Motorcycle hub composite electroplating method

A composite electroplating and motorcycle technology, applied in the field of electroplating, can solve the problems of high processing cost, low processing cost, poor universality, etc., and achieve the effect of high production rate, saving process cost and less process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with the examples.

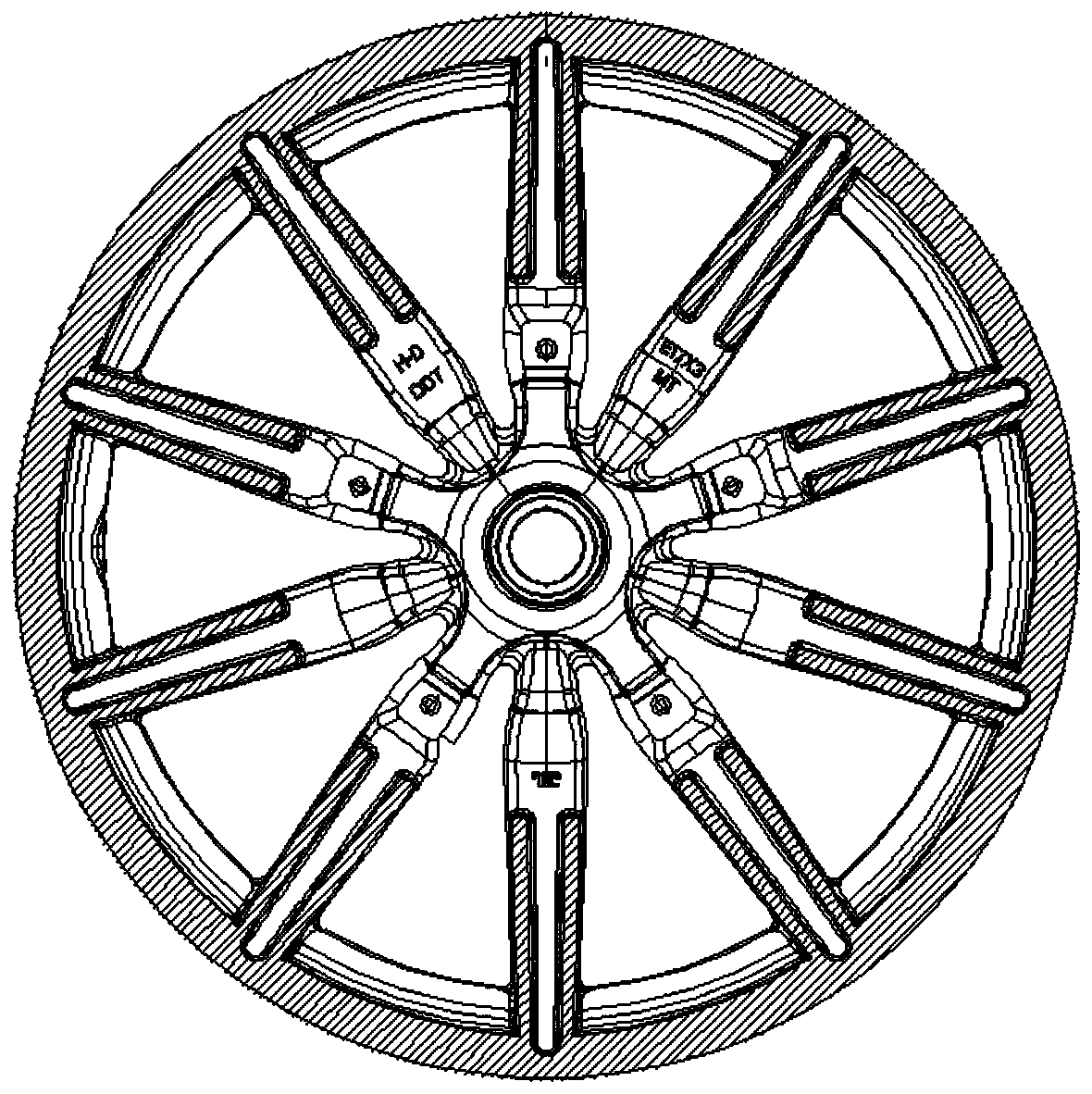

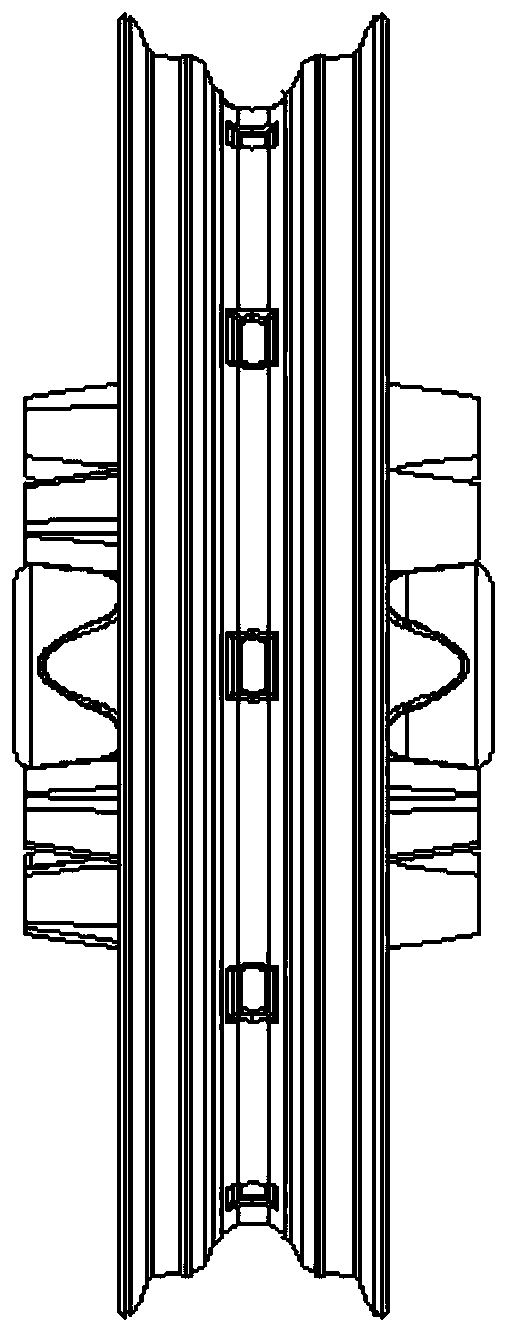

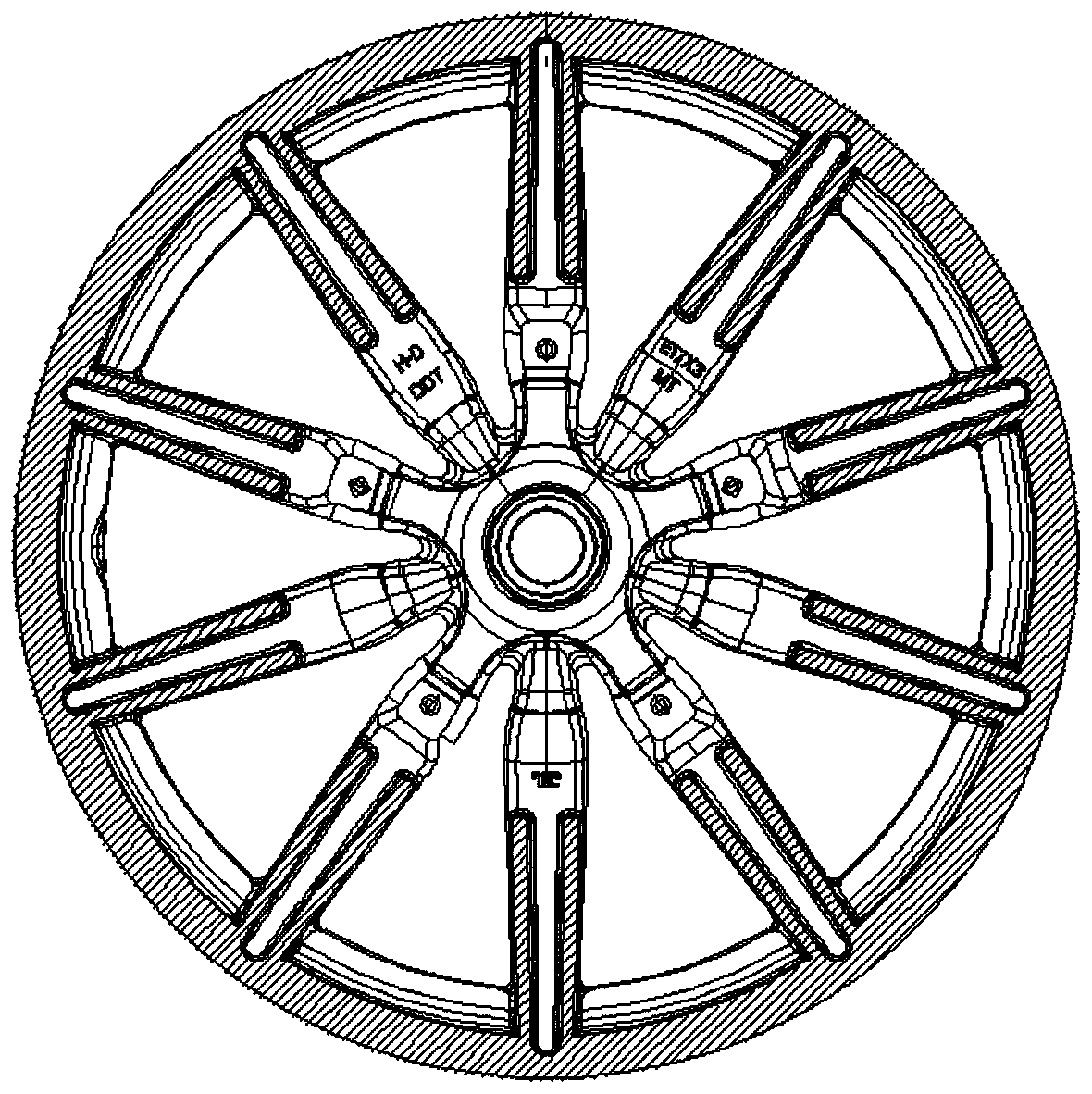

[0034] Such as figure 1 , 2 Shown, the motorcycle wheel hub composite electroplating method comprises the following steps:

[0035] a. Adopt metal mold to cast a motorcycle aluminum alloy wheel hub blank of predetermined shape, but various irregular geometric shapes or regular geometric shapes, this process is not limited by the shape of motorcycle hub; the wheel hub of this embodiment is figure 1 Shape, hatching area is electroplating area, other area is painting area, for rough machining:

[0036] 1) Fine grinding: Use different types of sandpaper to smooth out the burrs, particles, impurities, etc. on the surface of the hub to make the surface of the hub smooth;

[0037] Specifically, after heat treatment and solid solution aging, sandpapers of different thicknesses are used to polish in sequence to make the surface smooth, and then sandblasting is carried out with steel shot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com