Double-MCU digital PI and PWM control multifunctional welding machine and circuit structure thereof

A circuit structure, multi-functional technology, applied in the direction of manufacturing tools, welding equipment, arc welding equipment, etc., can solve the problem of poor resistance to network voltage fluctuations of welding machines, reduce weight and transportation costs, facilitate production, and control connecting lines. less effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

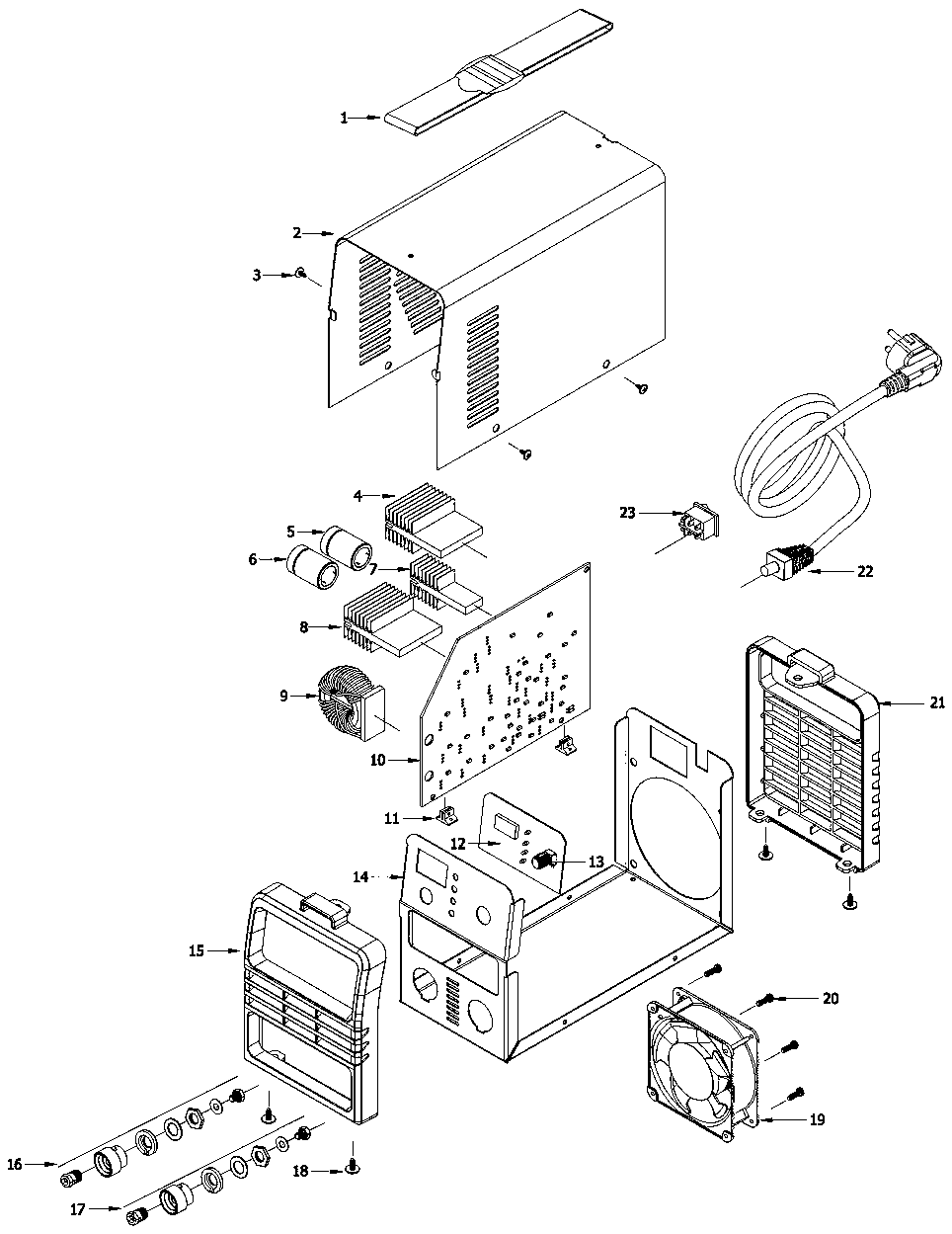

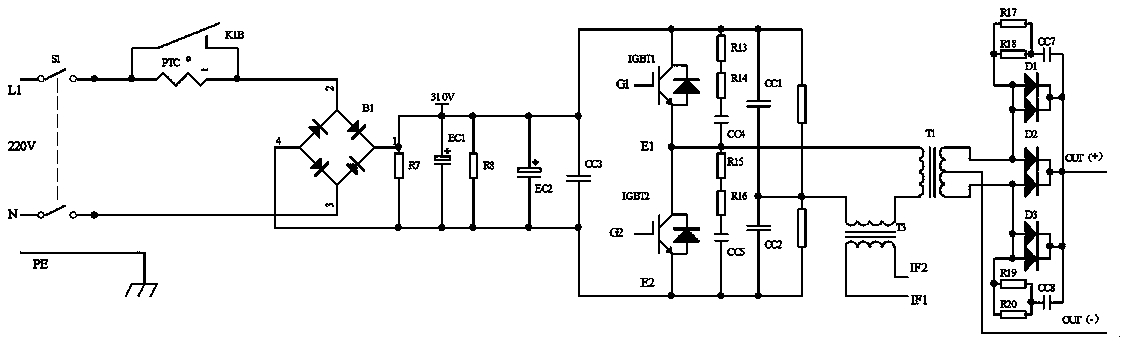

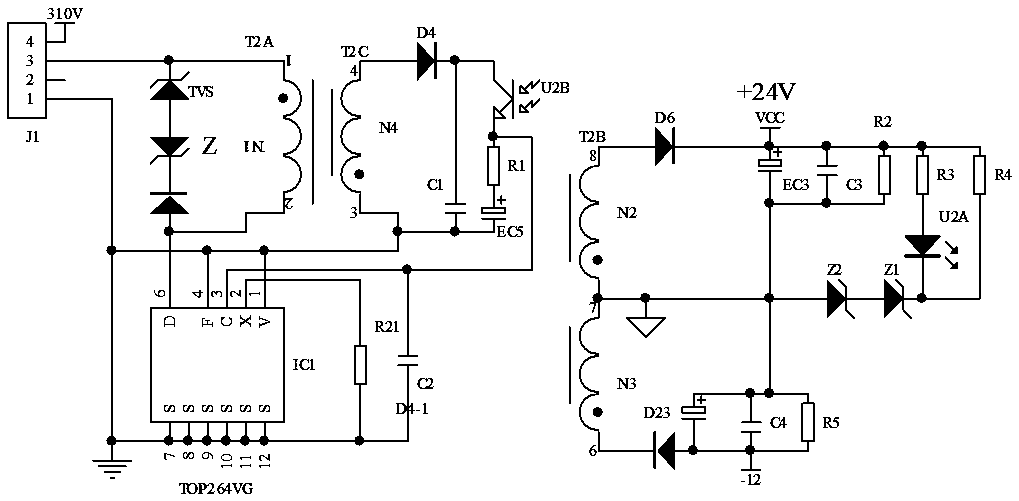

[0025] The invention relates to a dual-MCU digital PI and PWM control multifunctional welding machine and its circuit structure. The welding machine can adopt international general power supply of 220V-240V, 50 or 50Hz. It has two welding methods, manual arc welding and argon arc welding, which can be selected by touch buttons; it has VRD function and VRD indication; it has overheat protection control and indication; digital display of welding current parameters; a circuit composed of 8-bit microprocessor as the core Control the display of welding parameters; the circuit composed of 32-bit microprocessor as the core realizes the selection and control of two welding methods: manual arc welding and argon arc welding; current given signal and current negative feedback digital PI (proportional + integral) operation control ; Digital control PWM signal output; characteristics of VRD, overheating, argon arc welding (TIG) and manual arc welding (MMA) control status indication.

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com