A data synchronization correction method based on material balance

A material balance and correction method technology, applied in the field of data correction, can solve problems such as inaccurate correction results, failure to consider significant material correction, and affect material balance results, etc., to achieve the effect of facilitating engineering implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

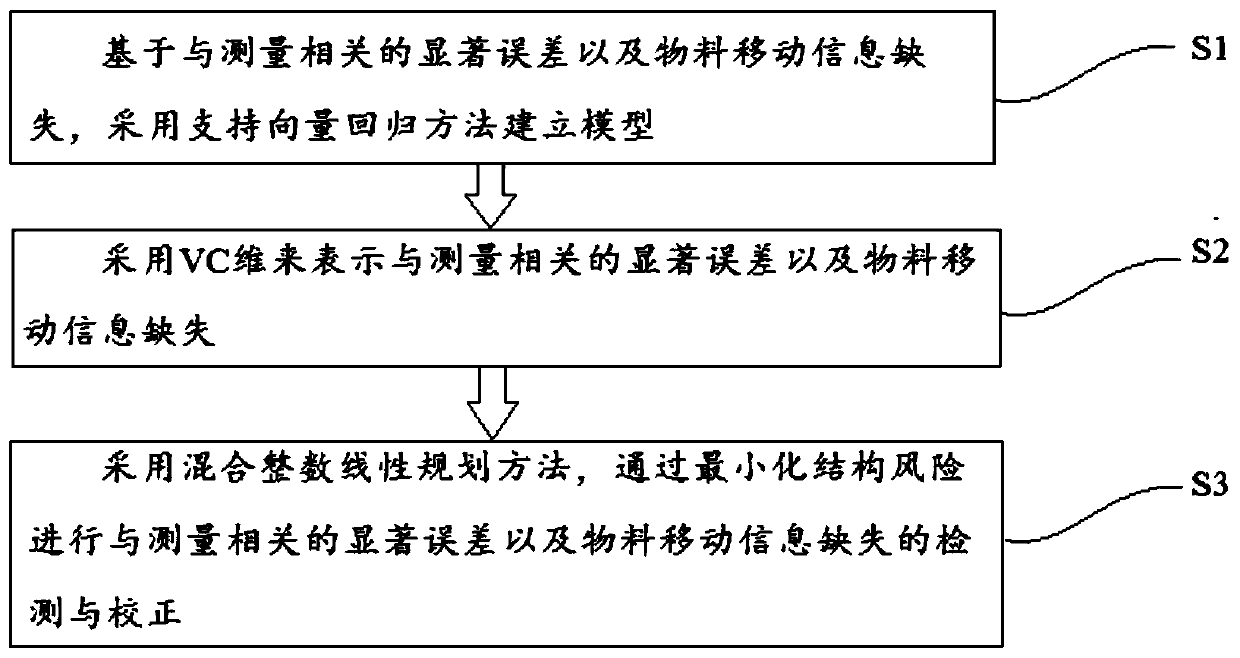

Method used

Image

Examples

example 1

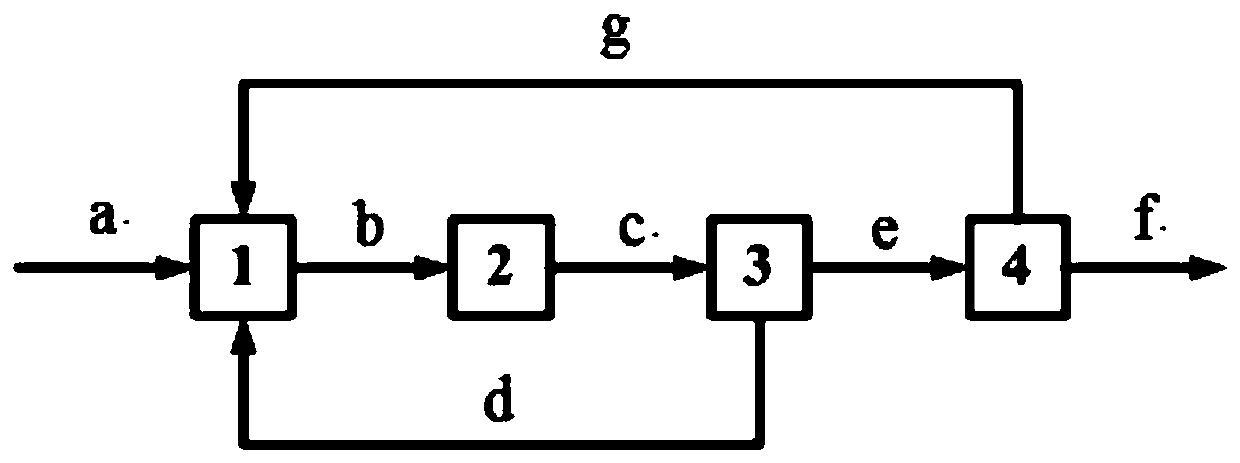

[0094] Process leakage can also be seen as a lack of material movement information, which can cause serious material imbalances in the material balancing process. This example uses a circulatory system as the research object, which is a linear system, which is also used by many scholars to study data coordination problems, especially to study process leakage. The structure of the system is as figure 2 As shown, there are seven flows a, b, c, d, e, f, g and four device node units 1, 2, 3, 4, and the actual values of the flows are [5,15,15,5,10 ,5,5](m 3 / h), the standard deviation (SD) of measurement is all 2.5% of the true value, all the data in the simulation adopt the average value of ten measurements, and the simulation results are obtained based on 100 simulation data by Monte Carlo method.

[0095] The purpose of the research carried out with this system in this example is to reveal the detection efficiency of the method of the present invention for significant error...

example 2

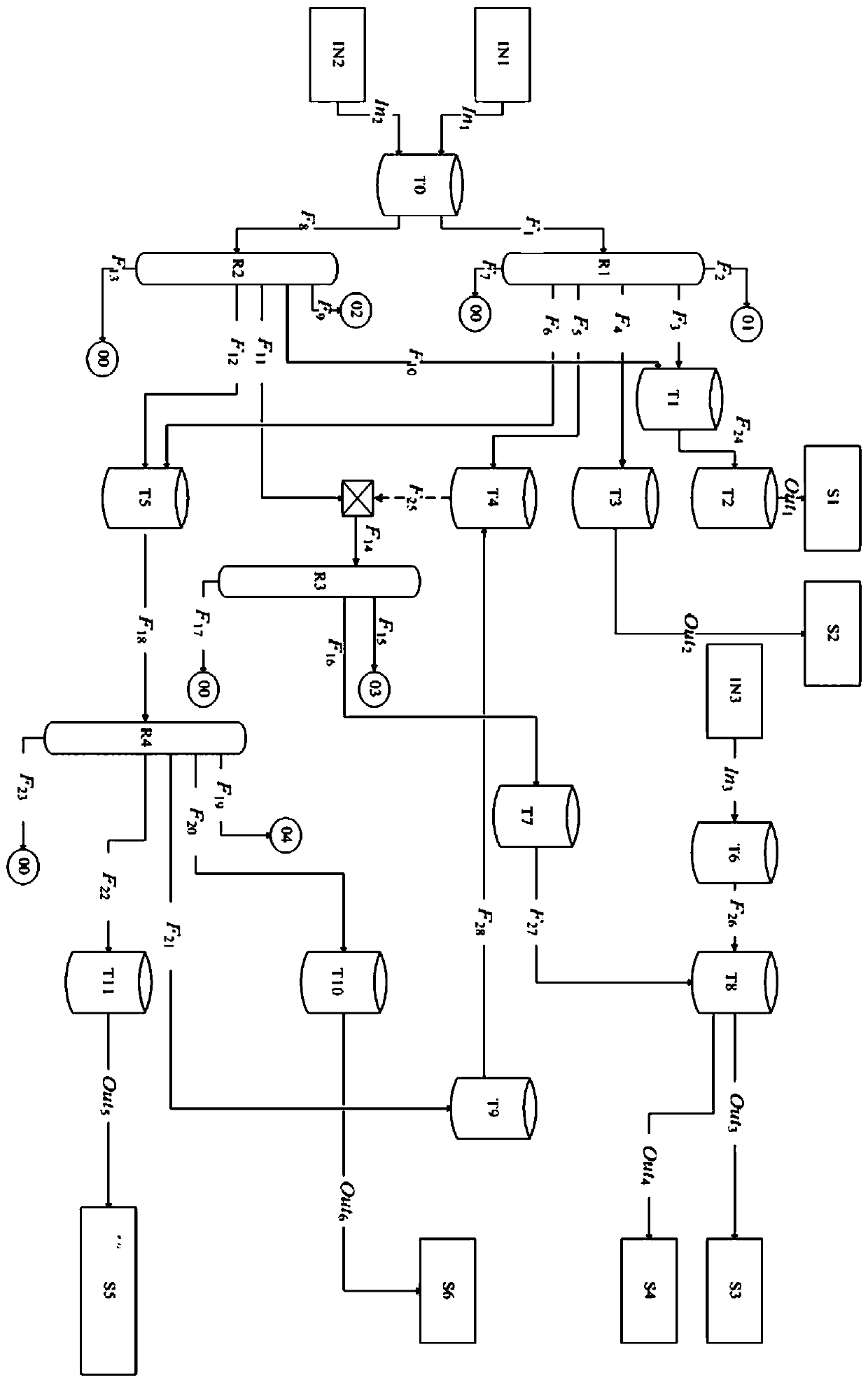

[0112] Petrochemical is a typical process industry. During the production process, petrochemical products flow from one processing unit to another. The movement of materials in the whole plant forms a complex material balance network. In this example, part of the actual processing flow in a certain oil refinery is used to form a material balance network to illustrate the implementation of the method of the present invention to simultaneously correct significant measurement errors and missing material movement information in material balance.

[0113] By merging and simplifying the material pipe network, devices and storage tanks in the actual production process, a simplified material balance network can be obtained, such as image 3 shown. The material balance network includes 4 processing units (R 1 to R 4 ), 9 incoming and outgoing nodes (IN 1 to IN 3 , S 1 to S 6 ), 12 tanks (T 0 to T 11 ) and 28 material streams (F 1 to F 28 ). The relevant model data are shown ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com