Robot for clearance measurement-compensation during composite assembly and clearance compensation method

A robot and gap technology, applied in the field of robots and gap compensation, can solve the problems of not finding robots, low degree of automation, relying on manual operation, etc., to achieve the effect of accurate three-dimensional shape of assembly gap, improve assembly efficiency, and reduce waste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

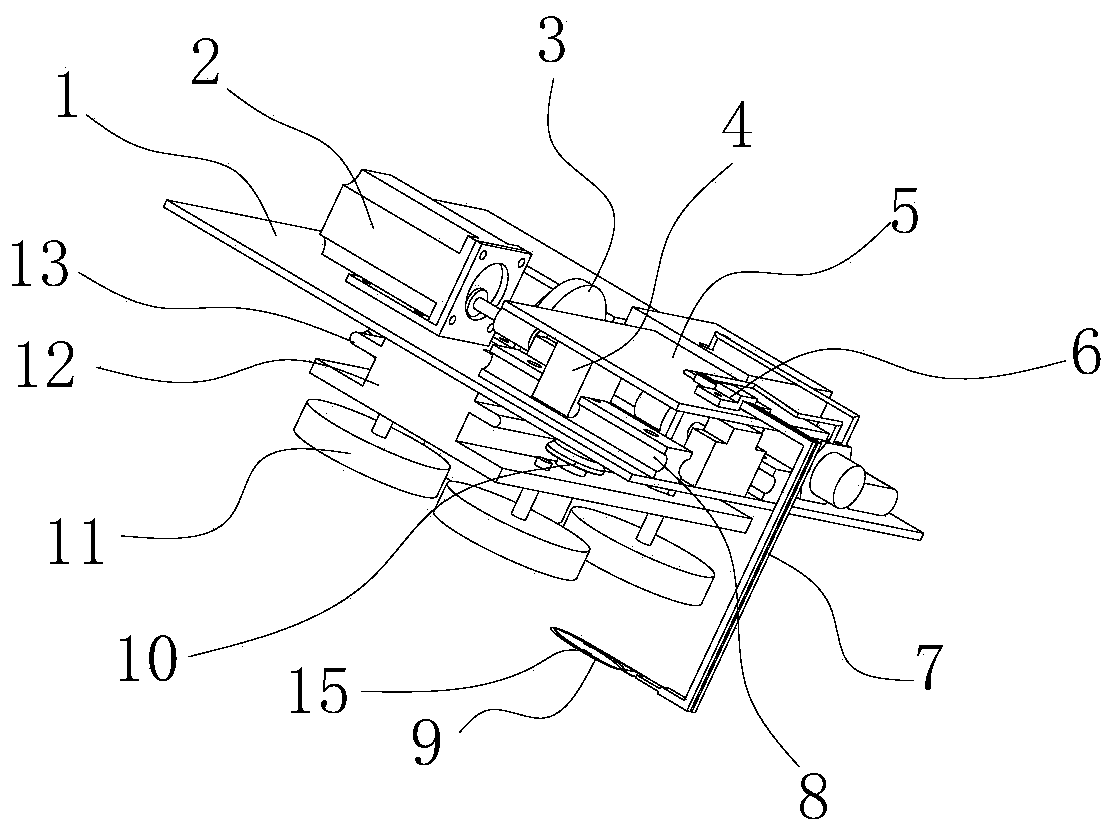

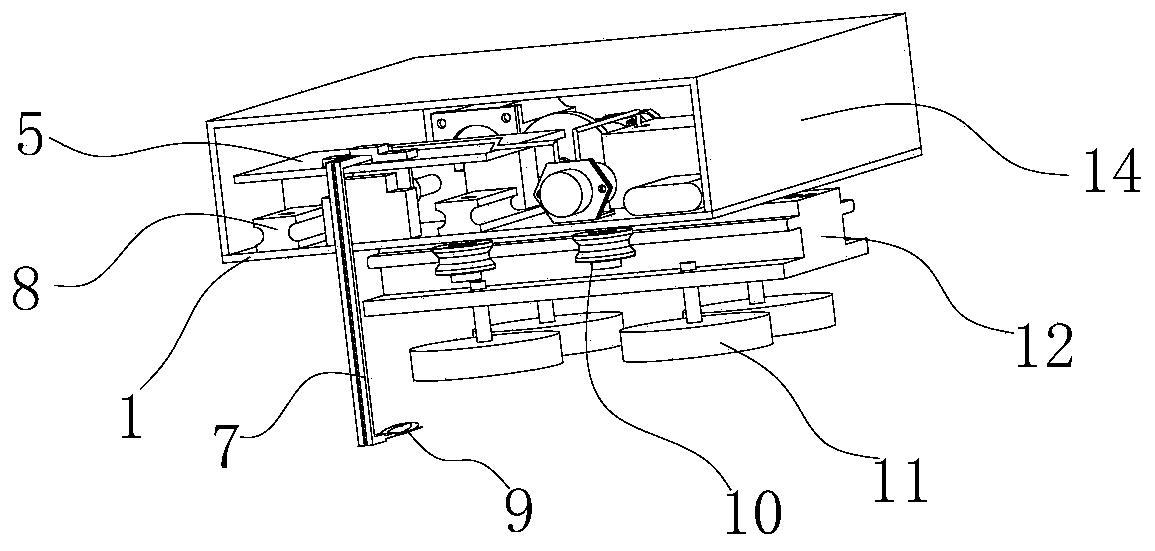

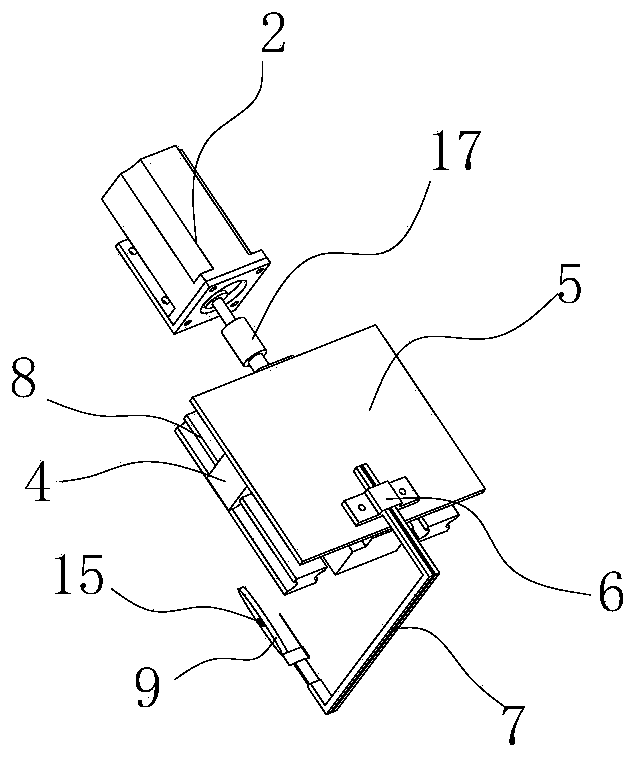

[0037] This embodiment is a robot for gap measurement-compensation in composite material assembly, such as figure 1 and figure 2 As shown, it consists of an integrated motion device, a gap measurement device, a gap compensation device and a control device.

[0038] The integrated motion device such as figure 1 , figure 2 and Figure 6 As shown, it includes a guide rail 12 and a chassis 1, the bottom of the guide rail 12 is fixed with a plurality of vacuum chucks 11, the two sides of the guide rail 12 are provided with strip-shaped flanges 13 along the length direction, and the bottom of the chassis 1 Two rows of rollers 10 are installed, the rollers 10 are provided with annular grooves matching the flanges 13, and the flanges 13 on both sides of the guide rail 12 are snapped into the two rows of rollers 10 so that the chassis 1 is attached to the On the guide rail 12; the top of the chassis 1 is installed with a geared motor 16 for driving the roller 10 to move along the...

Embodiment 2

[0045] In this embodiment, the gap compensation method of the composite material component of the robot is used in the first embodiment, and a composite material wing box is selected as the research object. The used wing box is as follows: Figure 8 Shown, comprise seven components such as front beam 26, rear beam, left rib, middle rib, right rib, upper wall plate and lower wall plate 25, connect by high lock bolt between each part. Among them, the front beam and the rear beam are both carbon fiber epoxy resin composite laminates, formed by a male mold, with a C-shaped cross section, and cured by an autoclave. The material of the three wing ribs is aluminum alloy, which is cut into the final shape by CNC machining. The upper and lower panels are composite laminates cured in an autoclave using a female mold. Due to the molding errors of the front and rear beams and the upper and lower panels, gaps are created between the mating surfaces of the panels and beams. In this exampl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com