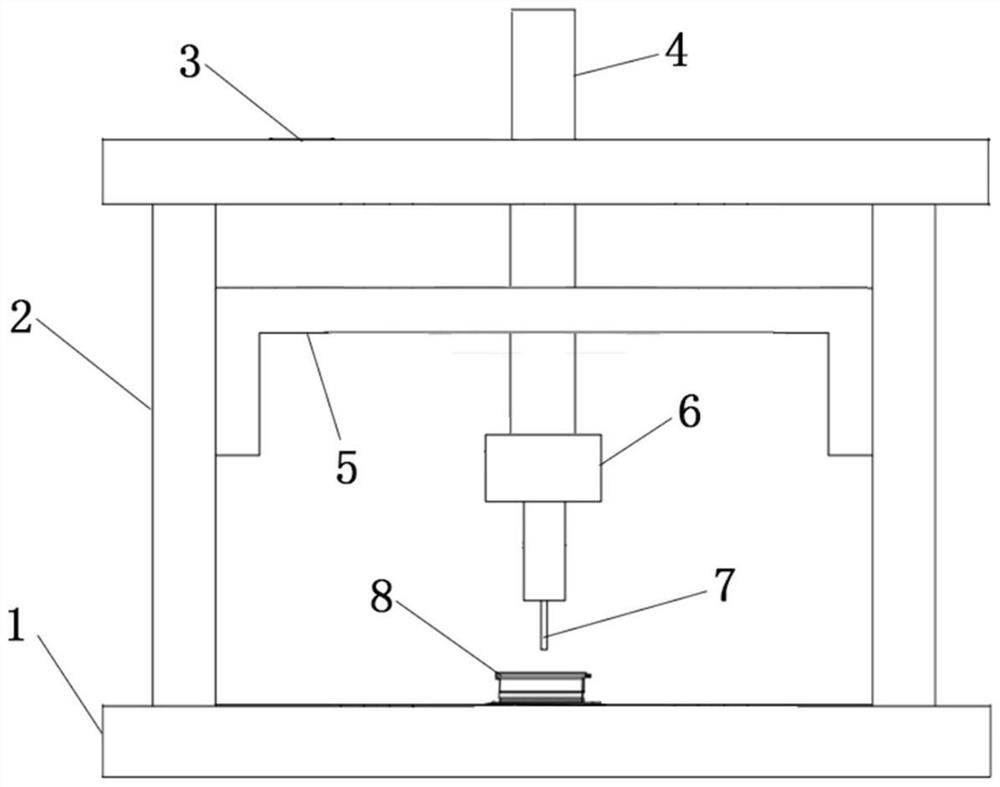

[0040] Fix the sampling sample obtained in the previous step on the sample platform of the elastic testing machine. After starting up, the pressure punch with the timing circuit will move toward the sampling sample at a constant speed. After touching the sampling sample, the pressure sensor behind the pressure punch will start recording From the dynamic elastic data of the sampling sample, until the sampling sample breaks, the discretized elastic data at different times are obtained.

Embodiment 3

[0041] Embodiment 3, the acquisition of elastic continuous curve.

[0042] Set up a group of programmable microcontrollers, connect the signal input terminal of the pressure sensor on the elastic testing machine with the signal input terminal of the programmable microcontroller, and automatically input the data in Example 2 to the programmable microcontroller, and then perform data processing:

[0043] 3-1. Normalization processing:

[0044] 3-1-1. First, perform zero-point normalization processing on each set of data in the time dimension, set the time point corresponding to the initial elastic data in each set of data as the initial time point, and set the time point corresponding to each subsequent elastic data Points for peer-to-peer translation normalization;

[0045] 3-1-2. Then perform global normalization of time dimension on each set of data, and assign a global coefficient to the time span after zero-point normalization, so that the time span of each set of samples ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com