Method for processing waste incineration fly ash and garbage concentrated solution through synergetic curing

A waste incineration fly ash and treatment method technology, applied in waste treatment, solid waste removal, etc., can solve the problems of harsh conditions and high costs, and achieve the effect of reducing solidification costs, reducing the use of cement, and reducing the occupied storage capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

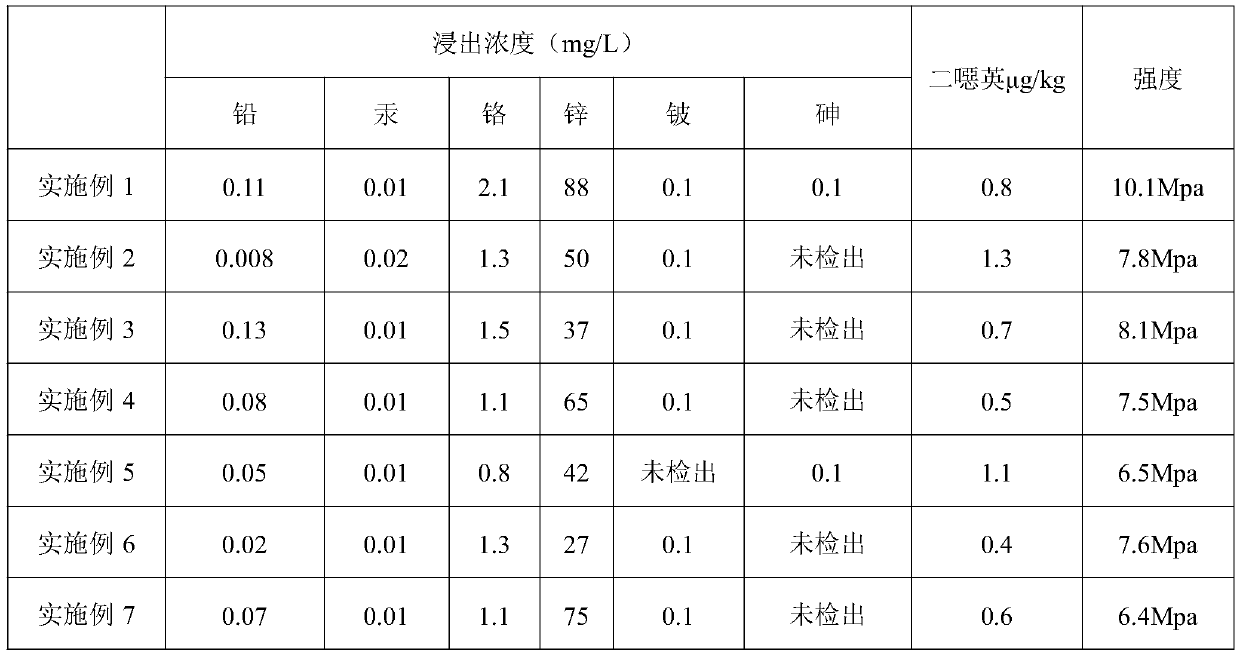

Examples

Embodiment 1

[0028] A treatment method for synergistic solidification of waste incineration fly ash and waste concentrate, comprising the following steps:

[0029] The total mass of all solid materials in this embodiment is 50kg;

[0030] (1) take by weighing 15kg of dry waste incineration fly ash;

[0031] The curing base material is 19.5kg, and the curing base material is composed of fly ash, iron ore tailings powder, desulfurized gypsum and red mud, including 7.5kg of fly ash, 5kg of iron ore tailings powder, 5kg of desulfurized gypsum, and 2kg of red mud;

[0032] 10.5kg of curing agent, the curing agent is composed of bentonite, zeolite and cement, of which 5kg of bentonite, 2kg of zeolite and 3.5kg of cement;

[0033] Put the waste incineration fly ash, curing base material and curing agent into the dry material mixer for mixing and stirring, and stir evenly for 3 minutes to form a solid mixture;

[0034] (2) Add 25 kg of garbage concentrate to the solid mixture, and continue to st...

Embodiment 2

[0038] A treatment method for synergistic solidification of waste incineration fly ash and waste concentrate, comprising the following steps:

[0039] The total mass of all solid materials in this embodiment is 50kg;

[0040] (1) Take by weighing 17.5kg of dry waste incineration fly ash;

[0041] The curing base material is 17kg, and the curing base material is composed of fly ash, iron ore tailings powder, desulfurized gypsum and red mud, including 6kg of fly ash, 5kg of iron ore tailings powder, 4kg of desulfurized gypsum, and 2kg of red mud;

[0042] 11.5kg of curing agent, the curing agent is composed of bentonite, zeolite, and cement, of which 4kg of bentonite, 3kg of zeolite, and 4.5kg of cement, put the waste incineration fly ash, curing base material and curing agent into the dry material mixer for mixing and stirring, evenly 2 minutes to form a solid mixture;

[0043](2) Add 25 kg of garbage concentrate to the solid mixture, and continue to stir for 2 minutes to for...

Embodiment 3

[0047] A treatment method for synergistic solidification of waste incineration fly ash and waste concentrate, comprising the following steps:

[0048] The total mass of all solid materials in this embodiment is 100kg;

[0049] (1) take by weighing 40kg of dry waste incineration fly ash;

[0050] The curing base material is 27kg, and the curing base material is composed of fly ash, iron ore tailings powder and desulfurized gypsum, including 12kg of fly ash, 10kg of iron ore tailings powder, and 5kg of desulfurized gypsum;

[0051] 26kg of curing agent, the curing agent is composed of diatomite, zeolite and cement, wherein 8kg of diatomite, 6kg of zeolite and 12kg of cement are put into the dry material mixer to mix and stir the waste incineration fly ash, curing base material and curing agent, Stir evenly for 10 minutes to form a solid mixture;

[0052] (2) Add 60 kg of garbage concentrate to the solid mixture, and continue stirring for 10 minutes to form a uniform slurry-lik...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com